RoboVeg is an autonomous broccoli harvester from the U.K. This ground-breaking harvesting solution, in combination with Robotti autonomous vehicle from Denmark, brings new perspectives for broccoli growers.

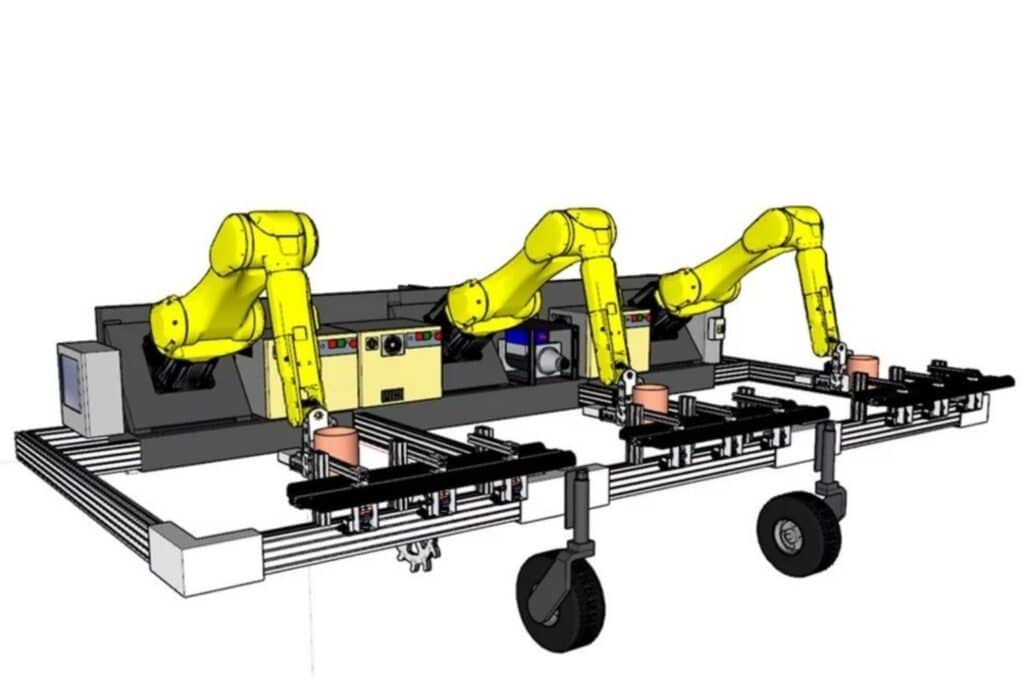

The vision system integrated in the RV range scans the field as the machine moves forward, locating the broccoli heads and accurately sending coordinates to the robots. A new broccoli harvesting cutting tool has been designed specifically for this new harvester, allowing precise length cutting of the broccoli stems. As standard, the robots drop the broccoli heads in boxes located at the end of the harvester, but other collecting solutions could be applied to these harvesters.

Control and Data Analytics

The grower can be specific in terms of cutting instructions. The size range can be determined to within a few millimeters. As RoboVeg collects and communicates data in real time as it traverses the fields, both the operator and farm office staff will be able to keep abreast of progress against targets as well as make commercially advantageous decisions and assessments on the spot.

RoboVeg has the potential to offer yield-mapping functions in real-time and also to allow access to historical data and maps. An electric generator, either hydraulic or fuelled, supplies the energy needed to power the RV.

A low loader trailer can be provided as an optional extra for easy transportation to/from the field. Maintenance contracts can also be provided to ensure the ongoing good condition of the RV.

Together these technologies offer farmers a possibility to harvest around the clock, with a capacity of more than 2400 heads of broccoli per hour, without any human driver or operator.

Developed over the last decade, RoboVeg is believed to be an advanced selective, automated broccoli harvesting solution, with potential to cover a wide range of vegetable harvesting.

With significant benefits to broccoli growers, RoboVeg will reduce harvesting labour costs, improve production control and give greater management information.