The Amazone CurveControl software option, adjusts the lateral distribution to the various cornering speeds and corrects the movement of the spread pattern in centrifugal fertilizer broadcasters when driving around bends. This results in more uniform crops and helps prevent undesired over-fertilization inside the bend as well as fertilizer placement beyond the field boundary. The system has been awarded with an Agritechnica silver medal.

Curve compensation has already been implemented by Amazone in crop protection sprayers. However, the sprayer boom is located tight behind the physical pivot point of the machine. The application rate only has to be adjusted within the boom width for curve compensation.

The throwing distance of a centrifugal broadcaster is up to twice the working width and the application area is many meters behind the spreader, depending on the type of fertilizer. Furthermore, the spread fan is kidney-shaped. In addition to the rate adjustment on the inside the bend, the movement of the spread pattern from the spreader must first and foremost be counteracted.

All this demands detailed knowledge of the way that the spreading unit works with the various fertilizers along with a corresponding complex implementation of a control algorithm. CurveControl therefore requires an exceptionally high degree of innovation and complexity for a fertilizer spreader.

The current state of the art of modern centrifugal broadcasters has the disadvantage that over- and under-fertilized areas inside of the working width occur when negotiating bends as a result of different speeds. This effect is amplified by the combination of forward speed and swiveling of the spread pattern caused by the steering angle. This means that significant over-fertilization arises in some areas as a result of these multiple overlaps, whereas gaps occur in other areas.

In addition to this, the swiveling of the spread fan at the edge of the field causes fertilizer to be applied beyond the field boundary. This must be avoided without fail with regard to resource conservation and to abide to the applicable regulations.

Perfect fertilizer distribution around curves

CurveControl is being developed as a software option for the ZA-TS mounted fertilizer spreader and the ZG-TS trailed fertilizer spreader. The system prevents under- and over-fertilization, which is undesirable from an ecological and economic point of view, and thereby minimizes the risk of nutrients leaching into the ground water. Furthermore, incorrect application beyond the field boundary when negotiating bends is prevented by CurveControl. In addition to this, CurveControl can further improve the environmentally-friendly use of mineral fertilizer in combination with existing solutions such as ArgusTwin, WindControl and GPS part-width section control.

In summary, CurveControl closes an important, frequently underestimated gap and provides even distribution in all areas of the field. It will not only make a key contribution to environmental protection but will also improve the cost benefit result for every application.

