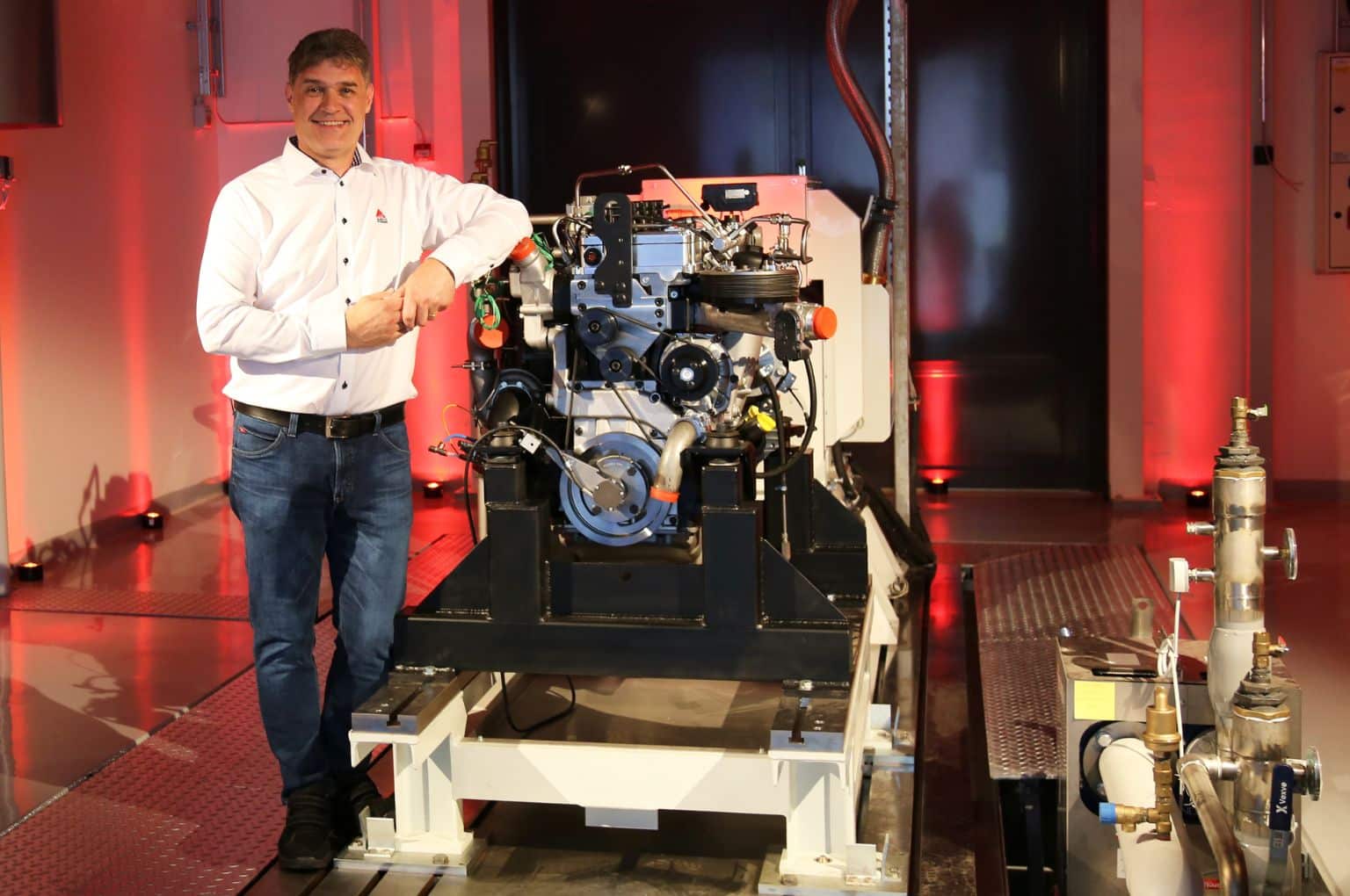

AGCO Power opened its clean energy laboratory. The lab is part of a 70-million-euro investment (approximately $77 million) in the Linnavuori plant in Nokia, Finland, and will support development and testing of innovative, sustainable battery and powertrain solutions for farm machinery.

The Linnavuori team of scientists and engineers are developing next-generation engines powered by low- or zero-carbon electricity and alternative fuels, such as hydrogen and methanol, that will help minimize global agricultural emissions.

While the number of hybrid and electric vehicles on world roadways has grown exponentially in the 21st century, adoption of alternative power for off-road/farm machinery has lagged. The capacity of existing battery technologies restricts the size of fully electric farm machinery, but the AGCO Power lab is working to change that paradigm.

“We are investing heavily in the research and development of multiple lower carbon technologies, such as the electrification of off-road machines and hybrids,” said Kelvin Bennett, AGCO’s Senior Vice President of Engineering. “It is exciting to know those investments will start showing tangible results this summer when AGCO’s first fully electric tractor, the Fendt e100 V Vario, enters production in 2024. “

In addition to the off-road machine emissions, AGCO is aggressively pursuing reductions in emissions in its own operations. Specifically, it has set objectives to reduce its Scope 1 and Scope 2 emissions 55% by 2033 and 90% by 2050.

Development of next-generation zero- and low-emission machines is a focus of the company’s sustainability ambition as it seeks to reduce its Scope 3 emissions. Key initiatives include decarbonizing its product portfolio, engaging suppliers to decrease their emissions, supporting farmers’ transition to sustainable solutions, and working with industry associations on renewable and low-carbon fuels in agricultural machinery.

In addition to the clean energy laboratory, the Linnavuori plant features new production facilities for both cylinder heads and continuously variable transmission components, expansions to the paint shop and testing facilities for remanufactured engines, and a training and visitor center. In total, the new buildings cover an expanse of 11,000 square meters (approximately 118,400 square feet), with some phases of the project opening this year and others set to be operational in 2025.