Although only a little more than three years have passed since Claas began manufacturing the Jaguar Terra Trac, the company is already celebrating the production of the 100th model. The landmark machine rolled off the line in Harsewinkel Germany, on 4th February and will be delivered to the main market US.

The end of 2018 saw Claas implement the successful Terra Trac crawler track technology in the Jaguar forage harvester. Optimised for the requirements of this machine segment with special features such as the headland protection system, the Jaguar Terra Trac made it possible for the range of applications of a forage harvester equipped with crawler tracks – which reduce both soil compaction and rut formation – to be extended to grassland harvesting for the first time, thereby enabling optimal protection of the grass cover. “Helmut Claas himself was behind the initiative to develop the Terra Trac crawler track units for a wide range of forage harvester applications”, recalls Dominik Grothe, Senior Vice President Forage Harvester. “The aim was to offer our customers a machine that was not only able to deliver high traction and reduced soil compaction for maize harvesting in difficult field conditions, but could also be used for grassland harvesting as effectively as a traditional wheeled machine. It’s interesting to note that the positive side-effects, such as smooth running characteristics and resistance to drifting on side slopes, are regarded by many farmers and contractors as equally decisive factors.”

Wide range of customer benefits

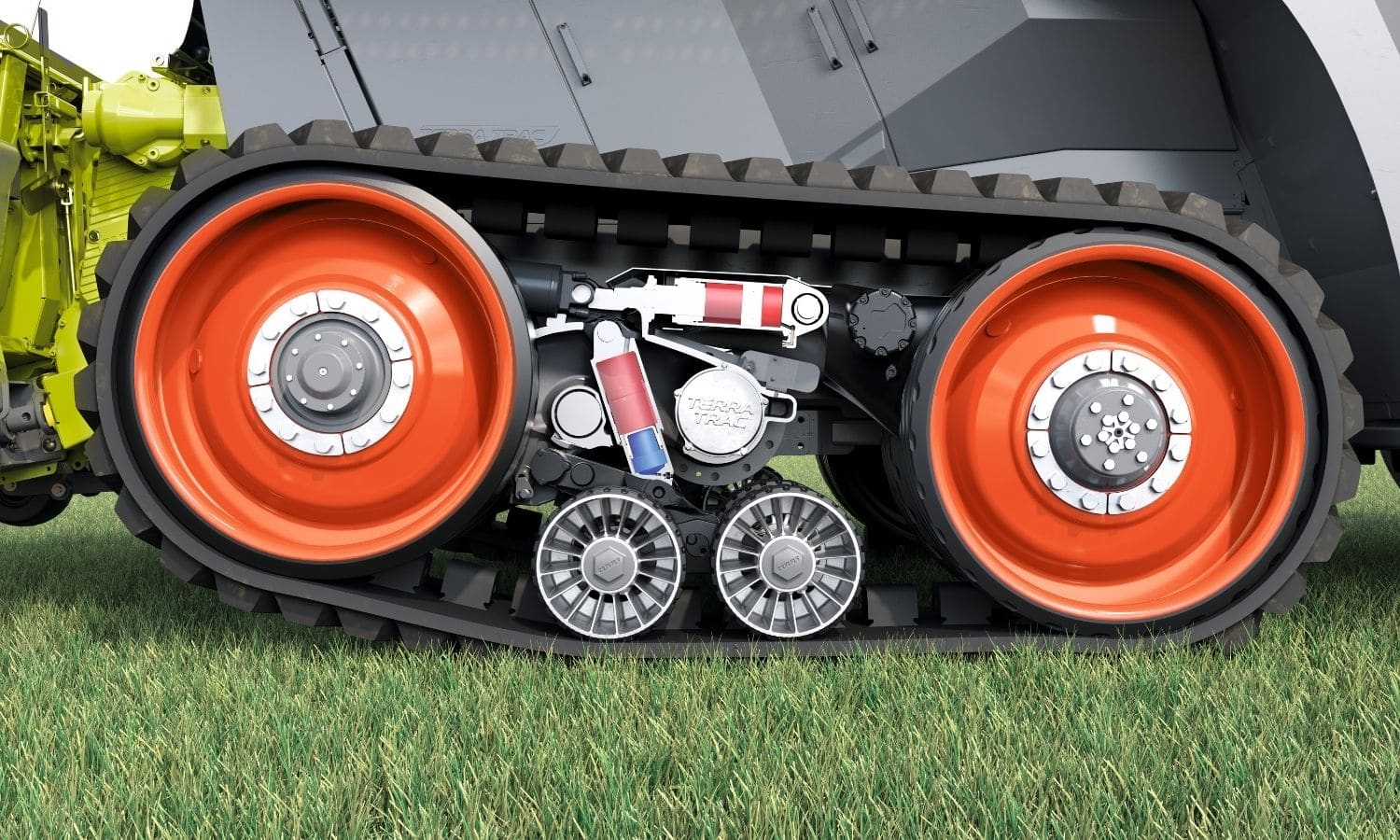

Claas offers the Terra Trac crawler track units for two models – the Jaguar 960 and the Jaguar 990 with respective maximum outputs of 653 and 925 hp. The “headland protection” function, whereby the two central support rollers are extended downwards hydraulically, reduces the length of the contact area significantly so that the tracks have considerably reduced contact with the ground when turning. During the actual harvesting process, the large contact area reduces soil compaction and keeps rut formation to a minimum. When maize is being harvested in extreme conditions, such as may be encountered in northern Germany or Denmark, the crawler tracks keep rut formation down and deliver maximum traction. Equipped with 635 mm wide tracks, the Jaguar has an external width of less than 2.99 m and can therefore run on public roads – ideal when frequent transfers between fields are required.

A compact road travel width is of lesser importance in the US, the largest market for the Jaguar Terra Trac. “For dairies in the eastern part of the US where approximately two-thirds of our imported Jaguar TT are sold, Terra Trac technology is a kind of are insurance policy against mud in corn silage season. But also customers in the south and west harvesting in center pivot irrigated fields appreciate the Terra Trac technology”, says Dominik Grothe. “As a result of the length of the crawler tracks and the wheelbase which is longer than that of the wheeled machine, the Jaguar Terra Trac can’t be matched for the smoothness of its ride when crossing center pivot ruts or flood irrigate ridges.” North America is also the destination of the 100th Jaguar Terra Trac. This machine, with serial number 49900100, will be used initially for technical training during the Jaguar Expert Camp scheduled for April. “Our flagship model, the Jaguar 990 TT, accounts for over 90 percent of the Terra Trac machines”, explains Matt Jaynes, Product Manager Jaguar at Claas of America. “When you’re harvesting small grain forage and silage maize in irrigated fields in the western states, you’re dealing with very high yields which require correspondingly high engine output if you’re going to harvest efficiently. This is why we need the 925 hp maximum output of the JAGUAR 990 here.”