With the launch of 20 new combine harvesters in the Trion model series, Claas has renewed almost its entire combine harvester range in the space of just two years. The Trion model series comprises not only 5 and 6-walker machines, but also hybrid combine harvesters with single or twin rotors. Several “Terra Trac” and “Montana” versions are also available. True to the Trion “Fits your farm” motto, the resulting line-up of machines offers a choice of variants and features. The Trion fills in the segment between the smaller “Tucano” and big “Lexion” series. Also it has a good deal of overlap with those series.

Three model series

The Trion range comprises three model series with straw-walker and hybrid combine harvesters and two threshing channel widths:

- Trion 500 with 5-walker APS walker threshing system; 1,420 mm channel width

- Trion 600 with 6-walker APS walker threshing system; 1,700 mm channel width

- Trion 700 with APS hybrid threshing system (Trion 710 – 730 with Roto Plus single rotor, Trion 750 with Roto Plus twin rotor); 1,420 mm channel width

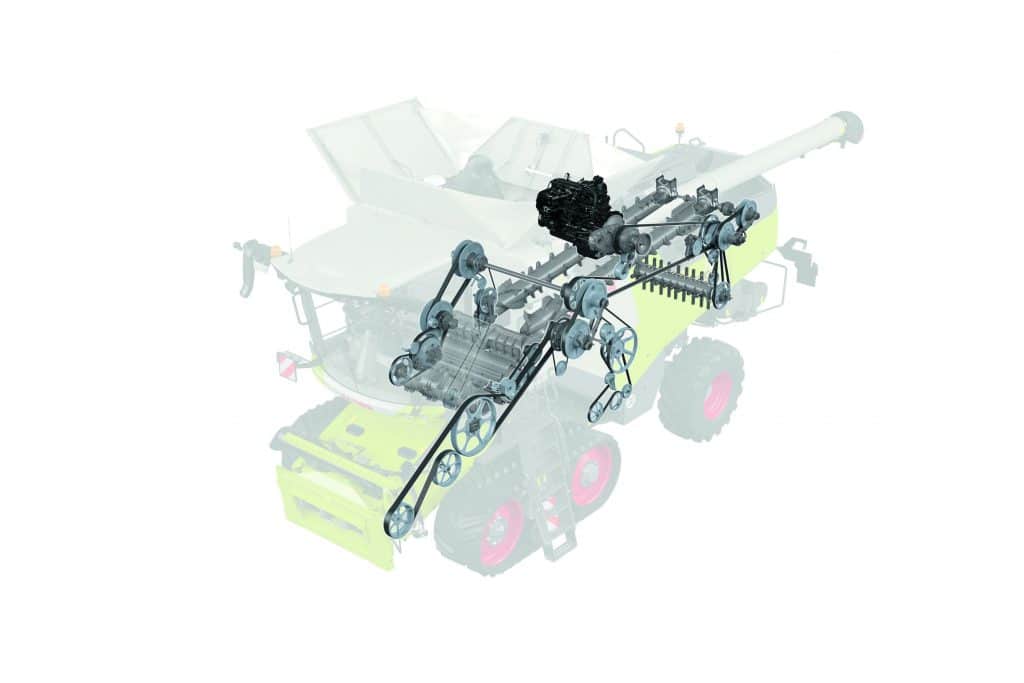

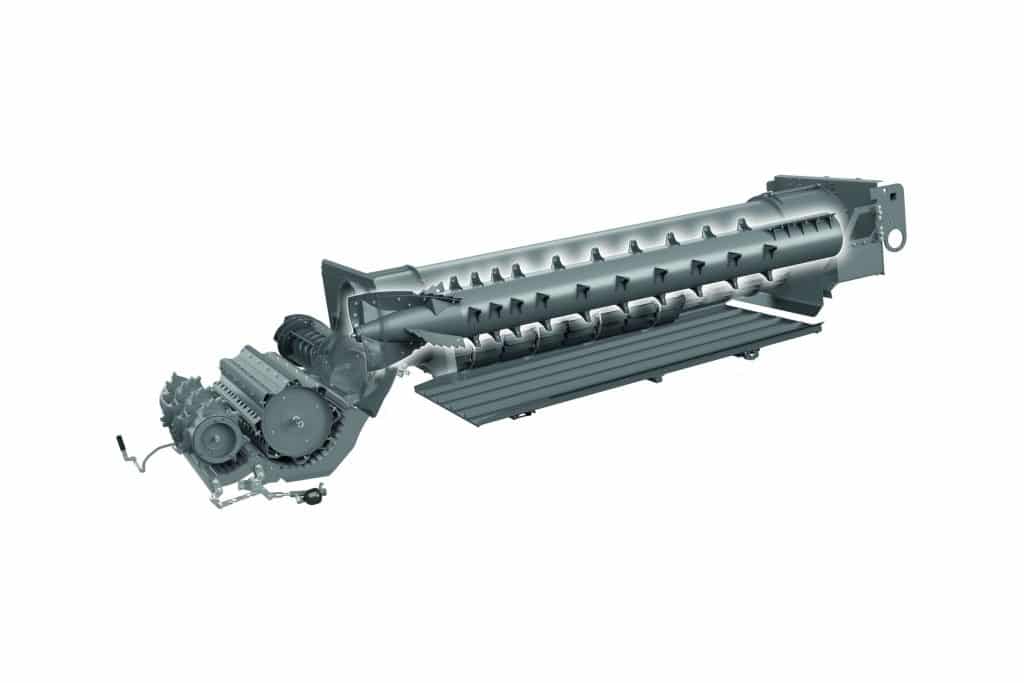

