Claas is extending its combine harvester range below the TRION and LEXION series with three new five-walker machines. The new EVION range is equipped with modern Cummins six-cylinder engines and the Cemis 700 control concept.

The EVION has been designed for family farms as well as for contractors and agribusinesses with smaller field sizes. It is available in Classic and Maxi versions and with a choice of Trend or Business equipment lines.

The arrival of the EVION completes the restructuring of the entire Claas combine harvester range which began with the new LEXION in 2019. As successors to the AVERO and smaller TUCANO models, these three five-walker combine harvesters round out the lower end of the range below the TRION.

“The EVION is a very important product for Claas”, explains Claas CEO Jan-Hendrik Mohr who is also responsible for the Grain Business Unit. “With these three new combine harvesters we are able to offer modern, yet affordable machines for smaller-scale farms which want their own grain harvesting equipment. We’re a family business ourselves and we want to continue to offer the right machines for smaller farms across all our product segments.”

The technology of the EVION is based on a modular system which is used to build almost 40 versions of the LEXION and TRION. “For the EVION, we are drawing on tried and trusted technology which has proven itself in thousands of machines”, Mohr continues. “In order to meet the differing requirements of our customers, the EVION 430 and 450 are available in either Classic or Maxi form, as was the case with the legendary Dominator. All the variants, including the EVION 410 Classic, can be ordered with either the Trend or the Business equipment line for further individualization. On top of this, our customers can choose additional options which are independent of the equipment line.”

