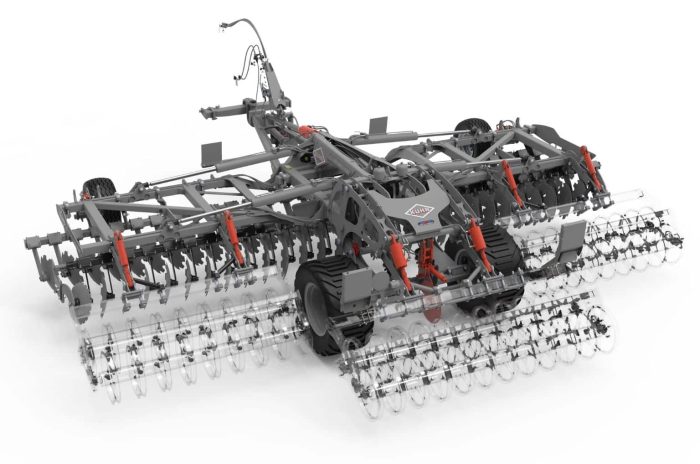

The Optimer 6 and 7.5 meter independent disc cultivators from Kuhn have been upgraded to ISOBUS. Known as Smart Soil Technology (SST), this technology offers users greater working comfort.

Kuhn SST received an “Technological Innovation award” at the recently held EIMA tradeshow in Italy. In addition to controlling all settings from the cab, the SST delivers tangible performance benefits for the user.

“Steady Control Ultimate” enables automatic adjustment of the ground tracking system to ensure an even, uniform working depth across the entire width of the tool. Pressure and position sensors linked to a computer determine the optimum pressure in the extension cylinders for even working depth even on uneven ground and at high working speeds. This improvement eliminates the need for the operator to get out of the tractor to adjust pressures, and improves the accuracy of settings by basing them on actual measured values.

The major innovation of the SST is the “Auto-Line” function, which continuously corrects the machine’s alignment so that it always works in line behind the tractor, despite slopes, changes in working depth or soil type. To do this, the machine is completely autonomous thanks to a coulter that constantly measures the position of the tool in relation to the forward movement. Depending on the data sent back by the sensor on the coulter, a computer will correct the machine’s alignment at the level of the gauge wheels and roller to balance the lateral forces on the front and rear discs.

The task controller simplifies operation of the Optimer. Section Control allows the stubble cultivator to raise and lower itself automatically at the headland without driver intervention. In addition, the SST offers the option of headland turning mode, either on the carriage via the transport wheels, or on the roller to reduce soil compaction. The automatic folding sequence ensures optimum safety. The GEO function can be used to modulate working depths using a map entered beforehand, or to record the working depths achieved.

Focus on Auto-Line function

The Auto-Line function corrects the machine’s alignment with the tractor’s axis of travel by adjusting the working depth of each row of discs.

On slopes, the machine slides naturally in the direction of the slope. A coulter in the center of the machine measures the drift angle, which varies according to the direction and size of the slope.

The Auto-Line system modifies the horizontal position of the machine by differentiating the depth of the front discs from the rear discs to obtain an angle at coulter level that tends towards. This angle is measured continuously during work and the horizontal position is corrected if necessary.

To ensure even stubble cultivation, the system allows a maximum depth difference of 3 cm between the front and rear discs.

Hydraulic actuators (cylinders) are used to continuously modify the horizontal position. They are controlled by solenoid valves, which in turn are controlled by the Optimer computer according to the positions indicated by the coulter. The system is completely autonomous and independent of the tractor.

A stubble plough that works straight allows finer adjustment of the GPS width, as close as possible to the actual width of the machine. Crossover is reduced and the angle of attack of the discs is maintained for optimum stubble cultivation. The uniform working depth reduces fuel consumption by avoiding over-deep spot cultivation, and ensures optimum germination of the crop to be planted.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)