Primary separation in all Trion models is performed by the APS threshing unit with an accelerator drum (450 mm diameter) and a large threshing drum (600 mm diameter) which provides a consistent, high crop flow and allows sustained operation throughout long working days. Some 90 percent of the grains are gently threshed out of the crop in this initial stage. The speeds of all three drums can be adjusted synchronously from the cab via “Cebis”. “Cebis” is also used for the parallel and synchronous adjustment of the preconcave and threshing concave. Hydraulic overload protection allows operation right up to the performance limit, prevents blockages and also provides protection against damage from foreign objects. If necessary, the three concave segments of the “Multicrop” preconcave, which is designed for many threshable crops and threshing conditions, can simply be replaced through the stone trap. The main concave can be equipped with various concave segments, as required, with one concave segment designed as an easily swappable unit.

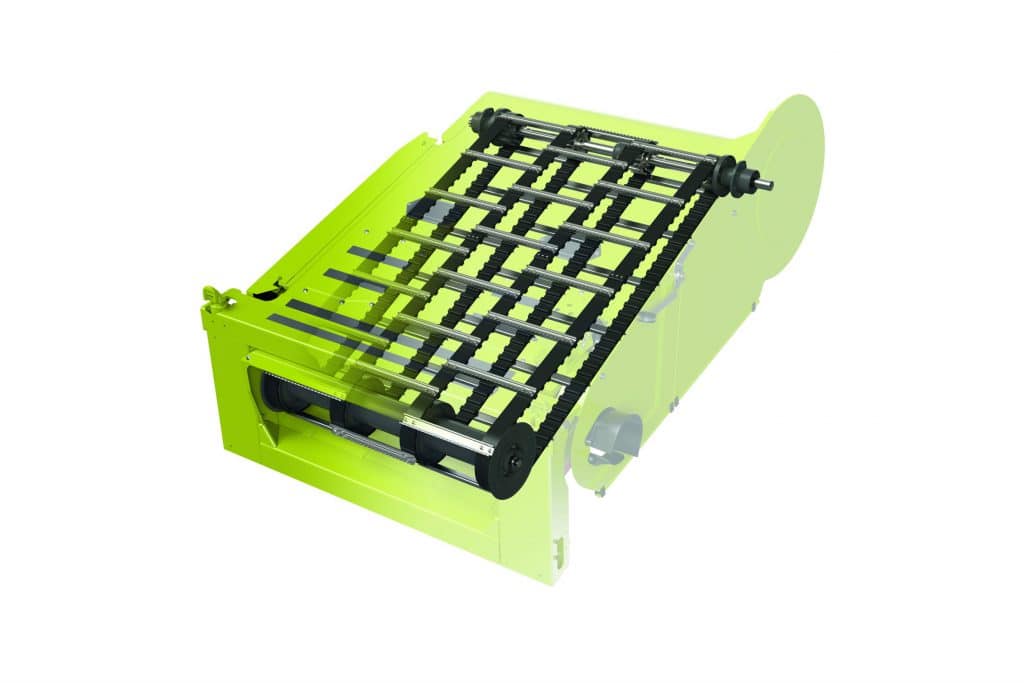

Secondary separation in the Trion 500 and Trion 600 is performed by five or six straw walkers with respective separation areas of 7.48 and 6.25 m2. These models are equipped as standard with the “Multifinger Separation System” (MSS) which fluffs the straw mass evenly, thereby increasing the separation performance significantly, especially when dealing with a high level of straw moisture or volunteers.