Straightforward threshing

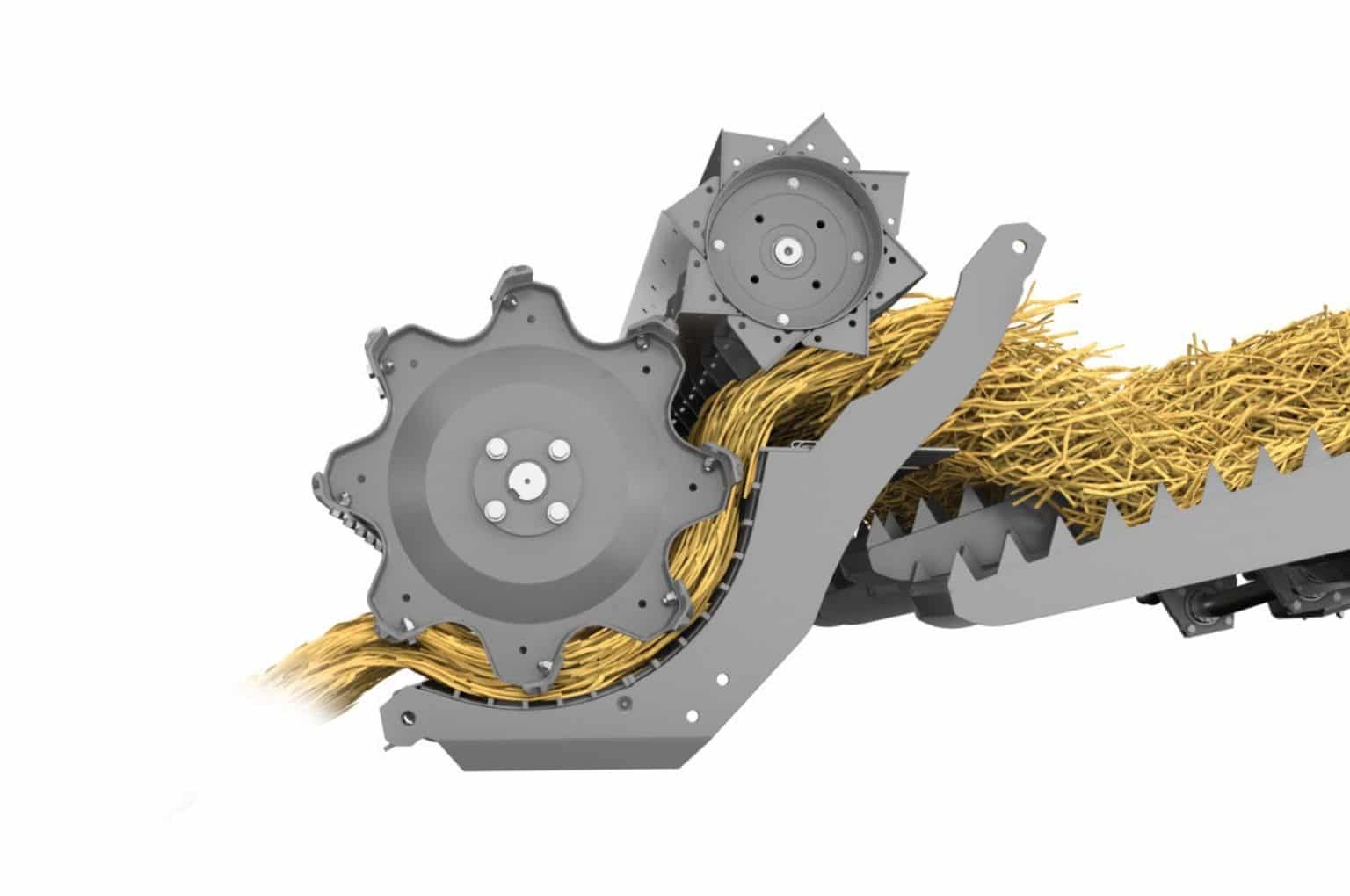

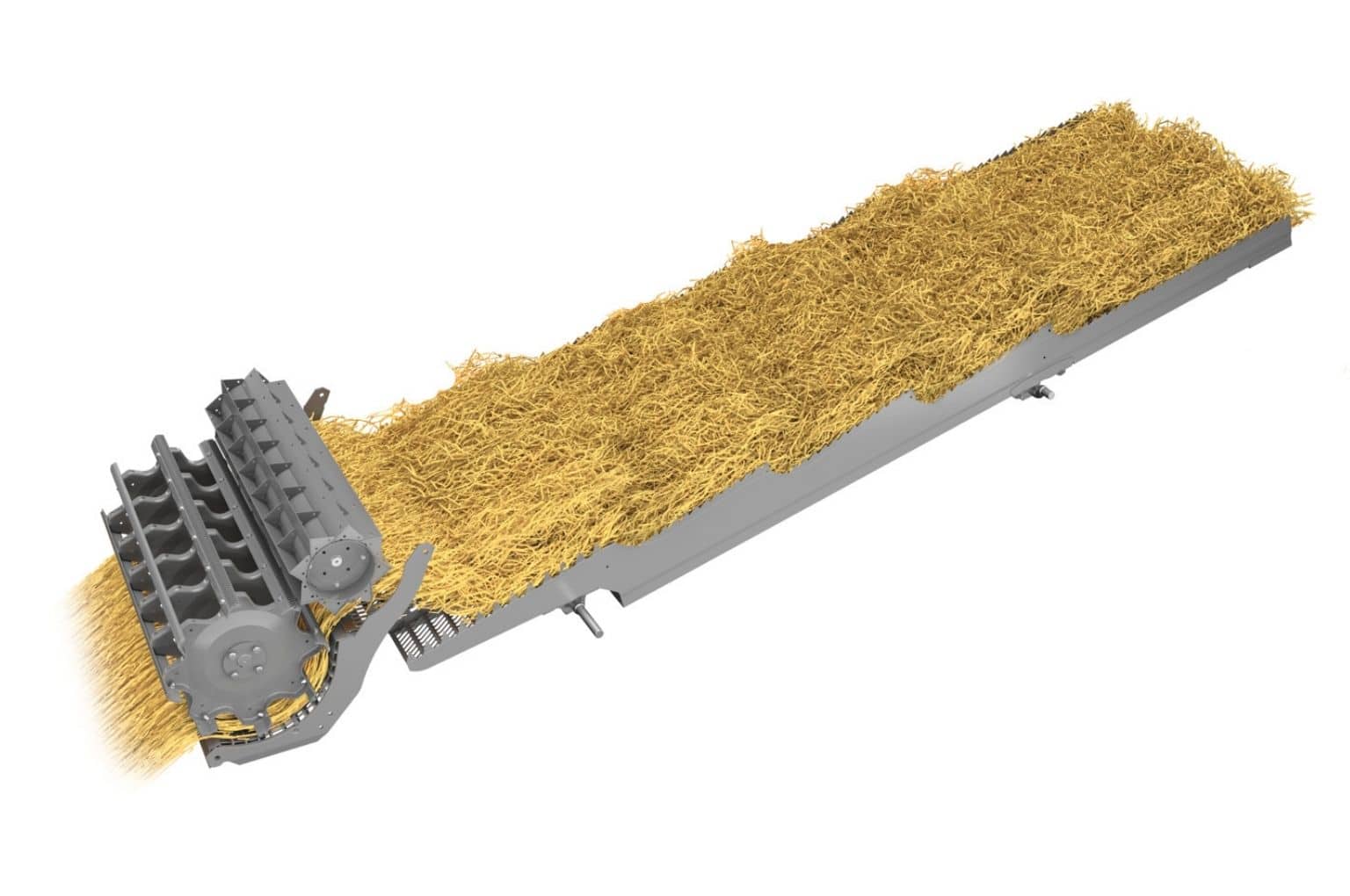

As well as focusing on using high-quality, proven components, delivering threshing quality and ensuring operating reliability, even under difficult harvesting conditions, the development team ensured that the EVION is easy to use. It is therefore equipped with a single-drum tangential threshing unit with a large, 600 mm threshing drum and a synchronised impeller combined with five 4.40-metre-long straw walkers and a feeder housing width of 1,420 mm. This results in a threshing concave area of 0.95 m2 and a separation area of 6.25 m2 provided by the straw walkers. Complemented by the standard pre concave flaps under the threshing drum, this arrangement enables high throughput while also delivering excellent grain quality.

The threshing drum speed is infinitely adjustable from the CEMIS 700 terminal. A speed range of 480 to 1,150 rpm (420 – 1,080 rpm with reduction kit) can be used in the EVION CLASSIC, while the EVION MAXI with its two-stage belt drives supports speed ranges of 220 to 630 and 415 to 1,150 rpm. Concave clearance adjustment is performed hydraulically from the cab and features integrated overload protection provided by a diaphragm accumulator to prevent blockages from occurring in the threshing unit. As the threshing concave in both the CLASSIC and the MAXI versions of the EVION is a MULTICROP unit, conversion measures are only needed rarely, if ever, when switching between common threshing crops. When conversion is required, the concave segments can be swapped out easily through the stone trap. For maize threshing, cover plates can be fitted between the eight rasp bars.

In order to provide more effective secondary separation and greater throughput, the centre risers of the straw walkers have been redesigned to loosen the crop mat even more effectively and to enable a faster transfer to the next straw walker racks. Another important factor, in addition to the threshing concave overload protection in ensuring operating reliability, is the sensor-based monitoring of the crop flow on the straw walkers. As soon as any blockages begin to develop there as a result of difficult harvesting conditions, the operator receives early warning both in the form of an audible alarm and as a visual alert on the CEMIS 700 terminal display. In addition, the optional CEMOS AUTO CROP FLOW automatically deactivates the front attachment and the feeder unit in the event of any imminent risk of blockages on the threshing drum or serious belt slippage so that no more crop is fed in. This avoids unnecessary downtime.

