GRIMME introduces the new generation TOPPA haulm toppers in various working widths. Low power consumption, a redesigned housing and increased suction power, are some of the new features.

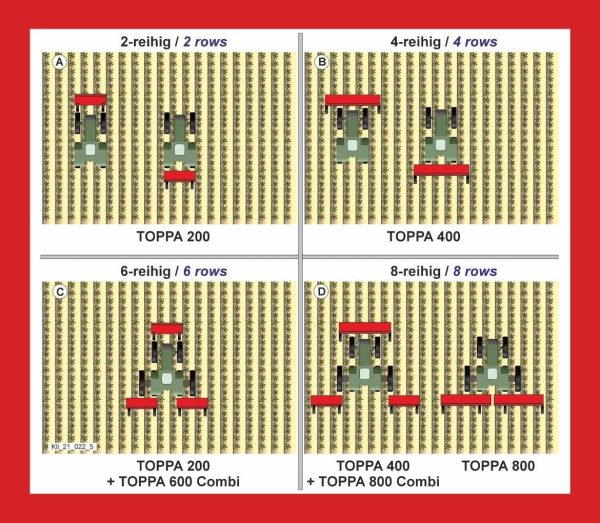

With the TOPPA series, different models are available that enable haulm topping of 2, 4, 6 or 8 rows in front and rear mounting or alternatively in a front-rear machine-combination. GRIMME offers all international, commonly used row widths and track widths, taking into account different flail contours for crop cultivation in ridges or beds.

The new generation of haulm toppers includes five models, which can be used in solo-operation or in different combinations

2- and 4-row in solo-operation

The TOPPA 200 and 400 are 2-row and 4-row haulm toppers, respectively, which are suitable for both front and rear attachment. By optimizing the gearbox position, the angle of the PTO shaft to the tractor has been flattened. This significantly reduces wear on the PTO shafts, especially when lifting the haulm topper at the headland.

The angle of the gearbox can be adjusted on the TOPPA 400. This considerably increases the service life of the drive shaft

The 4-row machine with a row width of 90 cm, is now also equipped with a continuous flail shaft – without any bearing and missing flails in the middle of the shaft. Large maintenance flaps across the entire width of the housing make it easier to clean and change the flails.

6- and 8-row toppers as front-rear combination

The 6-row front-rear combination consists of the TOPPA 200 in the front attachment of the tractor and a TOPPA 600 Combi in the rear. The TOPPA 600 Combi is folded hydraulically so that two rows are folded on either side of the tractor. The machine can be hydraulically folded to a transport width of 3 meters for a fast change from field to field.

Combination of the TOPPA 200 and TOPPA 600 Combi for 6-row haulm topping

For an 8-row front-rear combination, the TOPPA 400 in the front is combined with a TOPPA 800 Combi in the rear. Here, the two booms in the back of the tractor are also folded hydraulically to operate two rows twice. With the TOPPA 400 haulm topper, the road transport width is 3.29 meters with a row width of 4 x 75 cm.

On both the TOPPA 600 Combi and the TOPPA 800 Combi, the two booms can be controlled separately from each other via a hydraulic control box or optionally via ISOBUS with AUX-N assignment. In conjunction with the standard wide-angle PTO shafts, it is therefore possible to lift the haulm toppers independently of each other on wedge-shaped surfaces. The two housings are also pendulum suspended, allowing them to adapt to uneven ground. An optional hydraulic side shift is also available, which can be controlled manually or, in the highest configuration level, can adapt fully automatically to the alignment of the ridges. This is particularly relevant if the number of rows of the planter does not match the number of ridges of the haulm topper.

All three foldable TOPPA models can be parked in a space-saving manner with the help of integrated parking supports when folded

8-row in solo operation

With the TOPPA 800, GRIMME offers an 8-row haulm topper for rear mounting, which can be hydraulically folded to an external width of 3 meters for road transport. The machine is particularly suitable for farms with 8-row planting methods and for tractors without a front PTO shaft.

TOPPA 800 with ridge pressure wheels (so-called RidgeRunner) in working position

Down to the last detail

In the TOPPA series, the typical GRIMME flails are still used, which, adapted to the ridge contour, ensure an even and clean flail pattern. An optimized flail arrangement follows the trend of ever larger ridges. In addition to other flail types, counter-blades can be installed for optimum haulm shredding. These are completely closed and can be positioned closer to the flail shaft in the event of flail wear to ensure consistent work quality. In combination with the new, extended haulm deflector plates, the placement of the potato haulm between the ridges is significantly improved. This has advantages for subsequent chemical siccation, for example, as it ensures good wetting of the stems.

The polyethylene lining on the inside of the housing counteracts soil adhesion, wear and possible stone chipping.

The counter plates are adjustable in the slotted holes

RidgeRunner against green tubers

Optionally, superficial ridge pressing wheels (so-called RidgeRunner) can be selected for each row, which close cracks on the top of the ridges after haulm has been topped. The individual suspension enables optimum adaptation to each row. The extremely low tyre pressure allows the wheels to roll in a targeted manner so that cracks in the ridges are closed. The potatoes can thus be protected from direct sunlight and the risk of green tubers can be reduced. At the same time, fulling ensures that the wheels clean themselves.

The contact pressure of the RidgeRunner can be adjusted individually for each ridge in several stages from 5 kg to 25 kg using a spring

Optimum working light

The haulm topper is guided by the tractor’s three-point hydraulic system and 175 R14 support wheels. The height of the support wheels is adjusted either mechanically via a spindle or hydraulically from the cab. The set working depth can easily be read off and checked at a scale.

Implement road lifting frame

A new “implement road lifting frame” for the 4-row haulm toppers has been developed for road transport with an external width of less than 3 meters. For this purpose, the TOPPA 400 has an additional three-point linkage on the outer left-hand side of the machine-frame. By attaching to the lateral road lifting frame, the topper can be picked up in transport position within a few minutes and can thus be moved at unlimited transport speed.

Compared to previously common systems, neither a drawbar nor the inconvenient repositioning of the support wheels is necessary

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)