Apex.AI, a company developing safety-certified software for mobility and autonomous applications, is adding new capabilities to the Fendt Xaver concept vehicle, an autonomous farming robot, by incorporating Apex.OS, an easy-to-use software development kit (SDK).

Apex.AI has enabled AGCO’s engineering team to integrate several autonomous driving components into the Fendt Xaver in a tight timeframe, including lidar object detection, collision checking and planning, using the framework and developer tools that come with Apex.OS.

This technical partnership expands an existing relationship between the two companies. In December 2021, AGCO announced a strategic investment in Apex.AI.

“Apex.OS is a foundational software framework and development kit for rapidly developing advanced autonomous capabilities,” said Christian Kelber, Director, Engineering, AGCO.

“The technology has helped AGCO shorten R&D timelines of our smart agricultural solutions and for the future of highly automated robots. Coming from the automotive industry, Apex.AI enables us to implement safety-critical applications from autonomous driving that can be deployed across our range of solutions globally.”

Centimeter precision

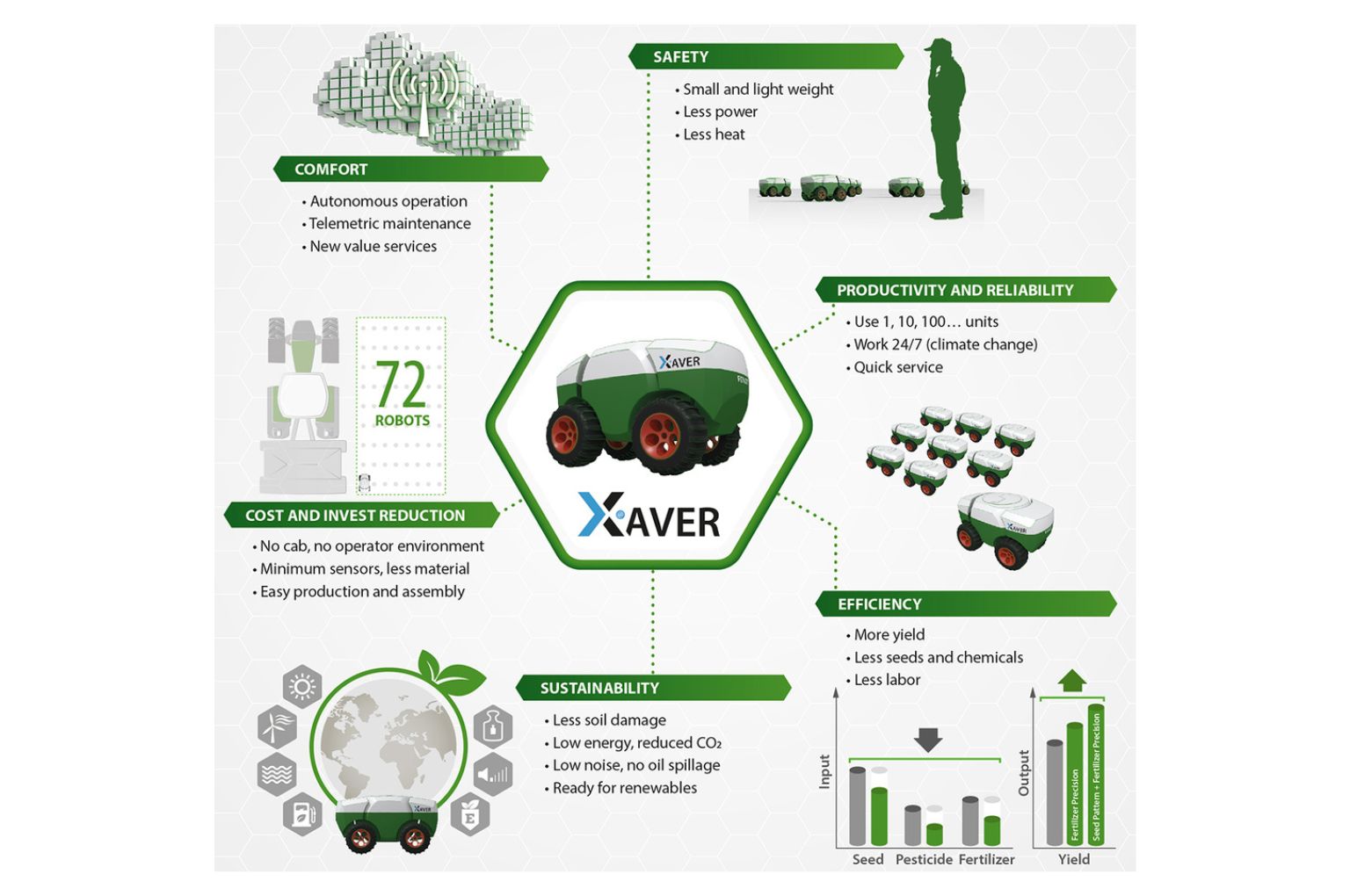

“The award-winning autonomous robot concept Fendt Xaver, developed by Fendt as part of a research project, plants seeds on farms 24 hours a day with centimeter precision thanks to the Apex.OS software”, says Jan Becker Co-Founder and CEO of Apex.AI.

“Fendt Xaver uses 90% less energy than conventional machines because of its lightweight electric design, which produces zero emissions.

At a high level, Fendt Xaver robots are used as a cloud-connected fleet that is controlled through an app. The fleet provides real-time data from each unit, including its location, status, and diagnostics.

As a team, the Fendt Xaver robots collaborate in a completely autonomous and efficient way and with high precision to reliably accomplish field tasks, such as planting seeds, around the clock.

From the Apex.AI perspective, our objective in working with AGCO is to demonstrate that there’s a viable future in autonomous farming technology, particularly as it relates to our automotive safety-certified products.”

Automotive industry standards

AGCO has leveraged Apex.OS to develop a software stack for Xaver based on automotive industry standards, extending its real-time autonomous functions. A cloud-connected fleet of Fendt Xaver robots is controlled through an app and provides real-time data from each unit, including its location, status, and diagnostics.

“We are leveraging our success in the automotive and autonomous driving industry and applying it to areas that have similar functional safety needs such as agricultural, industrial, mining and construction,” Jan Becker continues. “Apex.OS allows the software architecture to be modular, scalable and safe, enabling customers to transition their R&D projects to commercial-ready products in record time.

There is an increasing trend of autonomy in agriculture, and designing and deploying a safe autonomous system is a complex and time-consuming task. Apex.AI is helping its agriculture, automotive and industrial customers extract the complexity of software-defined vehicles and machines with Apex.OS, which achieved the highest level of automotive software safety ISO 26262 ASIL-D last year. By bridging the gap between R&D and production quality solutions, customers using Apex.OS can overcome real-time and reliability software challenges at a record pace.

Apex.AI developed the foundational software framework and development kit that enables AGCO to rapidly develop its advanced autonomous capabilities, including the Fendt Xaver. Manufacturing companies like AGCO are experts in hardware, not software. Apex.AI’s expertise is building safety certified software that removes the foundational complexities of building a software solution from scratch. The engineering team is therefore freed up to focus on the important aspects of building the product without having to worry about the software”, Jan Becker concludes.