High-performance cleaning

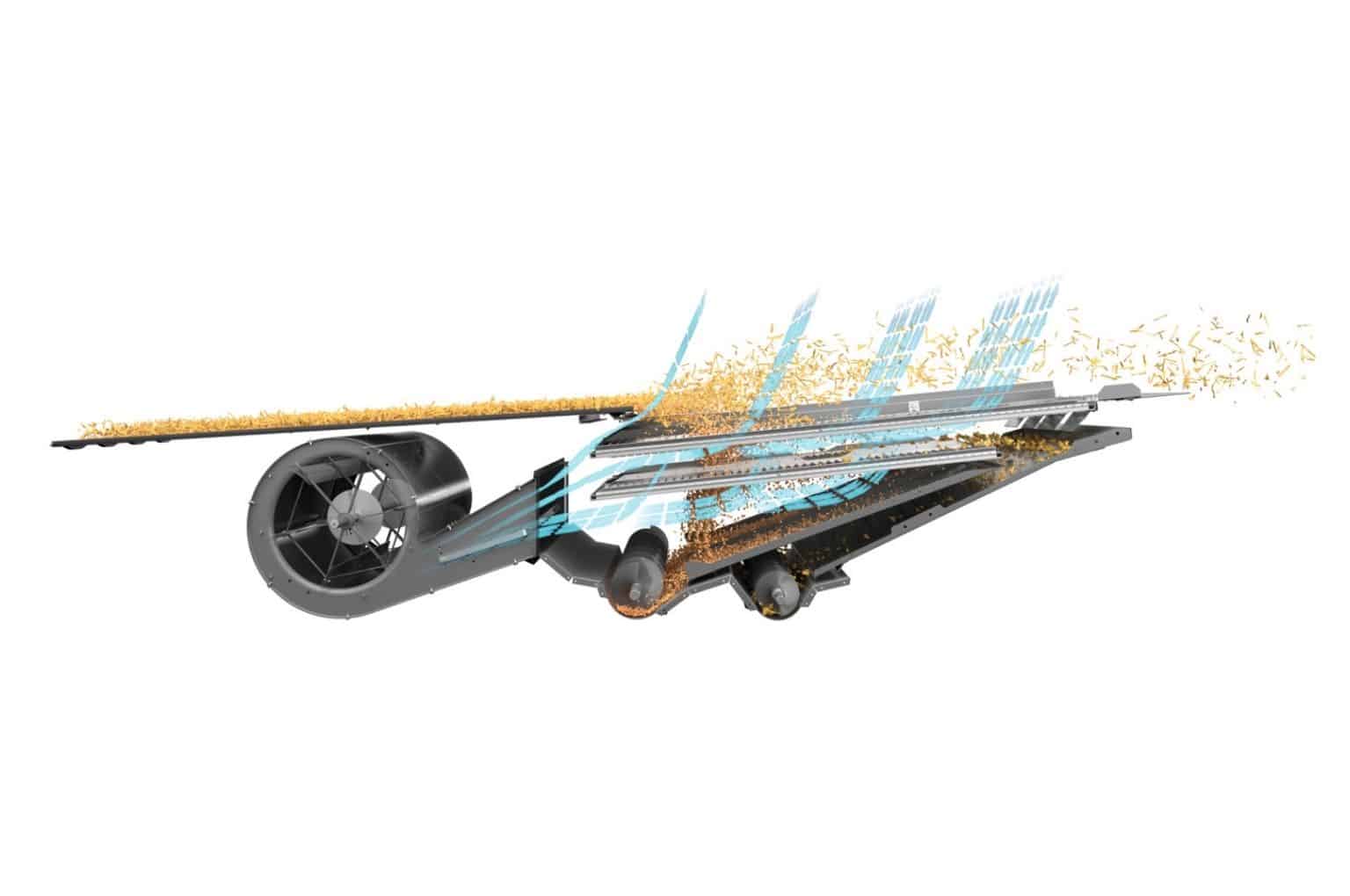

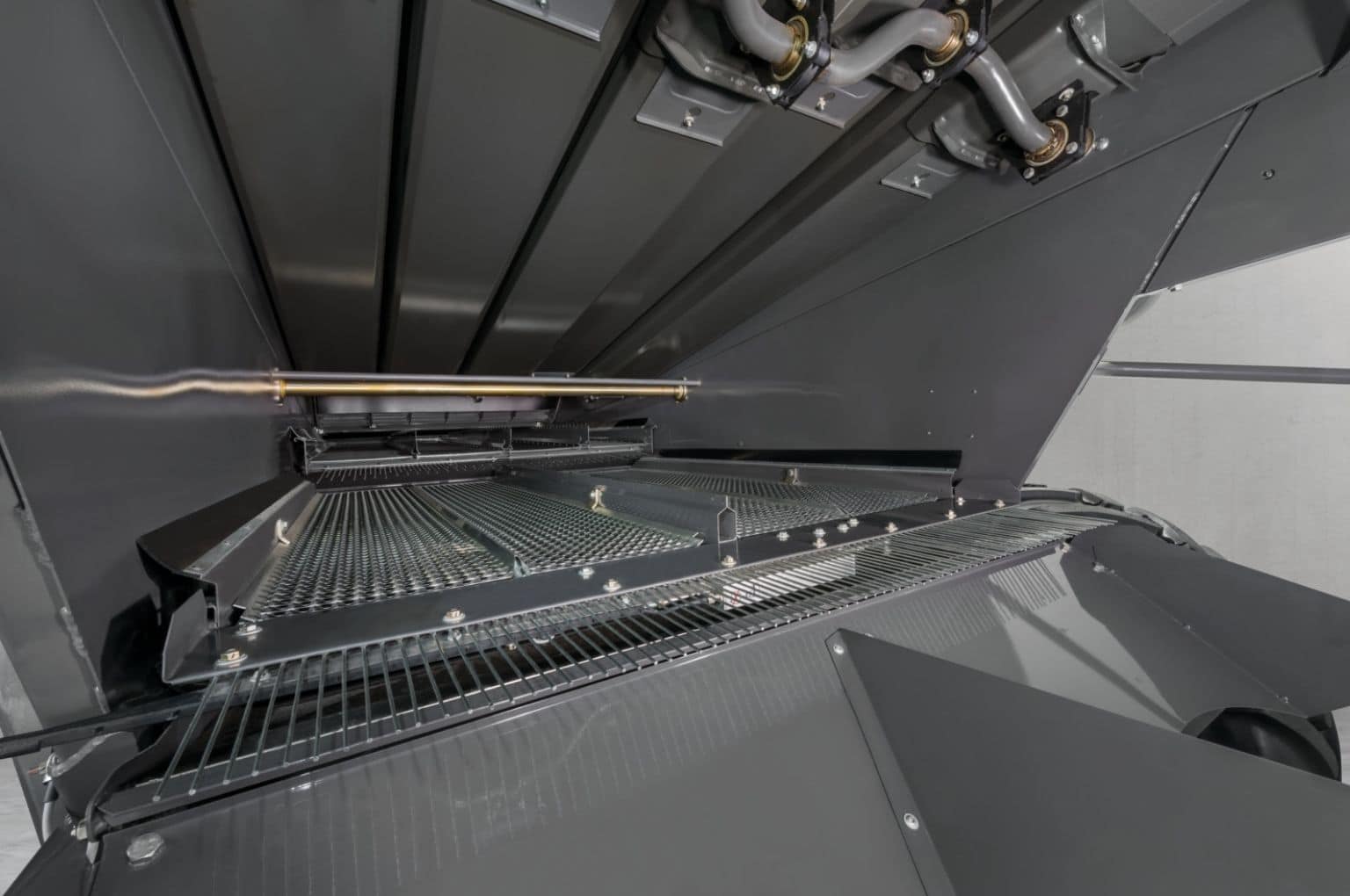

Despite the compact exterior dimensions of the EVION, the development team were able to integrate an efficient cleaning system. The sieve pan works with the upper and lower sieves moving in opposite directions and has a total sieve area of 4.80 m2. The sieve design, which features frogmouth openings with optimised flow characteristics, has already proven itself in the LEXION and TRION under varied operating conditions.

In addition to electric sieve adjustment, the standard equipment for all EVION models includes a loss measurement system. Adjustment of the speed of the radial fan is performed from the cab – and can even be controlled automatically with the optional AUTO SLOPE functionality when harvesting uphill or downhill. An inspection window allows the returns to be viewed conveniently from the operator’s seat. The 3D cleaning system, which is able to compensate for a lateral tilt of up to 20 percent when harvesting on slopes, is standard for the BUSINESS equipment line and option for the CLASSIC.

Large grain tanks and powerful elevators

The grain tank integrated behind the cab holds 5,600 l in the EVION 410, 6,500 l in the EVION 430 and 8,000 l in the top-of-the-range EVION 450. Sensors alert the operator when the fill level reaches 70 percent and then 100 percent. In addition to this functionality, a large grain tank inspection window gives the operator a direct, comprehensive view of the fill level and grain quality. When it comes to unloading, all three EVION models benefit from the 330 mm diameter of the grain tank unloading tube and the resulting 90-litre-per-second unloading rate – meaning that offloading can be completed in 1 to 1.5 minutes. The 105-degree pivot angle of the grain tank unloading spout ensures that the operator always has a perfect view of the offloading process. A pivoting grain tank unloading tube spout, as already used in the TRION and LEXION, is available as an option to provide high-precision control of the grain stream directed at the transport vehicle.

