Drawing on experience and user feedback, Kuhn renewed its series belt mergers. Concept and strengths with this new generation Merge Maxx 102 was kept. The new range counts five models, offering versatility in terms of fodder delivery.

The front-mounted 442F model, with a 3-meter pickup width, moves fodder before the tractor wheels pass over it. Its double conveyor system allows for bilateral delivery with the same amount of fodder on each side.

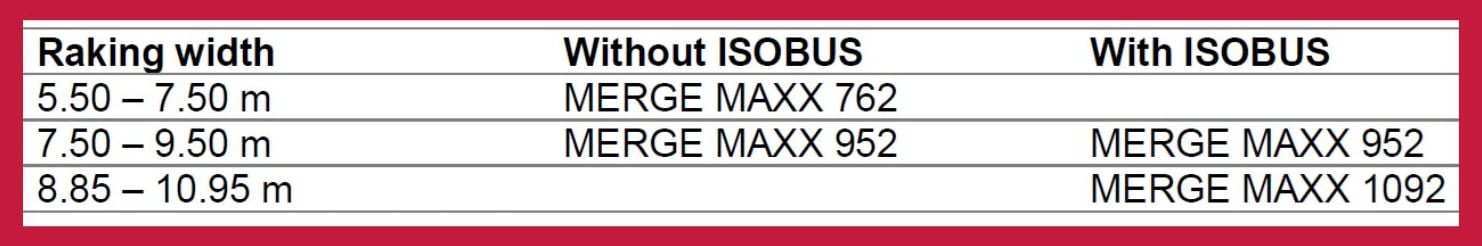

The four trailed models offer working widths from 5.50 to 10.95 meters. The intermediate model, the 952, is available in two versions: standard, without ISOBUS functionality, and an ISOBUS version for greater comfort and functionality.

For both models, all machine settings can be adjusted from the cab using the ISOBUS.

Thanks to the tractor’s onboard ISOBUS terminals ISOBUS terminals, numerous functions can be controlled, such as windrow delivery, working height, unit suspension, Windguard volute position, and more.

The setting menus and the work screen have been designed to be intuitive and easy to understand for users. This makes it easier to learn and manage the various controls.

The operator can monitor the indicators on the work screen. The speed and ground pressure of the conveyors and pick-ups are displayed, allowing for rapid adaptation to working conditions and optimization of machine performance.

Designed to handle different types of fodder, terrain and harvesting methods, the ISOBUS models can be adapted quickly and easily via the in-cab ISOBUS terminal:

Adjustment of the Windguard roller and transfer plate:

Necessary for perfect and regular transfer of fodder from the pick-up to the conveyor belt, the angle and position relative to the pick-up are adjusted continuously from the terminal.

Ground pressure adjustment with 5 settings:

From one day to the next, from one plot to the next, the soil structure changes. This setting offers the user different possibilities to work optimally without damaging the topsoil.

Adjusting pick-up and belt speed:

Depending on the quantities and volumes of fodder, it is important to adjust the rotation speed of the pick-ups and conveyor belts to ensure regular fodder transfer without affecting its quality. These parameters are adjustable from the work screen.

In automatic mode, the rotation speed of the pick-ups and conveyor belts can be adjusted based on the ground speed. Similarly, in the side delivery configuration, the conveyor closest to the windrow and handling the largest load of fodder, can rotate faster than the conveyor furthest from the windrow. This feature prevents the formation of fodder clumps in the machine channel.

Three modes are configurable and can be saved to avoid wasting time during plot changes.

Adjusting the working height:

Pick-up height is a key parameter for maintaining excellent fodder quality without incorporating impurities and stones into the harvested product. It is also a factor influencing tine wear. Adjustment from the in-cab terminal allows the user to easily adapt to working conditions.

“Pick-up without delivery” function:

To avoid the machine having to pass through complex areas, the Merge Maxx 102 incorporates a pick-up function. The latter consists of temporarily stopping the conveyors when collecting the fodder to move it later to a more favourable area.

Built to last

The new mergers benefit from reinforced parts, guaranteeing reliability during the fodder harvesting process. The tubular structure supporting the pickup units are of larger diameter. This increases the machine’s service life.

As the pick-up is the part most exposed to wear and stress, particular attention was paid to this part of the machine. Tests were carried out in real conditions around the world to find the best solution in terms of performance and durability. These criteria are achieved thanks to a range of new features.

The fodder flow, which is particularly important for consistent work, has also been optimized. The tine path and the area between the pick-up and the conveyor belt have been refined to ensure excellent fodder flow and thus a uniform, clump-free windrow.

Finally, the front and rear sealing of the conveyor belts has been redesigned to prevent fodder, soil and impurities entering the machine