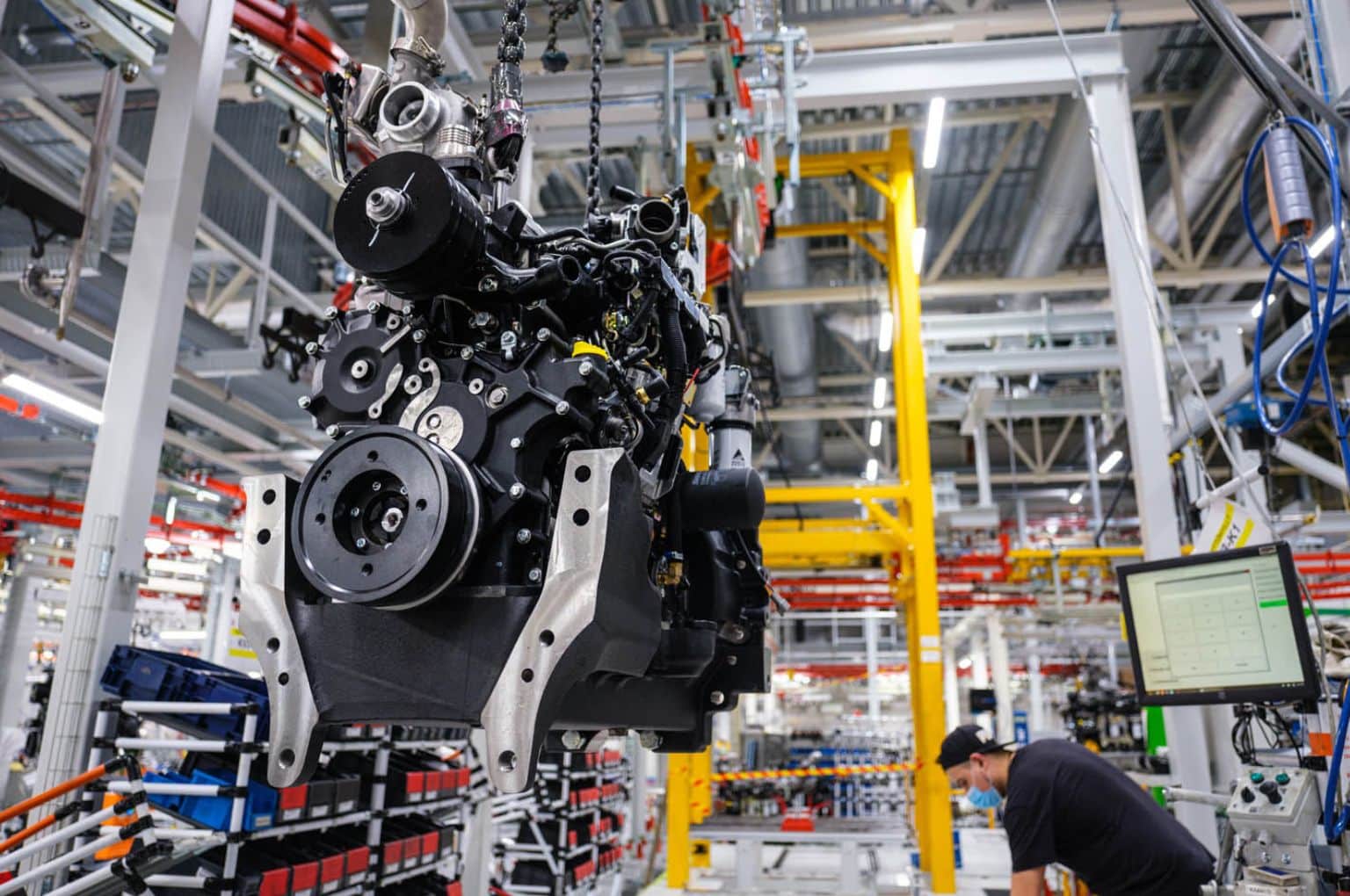

AGCO Power opens new engine production facilities in Linnavuori, Finland, highlighting the importance of the circular economy in modern power generation. The investment, valued at €54 million, is part of AGCO Corporation‘s previous €70 million commitment to the Linnavuori engine plant.

The new facilities include a modern machining hall for manufacturing Continuously Variable Transmission (CVT) components and cylinder heads for AGCO Power’s latest CORE engine. The expanded remanufacturing area increases the plant’s capacity to produce remanufactured engines.

AGCO Power is part of AGCO Corporation. The Linnavuori plant manufactures engines for AGCO’s tractor brands Fendt, Massey Ferguson and Valtra.

“This machining investment strengthens Linnavuori’s role as AGCO’s global center of expertise for engines. We are investing in modern production technology and sustainable solutions that support farmers around the world,” says Kelvin Bennett, Senior Vice President of Engineering at AGCO.

Linnavuori, already Finland’s largest transmission gear manufacturing site by volume, has expanded its capacity with the addition of 5,600 square meters of new production space.

Remanufacturing, circular economy in practice

Stefan Caspari, Senior Vice President of Customer Experience and Business Effectiveness at AGCO, emphasizes that the remanufacturing expansion supports the company’s long-term strategy and Farmer First approach.

“Farmers value total cost of ownership. This expansion enables AGCO to better support them not only with new equipment investments but also with maintaining existing machinery through more cost-effective remanufacturing solutions,” Caspari says.

AGCO Power has been refurbishing engines for over 50 years, with systematic remanufacturing starting in 1990. Today, over 1,000 engines are remanufactured annually, and with the new facilities, the maximum capacity will reach 2,500 engines per year.

“Remanufactured engines extend the lifespan of machines and allow up to 80% of the engine’s mass to be reused, including all cast iron components. This results in a much lower carbon footprint compared to manufacturing a new engine,” explains Jussi Rinne, Director of Quality and Aftermarket.

In addition to remanufactured engines, Linnavuori also produces gas engine blocks and marine engines.

In 2024, AGCO Power also opened a clean energy laboratory in Linnavuori, where future lower carbon engine technologies are researched and tested. The newly completed machining hall and remanufacturing expansion complement the Linnavuori site, strengthening AGCO Power’s position in sustainable power generation solutions.