Another argument in favour of the EVION models is to be found in the grain elevator whose increased conveying capacity of 34 l/s means that it has what it takes to harvest grain maize in high-yield sites with picking front attachments up to 6 rows wide.

Straw chopping and spreading

At medium to high-yield locations in particular, farmers attach great importance to good straw chopping and spreading. This is why, in a first for this class, the EVION is available with an optional 72-knife straw chopper as an alternative to the standard 52-knife version. Both shear bar and friction bar can be adjusted without tools while the switchover from chopping to swathing is performed at the right-hand side of the straw discharge hood. The straw guide plates are adjusted manually to the working width so that uniform distribution is ensured even when operating with a cutterbar width of 6.80 m. Chaff and short straw are distributed across the working width by optional, hydraulically driven chaff spreaders.

Cummins six-cylinder

Common to all three EVION models is the 6.7-litre Cummins B6.7 engine which meets the Stage V emission standard. This is the same common-rail six-cylinder unit used in the TRION and is notable for its ability to deliver high torque at low revs. The full rated output of 204 (EVION 410), 231 (EVION 430) and 258 hp (EVION 450) is available at just 1,900 rpm, while the idle speed is a low 800 rpm (1,200 rpm with active hydraulic functions). DYNAMIC POWER engine management ensures that the engine only delivers as much power as is actually required at any time. This system can reduce fuel consumption by up to 10 percent. When the grain tank unloading system is active, the highest output level is enabled automatically.

