To mark having produced a total of 500,000 combine harvesters, CLAAS is presenting an exclusive series of anniversary machines. For that purpose, the company relies on a close cooperation with paint manufacturer Mankiewicz.

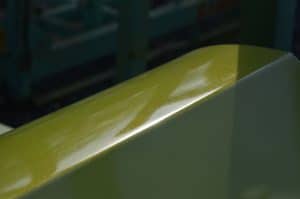

The unique colors of ag machine’s makers identify their brand and can be recognized from far away. As a prominent manufacturer of combine harvesters, CLAAS has delivered over 500,000 of these machines in their iconic seed-green outfit to farmers and contractors worldwide. To ensure that this milestone is presented in its best possible light, Mankiewicz Coatings has developed, together with CLAAS, a remarkable new coating system. Target requirement of the special new paint is a stunning metallic look in the CLAAS corporate colors as well having the customary robust and durable properties.

Direct-to-Metal in metallic look

The coatings experts at Mankiewicz worked closely with the CLAAS team to develop the right colors for the desired finish of the special machines. For consistency with earlier combine harvester models, the colors silver and seed green were a must – but this time with a metallic effect for exclusive brilliance. To achieve this, Mankiewicz developed a metallic topcoat with DTM properties, which was thoroughly tested at its in-house test center for corrosion protection, UV resistance and other mechanical and chemical effects. The result is a robust metallic coating solution that can be applied both as a topcoat to primed or pre-coated substrates and directly to pre-treated metal using the classic painting process.

Nine combine harvesters have been upgraded this way so far, seven of them at the Harsewinkel headquarters and two at a CLAAS location in the USA at Omaha, Nebraska. While eight of these machines are already in use, one is still on its way to Australia where the harvest does not begin until October. A tenth machine will also be painted for the Chinese market at the CLAAS plant in Gaomi, China, in time for the anniversary.

Elaborately designed stickers with “500000” complete the overall picture of the anniversary machines, including the models LEXION, TRION, EVION and DOMINATOR. “Up to 60 parts of each machine had to be removed from pre-assembly, basic assembly and final assembly. These were upgraded and returned to the assembly process. Thanks to the efficient coating process and excellent cooperation of everyone involved, it all went very smoothly,” remarks Matthias Mumme of Group Communications at CLAAS.

Efficient and innovative coating

In addition to features of appearance and robustness, efficiency was a top priority while developing the paint. This has resulted in a metallic DTM Topcoat that can be painted in one coat, unlike conventional two-coat systems and three-coat metallic systems, which require a clearcoat. This new coating expands the DTM portfolio of Mankiewicz. The system also saves material costs and significantly reduces process times. At the same time, the gloss level and protective effect of the surface are retained, which ensures the special CLAAS combine harvesters can be used in all weathers and under a wide range of harvesting conditions. It is always difficult to get good coverage in a single coat when using a bright color like the seed-green, which gives CLAAS its unmistakable brand identity, and to do so is truly remarkable.

Partnership and expertise

Realization of the project was based on a long-standing cooperation between CLAAS and Mankiewicz. The global paint manufacturer has been supplying customized coating systems for various CLAAS components for over a decade. Not only does Mankiewicz supply CLAAS factories around the world, but also its supplier network with customized coating systems that meet local and factory-specific requirements.