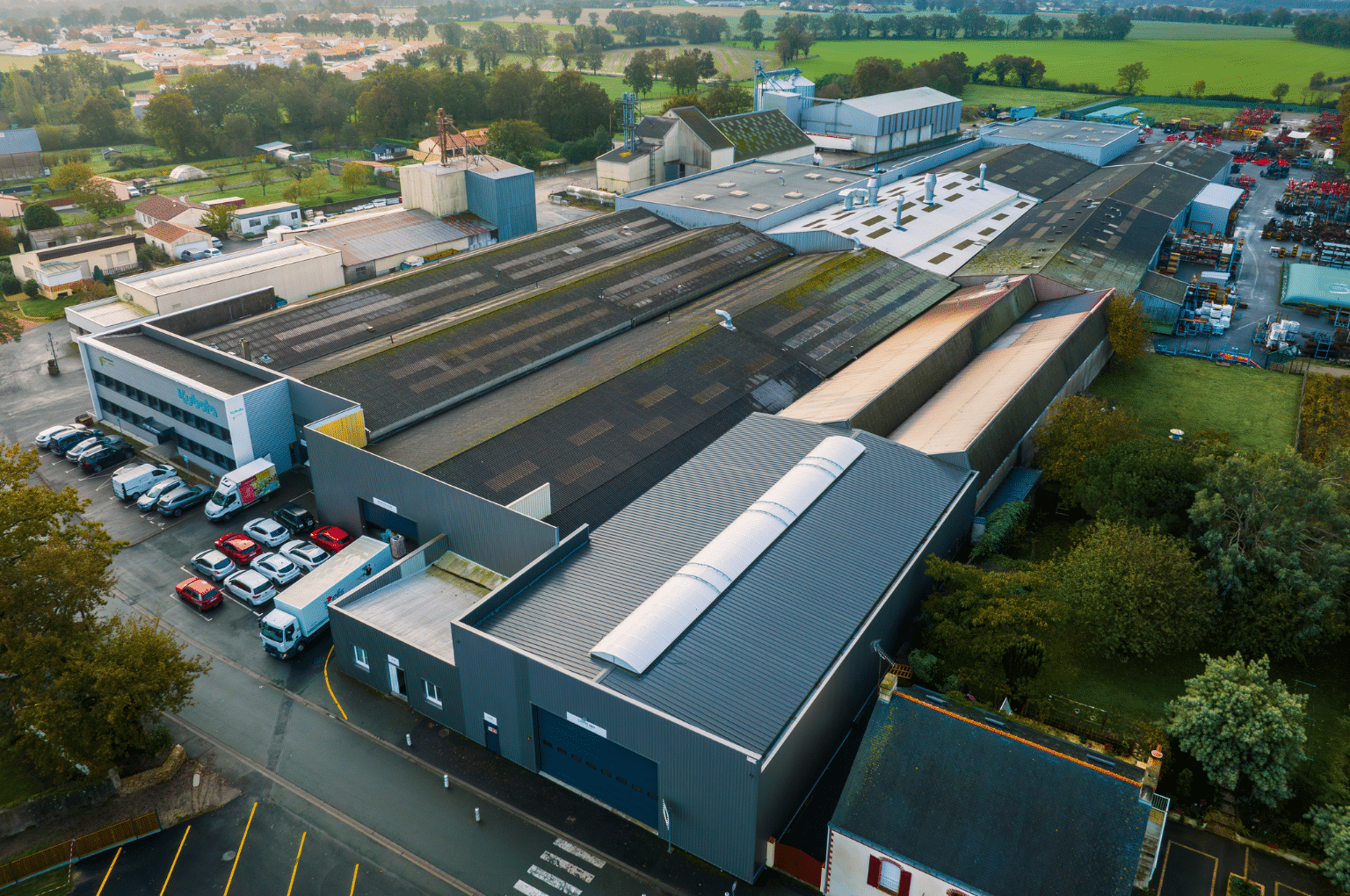

Kverneland Group Les Landes-Genusson (KVG LLG) in France is strengthening its position in cultivation and mechanical weeding solutions. A strategic investment, driven by increased global demand, will double production capacity for both Kubota and Kverneland implements, introduce larger machinery like the XL compact disc harrow, and support the growing need for sustainable mechanical weeding solutions.

“This expansion underscores our commitment to innovation and sustainability,” says Guillaume Hulin, Managing Director, Kverneland Group Les Landes-Genusson. “By increasing capacity and modernizing operations, we’re ensuring KVG LLG continues to provide efficient and environmentally responsible solutions to farmers worldwide.”

KVG LLG’s expansion reflects a strong focus on environmental responsibility. By leveraging various systems, the project emphasizes sustainable practices, energy-efficient processes, and safety standards that align with global environmental goals. The expansion is set to be completed by mid-2026.

Key facts of the expansion

Land acquisition

An additional 17,605 m² of land has been acquired, increasing the total factory area to 5.5 hectares.

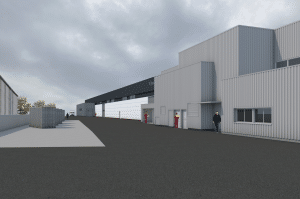

Facility expansion

The building footprint will grow from 13,200 m² to 20,000 m², providing expanded technical centers for welding, painting, assembly, and R&D prototype development. 2 solar power plants will be implemented on the building roof and on car park shed for a total of 770 kWp.

R&D advancements

The R&D prototype workshop will increase from 645 m² to 1,000 m², fostering innovation, supported by new R&D offices.

Modernized equipment

Investments in welding and painting robots, along with automated guided vehicles (AGVs), will streamline operations.

Logistics improvements

Shipment capacity, including container handling, will double, supported by reorganized logistics offices and new storage facilities.

Enhanced traffic flow

A one-way traffic system for trucks will optimize operational efficiency, avoid truck traffic inside the factory and the Les Landes-Genusson center.

Employee amenities

Solar panel parking facilities and state-of-the-art work environment