Secondary separation in both the Trion 720 and Trion 730 is handled by a single rotor. By contrast, the flagship of the model series, the Trion 750, uses twin rotors for secondary separation. In all Trion models with “APS Hybrid” and “Roto Plus”, the speed of the rotors can be varied from the cab infinitely and independently of the speed of the APS threshing unit. Hydraulic rotor flap adjustment (Trion 720/730: manual adjustment available as an option) makes it possible to close up to four rotor segments, thereby reducing the load on the sieve pan when dealing with dry straw.

12,000 l grain tank with 130 l/s unloading

The grain tank sizes of 8,000, 9,000, 10,500, 11,000 or 12,000 liters vary in accordance with the model and version. Unloading rates range from 90 to 130 l/s. The large 105-degree pivot angle of the unloading tube allows the operator to have an excellent view of the spout during unloading. Available as an option, the “Profi Cam” provides a direct, wide-angle view into the trailer or body of the transport vehicle and so enables the operator to manage the unloading process with even greater anticipation and accuracy. An optional pivoting spout which can be adjusted via the “Cmotion” multifunction control lever makes extremely precise unloading possible, even while on the move.

New Cummins engines

All model series are powered by Cummins six-cylinder engines: the Trion 500 series as well as the 640 have the Cummins B6.7 unit which meets the Stage V standard and has a displacement of 6.7 l, while the Trion 650, 660 and 700 series are powered by the Cummins L9, a Stage V unit with a displacement of 8.9 l. The rated engine speed of the common-rail power plants is just 1,900 rpm, with road travel at a quiet and fuel-saving 1,650 rpm. All engines have the “Dynamic Power” automatic output adjustment system. If the full engine output is not required, when swathing, for example, the engine control unit reduces the output – and therefore the amount of diesel injected – to the required level. This intelligent control system on its own is capable of saving up to 10 percent of fuel costs.

The Trion 500 and 600 have a diesel capacity of 600 and 800 l respectively, while the Trion 700 can be specified with a fuel tank of 800 or 1,000 l. Depending on the model, 80 or 100 l of AdBlue can be carried for the emission control system.

Advanced cab design

Another feature of the Trion model series is the new cab. It offers more space, especially headroom and legroom, and can be equipped with an optional leather seat which swivels 30 degrees to both sides for an optimal seating position at all times. Optional footrests enable a number of relaxed seating positions for the operator. A larger windscreen and side windows with narrower A-pillars provide an excellent view of the front attachment and the surroundings. The 12-inch “Cebis” terminal with a high-resolution, high-contrast HD display ensures legibility under all light conditions and provides three individually adjustable main display areas. “Cemos Dialog” and “Cemos Automatic” are now integrated in Cebis. The terminal can be operated via the touchscreen and rotary push switches. It is also possible to access all the threshing unit and cleaning settings by means of direct access buttons on the right of the control armrest.

The Cebis terminal and armrest can be adjusted independently of each other to provide an optimal ergonomic response to the operator’s needs. And with the “Cmotion” control lever, which is available as an alternative to the standard ground speed control lever, the operator always has the key functions – including up to seven individually programmable favourite settings – at their fingertips for a rapid response.

A 30-litre cool box, an optional 360-degree LED lighting package and a 360-degree windscreen wiper complete the comprehensive package of features.

Four steering systems and new Cemis 1200

Customers have a choice of four automatic steering systems. “Laser Pilot” steers by using the left-hand edge of the crop as its point of reference. “Field Scanner” is fitted on the roof of the cab and steers the Trion by optically sensing the edges of the crop (left and right possible) and tramlines. During grain maize harvesting, the Trion is steered by the “Auto Pilot” on the “Corio” and “Corio Conspeed” pickers.

The fourth option is “GPS Pilot” with satellite-based navigation. The new “Cemis 1200” terminal with a 12-inch screen is available for this function. It offers 2D and 3D views, online task management

and documentation with data export via “Telematics” or USB stick, real-time yield mapping and yield data displays.

Six Montana and Terra Trac versions

The chassis of the Trion “Montana” machines is able to compensate for side slopes of up to 18 percent and longitudinal slopes of up to 6 percent. In addition, the Montana machines have “Power Trac” all-wheel drive, “Auto Slope” to manage cleaning performance on slopes and an optional electrically engageable differential lock for the front wheels. Common to all chassis types are two drive ranges for each of the two speeds.

Terra Trac crawler tracks in three track widths from 635 mm to 890 mm are available for six models. All Terra Trac models, like the wheeled machines, are capable of road travel at up to 30 km/h.