For the first time, Fendt presented implements from the Feucht (Fella) factory at Agritechnica 2015 as part of its own product range. From that time, the machines were mainly green-painted products from the existing range.

Over the past nine years, both the Fendt product range and the production and development location for green forage solutions have been continuously expanded and improved. The rising demand reflects the positive effects of investments in the development of an extensive product range and the expansion of production. Today, Fendt offers mowers, tedders and rakes for the global grassland market – from Europe to Australia and New Zealand.

Range of forage solutions

Developments such as the Streamline cutterbar, the automatic lateral displacement of the Slicer FQ front mower – controlled by data from the rear mower – the speed-dependent control of the contact pressure with the TurboLift cutterbar relief, or the automated conditioner setting for the Fendt Slicer 960 KCB mower combination, was honoured with the Silver DLG Innovation Award.

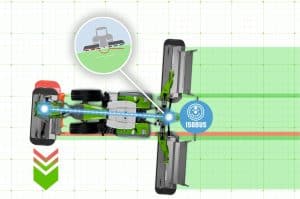

The latest development of the Fendt Former C two-rotor central delivery rake completes the range of smart Fendt Former rakes from two-rotor to four-rotor rakes with ISOBUS functions, such as the in-house development of the flexHigh rake height adjustment included in the Fendt proConnect ISOBUS package.

With its wide variety of machines, Fendt covers the needs of different customer groups. Specially developed compact and lightweight solutions for the Alpine region is part of the product range, as are machines for in-house mechanization. With its range of ISOBUS-compatible grassland solutions, Fendt fulfils the requirements of professional farms and contractors. These include, for example, the Fendt Former 14055 PRO four-rotor rake or the Fendt Slicer 960 KCB rear mower.

Expansion and modernization

New developments of the green forage machines were preceded by numerous conversion and modernization measures. Investments totaling EUR 21.6 million from 2018 onwards are evidence of the location’s significant further development. The groundbreaking ceremony for the new assembly hall for mowers took place in 2018. SAP was implemented in the same year. This allows information from production to be managed more efficiently and orders to be processed more effectively. The Fendt Lotus tedder series was successfully integrated into production at the Feucht location in 2019.

Further investments in 2020 and 2021 improved paint quality, assembly and logistics processes as well as quality control. These were rewarded with ISO certification, among other things. In the years that followed, the logistics at the factory and delivery to dealers were comprehensively reorganized. Today, a new storage concept and the new logistics centre ensure delivery quality of the machines.

The most recent remodeling at the Feucht location included the creation of a new dispatch area with several covered loading ramps, which now ensures that all machines can be dispatched nationally and internationally regardless of production times.