Krone and Lemken together, in collaboration with software specialist Lacos, are offering a system for fully automated field work for the self-propelled mower conditioner BiG M and the autonomous process unit (VTE). Innovative tyre track planning not only ensures efficient mowing, but also selectively protects against wildlife mishaps.

Krone and Lemken combine their commitment to achieve the highest possible acreage output and ideal forage quality in mowing with the best possible protection for wildlife. The basis for this is the tyre track planning technology provided by the manufacturers for the BiG M mower conditioner and the autonomous process unit (VTE). This takes into account the natural escape directions of wildlife to prevent accidents from occurring during mowing work. The calculated driving strategies makes it possible for wild animals to follow their natural instincts always to escape from the crop in the direction of quiet areas such as adjacent woods. If there are several potential escape directions, a time-efficient variant is selected as the processing direction to be able to work the field as quickly as possible after measures have previously been taken to protect wildlife such as walking through the field or searching for wildlife with a drone or thermal imaging camera. After the escape direction has been determined, the tyre tracks are created automatically for the relevant machine.

Optimum driving strategy

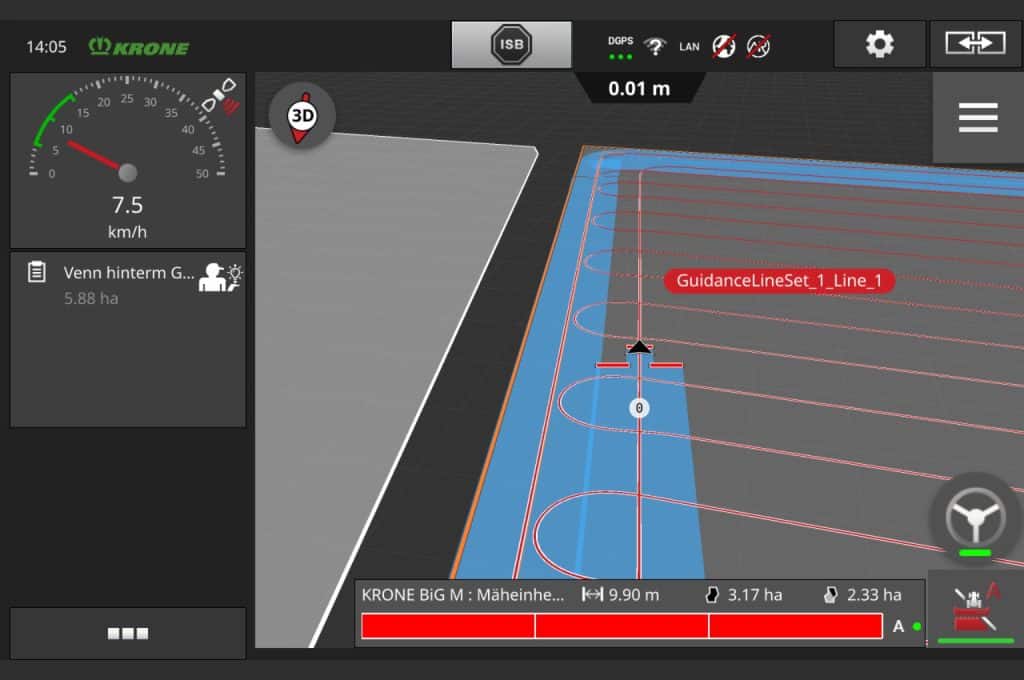

For the autonomous VTE, an endless tyre track is created on a computer in the office and transferred wirelessly to the machine. The planning of the endless tyre track for the BiG M self-propelled machine can also be done directly on the machine. After the system is activated, the mower conditioner equipped with the GPS Guidance steering system is responsible for working the field fully automatically. The BiG M is also able to turn automatically at the headland. The driver is relieved of tasks to a maximum extent and is able to concentrate fully on monitoring the process and the surrounding area. The tyre tracks for working the headland are planned for each specific process and machine while mowing by working the headland first, except for the escape side for wildlife, and then the inside of the field. When working the soil with the autonomous VTE, on the other hand, the inside of the field is processed first and then the headland.

Fully automated field work ensures efficient mowing with regard for wildlife by means of optimum tyre track planning for the BiG M mower conditioner as well as the autonomous VTE. This reduces impurities in the forage to a minimum and reduces stress on the ground caused by double processing. Other positive effects include higher acreage output and lower fuel requirement.