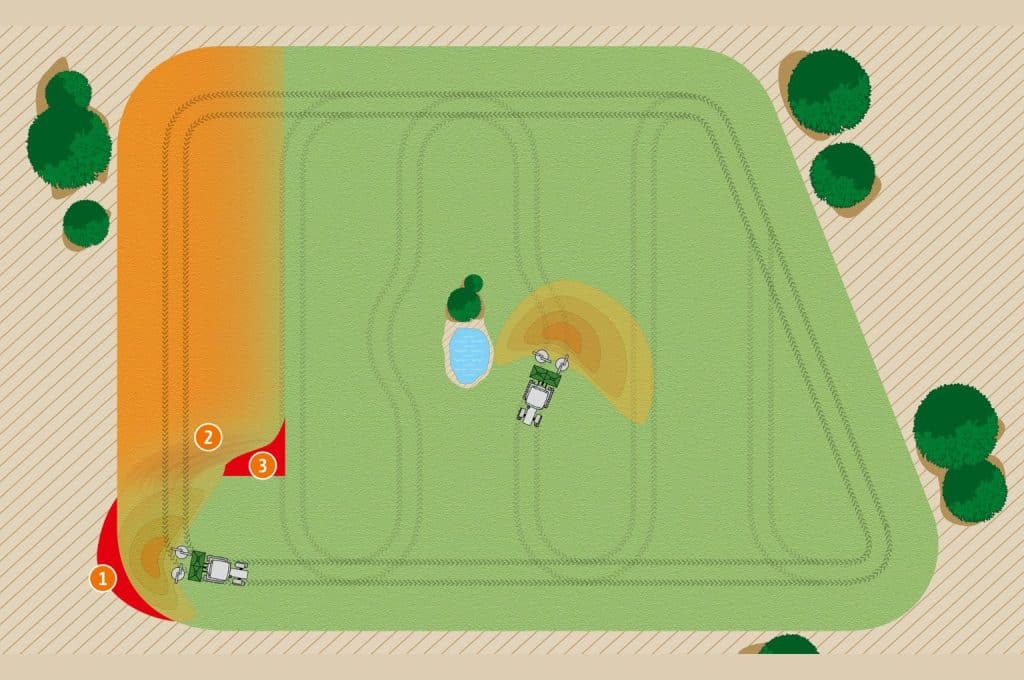

Effect on fertilizer distribution when negotiating bends

1 Incorrect application beyond the field boundary

2 Over-fertilization as a result of multiple overlaps

3 Under-fertilization caused by the move in the spread pattern

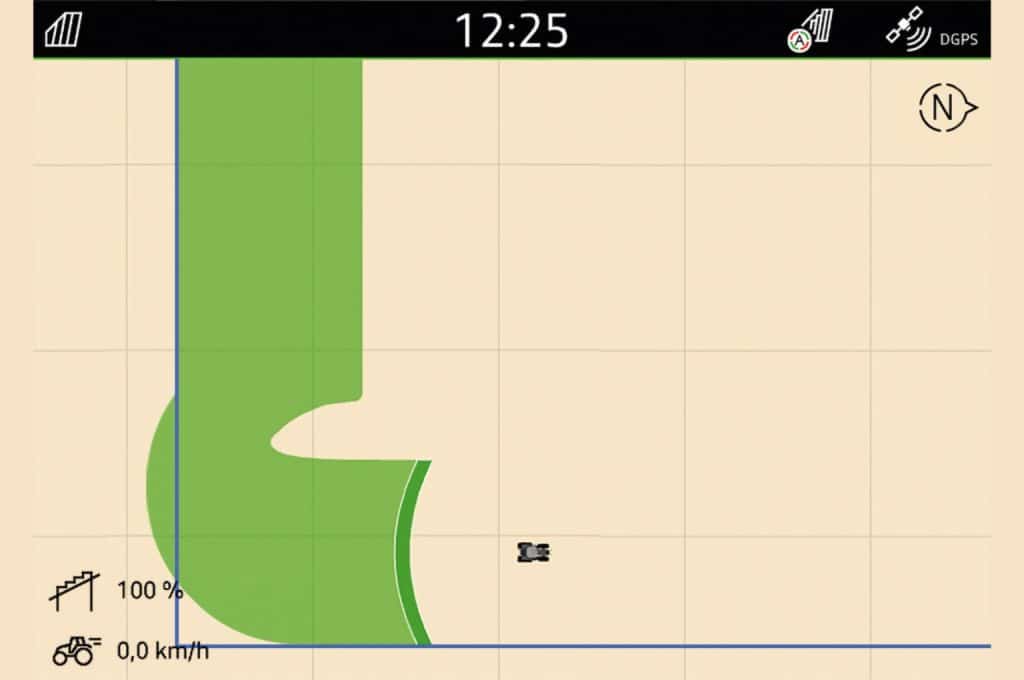

GPS view of a curve without CurveControl

The spread fan is located many meters behind the tractor and undesired swivel movements occur

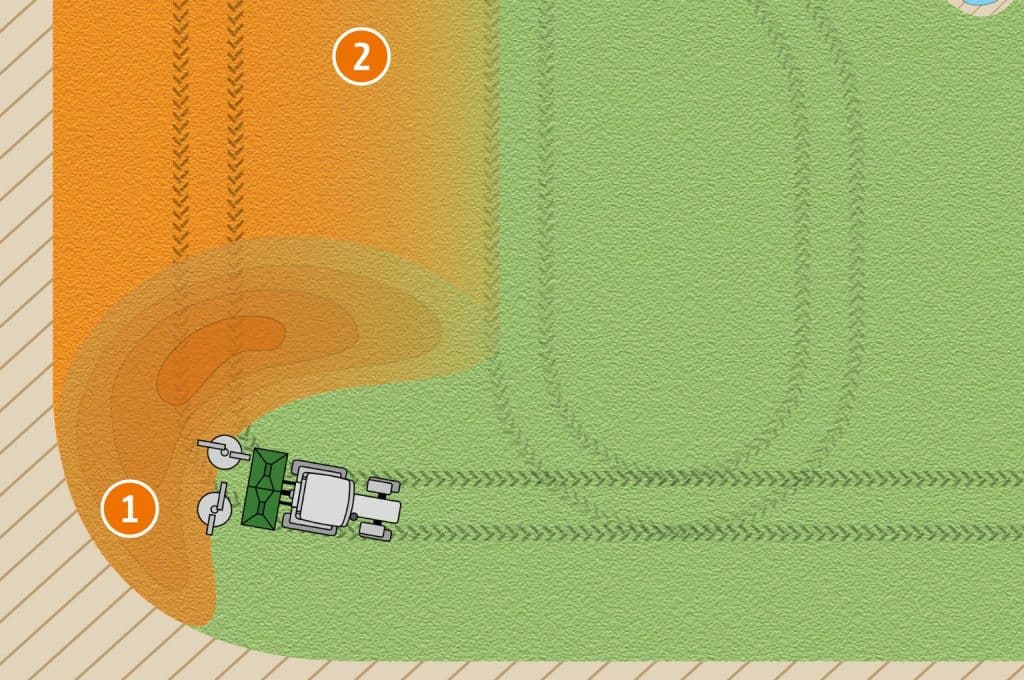

Perfect fertilizer distribution through CurveControl

1 No incorrect application beyond the field boundary

2 Even fertilizer distribution in all field areas

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)