Access to the engine from the maintenance platform is easy, simply requiring the cover plate which provides protection from dust and dirt deposits to be raised to the open position with the support of two gas struts. A rotating radiator screen cleans the air intake area continuously. For daily cleaning tasks, an air compressor with three connection points – near the cab (for cab cleaning), at the left above the rear axle (cleaning of sieve and straw walker area as well as the drives on the right-hand side) and near the engine (cleaning of engine area) – is available as an option.

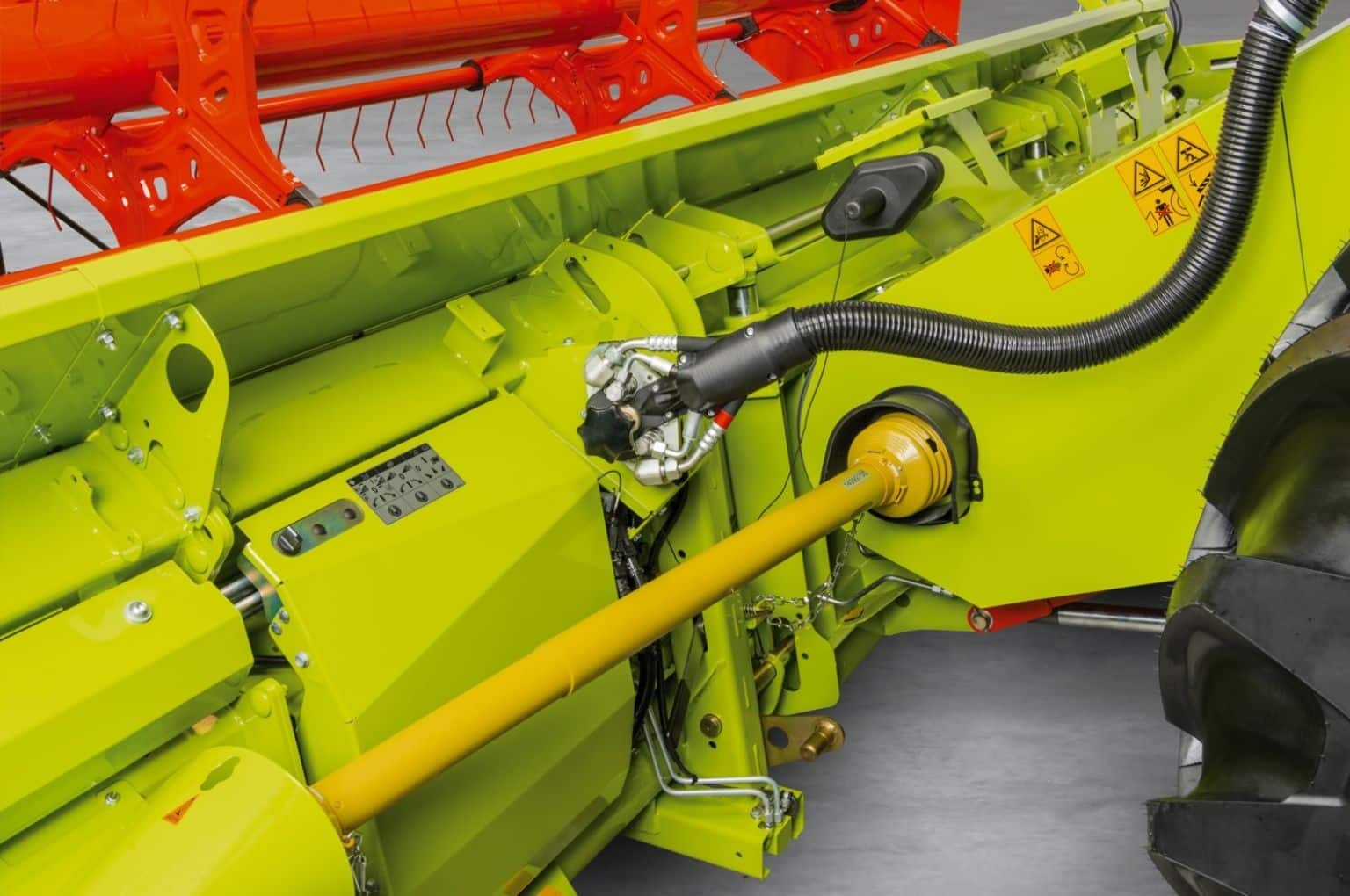

Power transmission to the various driven units of the machine is handled by a drive system based partly on components from the TRION and LEXION. The reel drive, feeder housing and front attachment reversing mechanism as well as the threshing drum and fan variator are operated hydraulically, which enables operating reliability in difficult and changing conditions. Other important units, such as the threshing unit variator, straw chopper, front attachment and grain tank unloading auger are activated and deactivated electro hydraulically. Belt tensioners, which are fitted as standard, simplify the system check at the start of each working day.

The ground drive is provided by a 3-speed, manually shifted hydrostatic drive. A choice of top speeds – 20, 25 or 30 km/h – is available. For the MAXI version, an electrically engageable differential lock is available for the front wheels which have a diameter of up to 1.85 m. For the rear axle, customers have a choice of wheels with a diameter of 1.35 m or, for maximum soil protection, as much as 1.50 m.

Spacious cab with CEMIS 700 and CMOTION

The spacious cab is equipped with a modern control armrest with the ergonomic CMOTION multifunction lever, the clearly laid-out keypad and the CEMIS 700 touchscreen terminal. The 7-inch CEMIS 700, which can be adjusted to the position that suits each operator best, has a high-contrast display that allows machine functions to be monitored easily, even in bright sunlight. The ability to call up saved settings for all common threshing crops allows the machine to be deployed quickly and enables easy, time-saving changeovers between grain types. The operator can override the saved settings at any time during harvesting and adjust them in accordance with the prevailing conditions. Further advantages of CEMIS 700 include its ability to store jobs and to record fuel consumption separately for road and field operation as well as in litres per hour and litres per hectare. As CEMIS 700 is a fully-fledged ISOBUS terminal, it can also be used for other tasks with tractors and implements outside the combine harvesting season.

