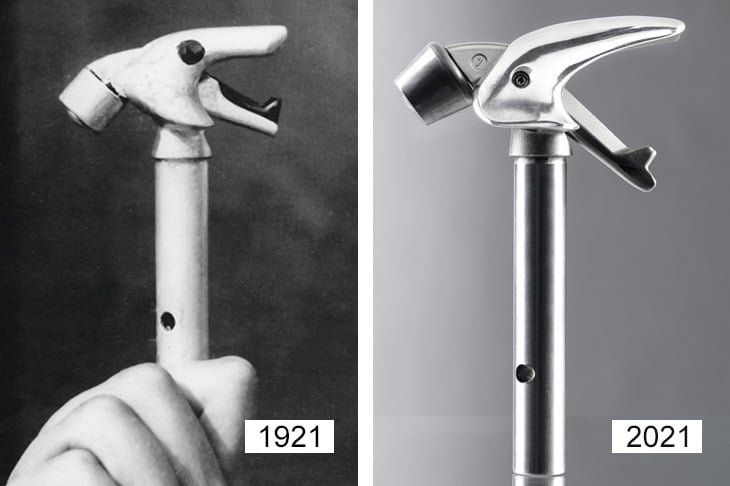

Claas filed its first patent exactly 100 years ago: the knotting device for the straw binder produced at that time. This device laid the foundations for a global success story in baling technology.

The knotter is the core component of square and big balers and its basic mechanical principle has remained virtually unchanged for decades – in both the single and the double knotter. In 1923 Claas developed the groundbreaking ‘knotter billhook with floating upper jaw’ (Patent No. 414212), which defines baling technology to this day and served as the Claas company logo for many decades.

Just two years before, Claas filed their very first patent for a knotting device they invented for use on straw binders. The straw binder was the first product made by the family company founded in 1913, followed by the patented Claas straw baler. In those days both machines were designed to be used in combination with threshing machines. Then in 1934 the Claas pick-up baler revolutionised European straw and hay harvesting by doing the whole job in a single mechanical operation – picking up the crop, pressing it into compact bales and loading it onto the wagon.

Further milestones in the knotter’s history include the 1953 HD high-density pick-up baler, the 1967 “Markant” sliding ram baler and last but not least, the “Quadrant” launched in 1988 – which has clocked up more than 5,500 sales in Germany alone; the major share of the domestic square baler market. Quadrant square balers now operate all around the world – some under very challenging conditions, such as baling sugarcane straw in Thailand and North Africa or maize straw in Europe, China and North America. Starting with the straw binder and moving on to the “Markant” and “Maximum” high-density baler right up to the present-day Quadrant, Claas has produced well over one million knotters to date.

In-house knotter expertise

Today, 100 years after the first patent was filed, Claas still develops and manufactures its knotters entirely in-house as a core business. And CLAAS still swears by the single or loop knot due to its reliability, simplicity and the fact that it produces no twine waste. The most recent major development occurred in 2015, when the knotter bill hook and twine retaining plate were redesigned to facilitate the use of thicker, stronger twines and further improve the reliability of the knotting process. At the same time, Claas introduced Automatic Pressure Control (APC). This system uses sensors to continuously monitor the twine tension and automatically control compaction pressure to avoid twine breakage while at the same time maximising bale density.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)