The AVR Spirit 9200 2-row potato bunker harvester has been on the market already for some years. Over the course of time, the machine has further been improved to meet with market demands. The latest expansion of the 9200 Series is the Spirit 9200i with various new and updated features.

In line with the concept of the current Spirit 9200, the Spirit 9200i offers a number of important upgrades in the area of control, traction, haulm web, pintle belt module, cross-roller module and the Clean & Go hopper. Key features of the Spirit 9200i are improved (cleaning modules), intelligence (automated functions) & intuitive ease of use.

ISOBUS

The machine’s drive system is compatible with ISOBUS. AVR can offer a Müller Touch800 or Smart570 screen for this purpose. The machine also comes with an ergonomic joystick as standard, and thanks to the ISOBUS-AUX system, various functions can also be controlled via the tractor joystick. Clear icons and intuitive menus, supplemented by the automatic functions of the machine serve to optimize the user-friendliness of the Spirit 9200i.

Sieving capacity / drop heights

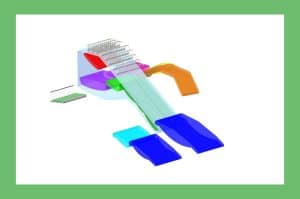

The up to four sieving webs for the pintle belt module ensure maximum sieving capacity. Either two short digging webs or one long digging web can be attached to the front of the machine. An additional digging web – and therefore one more drop increases the machine’s sieving capacity. If the soil can be sieved easily and for the gentlest treatment, a single long web is the best option.

A soft sieving web with rubber fitted, can be attached directly in front of the pintle belt module, or a cross-roller module for additional cleaning capacity is possible. Drop heights are kept to a minimum throughout the machine. Because the haulm and sieving webs are so close to one another, the drop height from the digging to the sieving web is limited to the greatest extent possible. Thanks to this mechanism, the AVR Spirit 9200i guarantees low drop heights.

Haulm

The primary haulm separation system is a combination of the sieving web and the haulm web. A set comprising two rows of retainers and another set comprising three rows of retainers mounted above the haulm web ensures that the potatoes stay in the machine. These sets are individually adjustable in height, and the rows of retainers have been mounted to ensure an adequate distance in between the rows to optimize the machine’s separation capacity. In the event of an accumulation of haulm, the frames of the rows can be folded upwards.

Another three rows can be added at the top of the machine. A closed conveyor is located underneath the haulm web that discharges the haulm and allows any potatoes that have accidentally been carried along with the haulm to roll back into the machine.

The third sieving web or the cross-roller set increases the separation surface (haulm web) for long haulm or weeds from the product flow. This is of crucial importance, considering the current trend which favors high-yield varieties with a lot of sturdy haulm.

Additional cleaning capacity

A cross-roller set for the pintle belt unit increases the machine’s cleaning capacity, without the need for additional directional changes in the machine.

The cross-rollers remove loose soil, clods, and smaller stones from the product flow, thus relieving the pressure on the pintle belts and allowing them to remove the remaining loose soil and haulm more efficiently. The position, speed and rotating direction of the smooth rollers can be adjusted on the display screen via a handy widget. The last roller of the CR module has also been fitted with rubber and, in combination with a brush bar, serves as an efficient haulm roller.

The cross-roller module’s infinite adjustment options allow the digging unit to be used in every situation.

Pintle belt module

The pintle belt module at the rear of the machine is fully adjustable in terms of incline and guarantees full control over the product flow under all circumstances, regardless working on a slope or a flat surface, or on light or heavy soil. The product flow on the in-line pintle belt is guided via the triple retaining roller which is height adjustable, to the transversal pintle belt equipped with two 2-row rotary combs. This is where stone and clod separation takes place before the final inspection on the picking-off table.

The hydraulically collapsible retaining roller on the transversal pintle belt can be operated from the cab. This means that obstructions can easily be avoided, even in the most difficult sections of your plot.

Picking-off table

The large picking-of table offers enough space for six people to perform a final inspection. All the settings for the cleaning modules can be operated from the picking-off table via the convenient keypad.

(Clean & Go) bunker

The Spirit 9200i is equipped with a bunker with a capacity of just over 8 tons. The unloading height can be adjusted up to 4.20 m, for which a hydraulic collapsible shock absorber or crate-filling funnel is available.

A Clean & Go bunker is also an option. This means the best of both worlds: a buffer for 8 tons of potatoes, additional sieving capacity and no need to stop the machine in order to unload the bunker!

Traction

Hydrostatic wheel drive is available optionally. An additional hydraulic pump drives a 2815 cc wheel motor on the right wheel and a 1745 cc wheel motor on the left wheel. Consequently, the rear axle is provided with a traction capacity of 120 hp. The traction system – which is even more powerful than in the previous model is user-friendly. It can be operated via a supplementary keypad, while the ISOBUS control automatically detects whether the machine is moving forwards or backwards.

AVR Connect

The Spirit 9200i can be fully monitored remotely, online. An AVR Connect account allows to monitor data in relation to the work performed, sensor data, alarms and yield data. Remote diagnostics are possible for support from dealer or AVR.

In 2023, the prototype was extensively tested. Seven Spirit 9200i harvesters were subsequently manufactured in a pre-production run in 2024. The Spirit 9200i will be on display, fully operational in a demo set-up, for the first time at the Potato Europe trade fair on 11 and 12 September in Villers-Saint-Christophe, France.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)