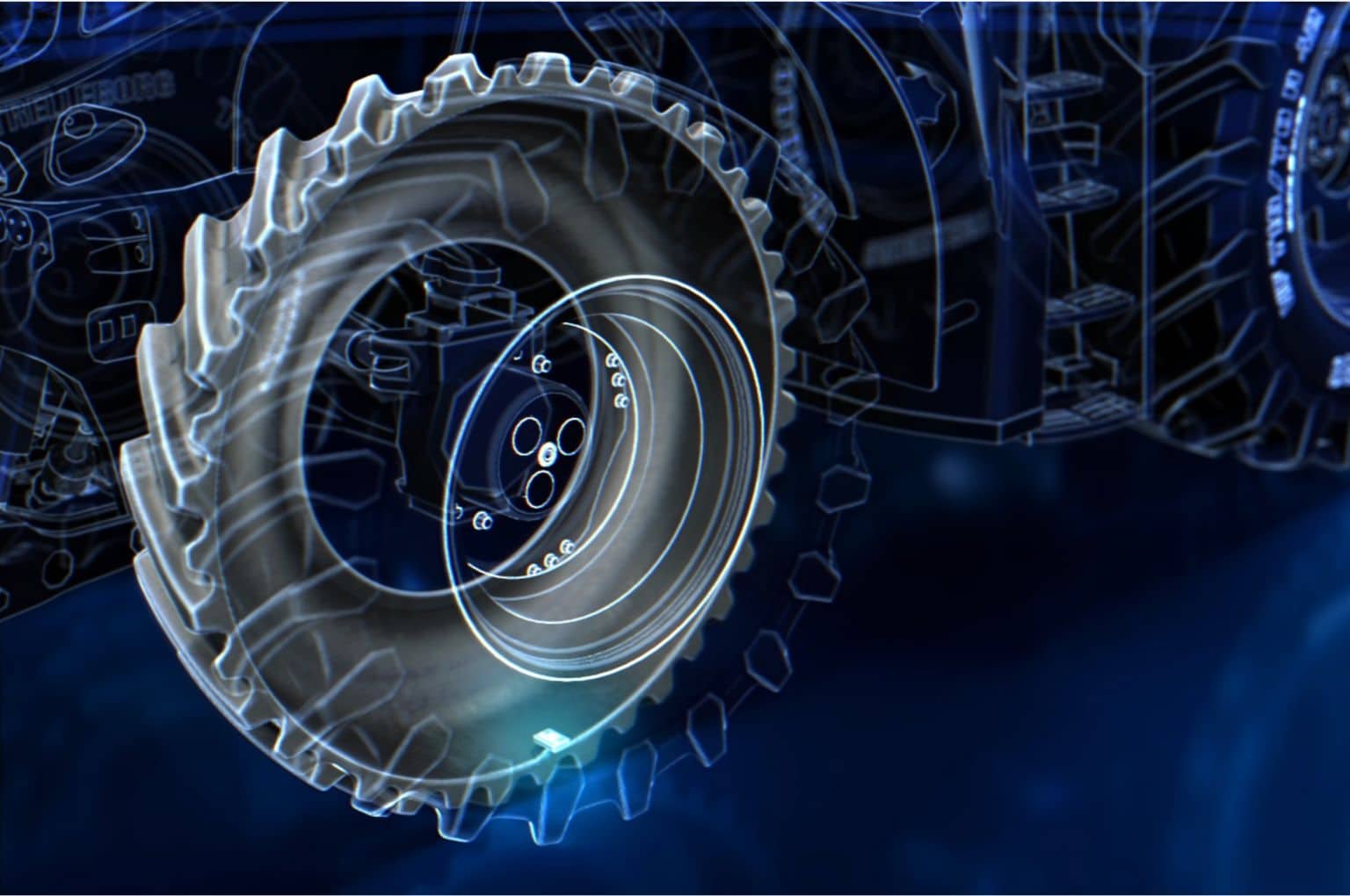

With the help of the new Trelleborg Adaptive Tire Management System (ATMS), a tractor will always work effectively according to the kind of work. Through sensors, mounted on a tire integrated support, the system detects the tire working conditions, acquiring in real time dynamic load, pressure and temperature.

ATMS is able to measure the dynamic load of each tire. As a result, the driver is constantly advised on how to fully optimize the tractor configuration, in each working operation, through:

- the most appropriate tire inflation pressure

- the correct tractor ballast and implement set up

- the inputs for the tractor engine and transmission management

The data acquired by the sensors are elaborated by the gateway and shared with the driver through the tractor video terminal.

In combination with a CTIS system, ATMS enables the vehicle to manage adaptive pressure in a more effective way. The system infrastructure can be customized for different agricultural machines including tractors, harvesters, and trailers.

By adopting ATMS, tire pressure and tractor load distribution are managed efficiently resulting in higher productivity. The optimization of these 2 parameters leads to the best possible results:

- Low soil compaction due to the optimized footprint

- Reduced working time due to higher traction and low slippage

- Improved drivability on the road, due to the correct tractor configuration

- Reduced fuel consumption, both in field and on road applications

The advantages of ATMS are its new functionalities, such as the tire dynamic load, the tractor load distribution and the recommended tire pressure. ATMS is providing the most important data to reach cost-effective sustainable agriculture. This is achieved by maximizing vehicle operations, reducing working time and fuel consumption.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)