Modern telemetry tools make it possible to gather standard geolocation information, monitor working hours etc. However, they also allow users to monitor the functional data provided by the machine’s CAN BUS. Kuhn is installing this technology named Kuhn Connect, as standard across its entire range of self-propelled mixers with specific interfaces and indicators developed for the use of these farming machines.

What does Kuhn Connect mean in practice? Since the beginning of 2022, all Kuhn self-propelled mixers sold in France come with the Kuhn Connect system as standard. When getting started with their new mixer, the user registers the machine on their MyKUHN personal space using the serial number.

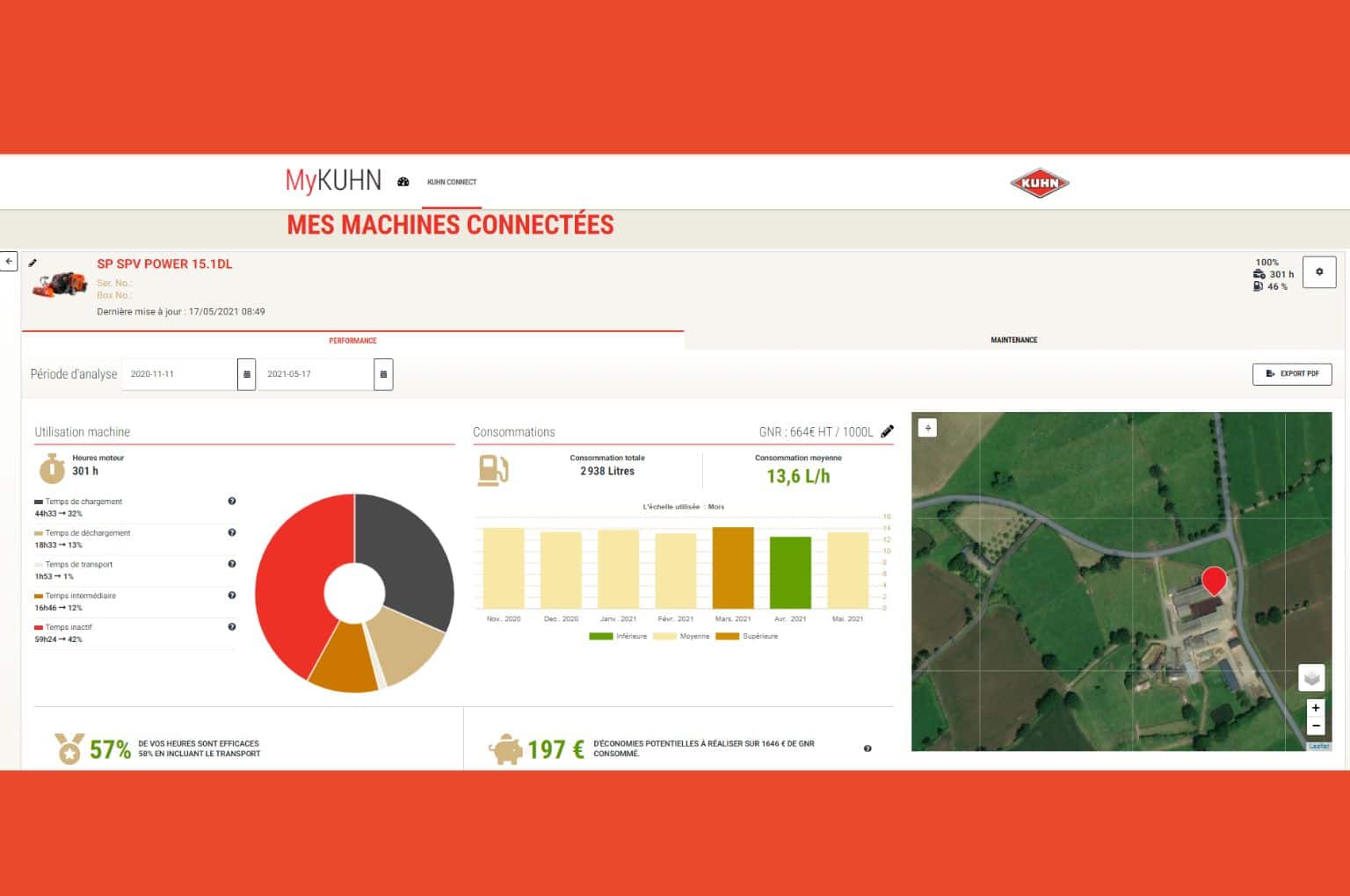

This allows them to access a dashboard display featuring all of the key information relating to their machine. As soon as the mixer is put to use on the farm, the connected module sends back a continuous feed of information. These signals are analysed and translated into indicators, displayed on the farmer’s MyKUHN dashboard.

Going above and beyond the data collected by classic telemetry systems, Kuhn Connect translates these data into pertinent indicators in order to enhance the operational efficiency and functionality of self-propelled mixers for farmers. All of these indicators can be filtered to show results for specific time periods, allowing for more fine-grained analysis:

• A breakdown of the time the machine has spent performing its different functions: loading, unloading, transport, intermediate times and idle time.

• Operational efficiency. This indicator corresponds to the proportion of the total engine running time during which the machine was actually idle. It allows to highlight “down” times generating operating costs.

• Fuel consumption data, highlighting over-consumption risks.

• Potential savings, if users can cut down on the time the machine is “idle.” Fuel purchase cost needs to be entered into the system in advance. The purpose of this data is to help farmers optimise the way they use their machines.

Data are also compared with the average performance of machines of the same model throughout the Kuhn fleet, allowing users to perform their own benchmarking analyses. Kuhn Connect provides easier maintenance and prevention of stoppages!

It also provides farmers with comprehensive information on preventive maintenance via the MyKUHN portal. Users can access their own digital, fully configurable dashboard complete with notification features. When the time comes to carry out crucial maintenance operations, MyKUHN notifies users in advance.

Meanwhile, the farmer’s partner dealerships also have a dashboard in their own Kuhn extranet space which allows them to monitor the performance of the machine and spot the warning signals of potential breakdown risks. The remote diagnostic tools provided to dealerships are a further source of reassurance for farmers, helping to ensure that all technical interventions are fast and effective.