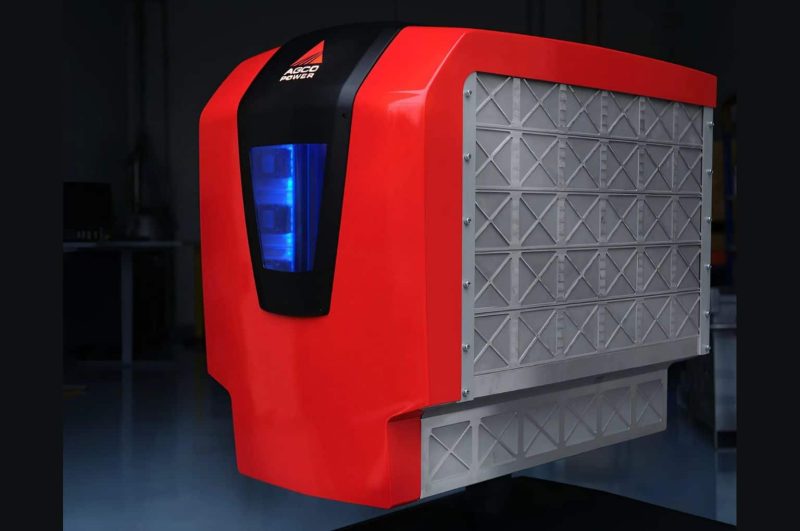

AGCO Power is developing battery technology to enable the electrification of agriculture with cost‑effective, fit‑for‑purpose solutions. In the future battery concept, a total of 1,400 NMC battery cells are used, offering 150 kWh of capacity. It provides space for attaching implements.

“A battery is an expensive component, so we want to design it ourselves. That way we can influence cost and make economically sound choices. More importantly, we can apply our understanding of tractors and agricultural requirements to the battery’s design,” says Juha Heikkilä, Head of Battery Technology R&D at AGCO Power.

The new AGCO Power concept battery is intended as the power source for a small tractor. Safety in extreme operating conditions and packaging within the physical constraints of a tractor are key design starting points.

According to Heikkilä, fully electric tractors are, for now, best suited to lighter agricultural tasks that do not require continuous high power or long uninterrupted operating hours. Electric powertrains offer clear advantages in work machines, such as lower operating costs, an almost maintenance‑free driveline, and the use of new electric implements.

Space is a constrained factor

Requirements in agriculture differ markedly from those in on‑road e‑mobility and many other work machines. A new passenger car can, in practice, be designed around the battery. In buses or trucks, there is often plenty of room available for battery packs.

“A tractor, by contrast, cannot be designed to the battery’s dictates. Space is constrained by factors we cannot change: at the front, room is needed for a loader; at the rear, for a 3‑point hitch or backhoe; and there are standardized mounting points for implements. We must make the most of the space available, even when it’s not optimal for the battery,” Heikkilä explains.

AGCO Power’s concept battery is particularly suited for tasks where zero emissions and quiet operation are an advantage, such as indoor feeding, orchard and vineyard operations, greenhouse cultivation, and municipal street and park maintenance.

“An electric powertrain can also be the rational choice when you look at total cost of ownership over the machine’s life, considering service, energy and lifetime,” Heikkilä notes.

The capacity of AGCO Power’s concept battery is 150 kWh, and it is designed for a tractor with an electric motor in the sub-100 kW power class.

The technical concept selects NMC chemistry for strong energy density and charging performance, combined with cylindrical cells whose long‑term availability can be secured over the machine’s lifecycle.

The battery is specified to operate from −30 °C up to +45 °C. As a result, pre‑heating is required in cold conditions, and both the battery structure and auxiliary systems are engineered for safety in extreme operating environments.

In typical light‑duty work, the battery can power 5–6 hours of operation between charges. On farms, a 50–100 kW charging station is a realistic maximum today, but the chosen chemistry also allows higher charging powers for future needs. A 30‑minute charge brings the battery to an optimal state of charge, and overnight slow charging at lower power is practical.

In heavy, draft‑type work such as ploughing, motor load can average around 80%, which would require returning to charge every couple of hours, a use case where, for now, a fully electric tractor is not the right fit, Heikkilä says.

“Even as charging rates improve, charging‑related interruptions are unacceptable in long, heavy operations. When the weather cooperates, farmers must work efficiently and the tractor must be available. Fully electric tractors do suit agriculture, but for the time being only in certain power and size classes,” Heikkilä reflects.

Benefits from electric powertrains

Electric powertrains in work machines provide clear advantages, including lower operating costs and a driveline that is nearly maintenance‑free. Much of the reduced service need comes from replacing the combustion engine with an electric motor—oil changes, for example, become a thing of the past.

Electric implements are still new, as are autonomous solutions in agriculture, areas where electric tractors are a natural fit. Looking ahead, implements currently driven via mechanical PTO shafts can draw electric power directly from the tractor’s battery, opening new possibilities for implement design and improving usability.

“We don’t yet know all the usability benefits. During visits to AGCO Power’s Linnavuori factory, farmers have even discussed using an electric tractor’s battery as a field‑edge power source for a welding machine, so repairs wouldn’t require moving equipment back within reach of the grid,” Heikkilä concludes.