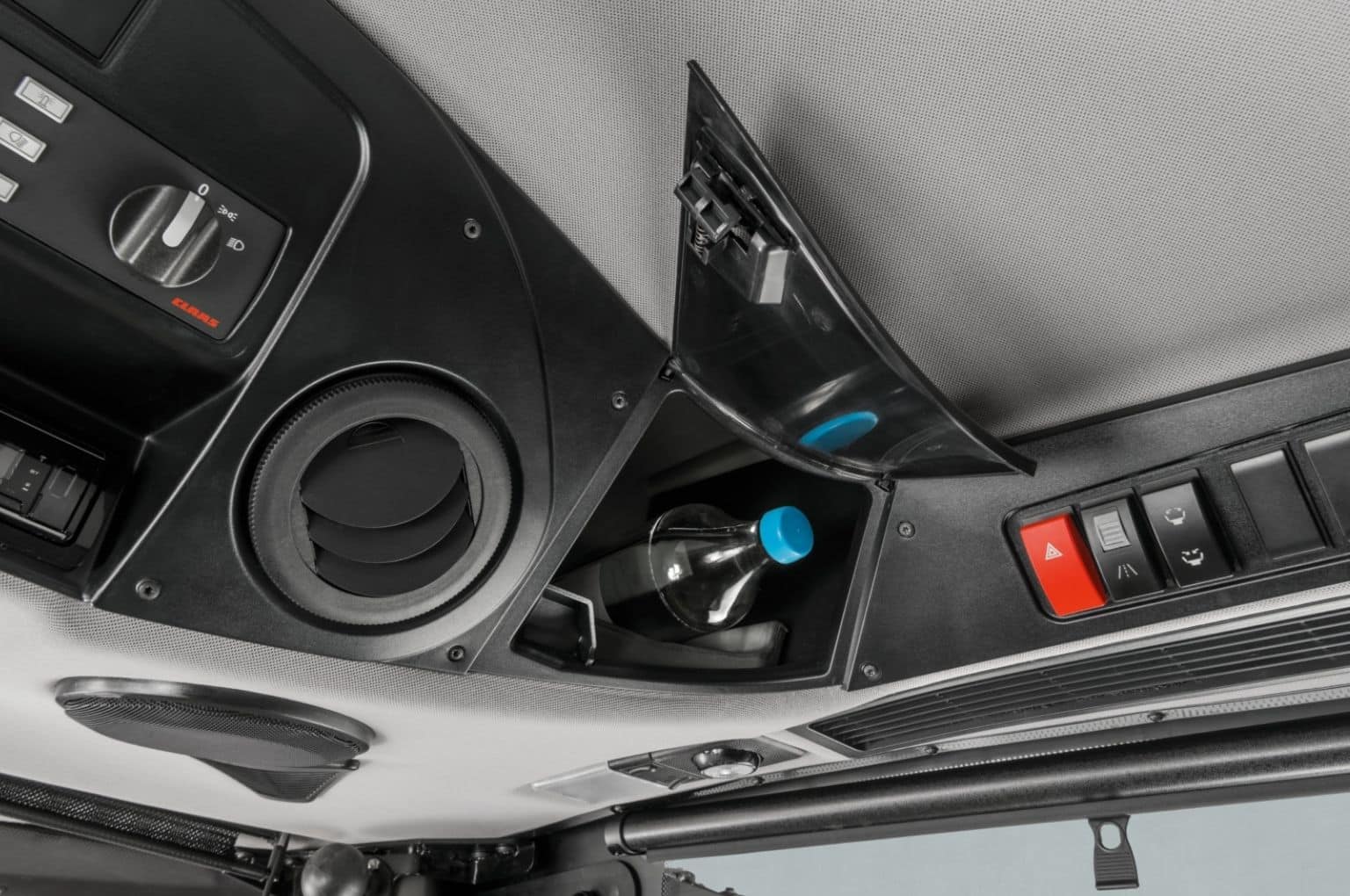

All EVION models are equipped as standard with automatic climate control and a camera while footrests on the steering column are available as an option – as is a 30-litre cool box under the instructor’s seat. Other optional items include an air-suspended comfort seat, electrically adjustable rear-view mirrors and a second camera.

The cab also provides numerous storage options as well as one USB port and two USB-C ports which can be used to charge smartphones, tablets and other devices.

Although the EVION models are already equipped as standard with a comprehensive LED lighting package, the list of options provides for a total of up to 17 LED work lights ex factory – and extends to interior lighting for the grain tank and maintenance lighting under the side panels.

Cutterbars up to 6.80 m working width

With its Claas universal feeder housing and multicoupler, the EVION is able to accept the front attachments already used with the TRION and LEXION models: grain cutterbars up to a working width of 6.80 m and maize pickers for up to 6 rows. On CLASSIC versions, the front attachment is driven by a single belt while MAXI versions have two. The MAXI version of the EVION is therefore recommended for grain maize harvesting. The TREND equipment package includes CONTOUR ground contour adaptation as standard. This automatically adjusts the front attachment to ground undulations parallel to the direction of travel. EVION models in BUSINESS configuration are equipped with the AUTO CONTOUR system as standard (option on CLASSIC version) which is programmed via CEMIS 700 for precise adjustment of the cutterbar table to cope with ground undulations both parallel and transverse to the direction of travel. The new EVION is built in the Claas works in Gaomi, China.

EVION at a glance

- Three models with engine outputs of 204 to 258 hp

- CLASSIC base version primarily for grain threshing

- MAXI version for better performance in corn and beans

- TREND and BUSINESS equipment packages with a wide range of additional features

- Use of proven components from TRION and LEXION

- Single-drum threshing unit with large, 600 mm threshing drum and a feeder housing width of 1,420 mm

- MULTICROP threshing concave with 0.95 m2 threshing concave area

- Five long straw walkers with centre risers optimised to support crop flow and a separation area of 6.25 m2

- Optional active crop flow monitoring with CEMOS AUTO CROP FLOW

- High-performance cleaning with 4.80 m2 sieve area; loss measurement and electric adjustment of sieve as standard

- Grain tank capacity of up to 8,000 l and fast offloading at 90 l/s

- High-performance grain elevator operating at 34 l/s

- Straw chopper with 52 or 72 knives; optionally with chaff spreader

- High-torque at low revs from Cummins six-cylinder engine

- DYNAMIC POWER engine management for fuel saving of up to 10 percent

- 3-speed hydrostatic drive

- Soil protection with tyre diameters up to 1.85 m at front and a maximum of 1.50 m at rear

- Spacious cab with automatic climate control, air-suspended seat and ergonomic control armrest including CEMIS 700 and CMOTION

- LED lighting package for perfect evening/night illumination of work area

- CEMIS 700 with job management and differentiated logging of fuel consumption

- Simplified maintenance enabled by three compressor connection points, LED maintenance lighting and excellent accessibility all round