With a maximum working width of 15.70 m, the new Krone Swadro TC 1570 with V-frame concept is closing the gap between the Swadro TC 1370 with four rotors and the Swadro TC 2000 with six rotors. It makes the Swadro TC 1570 a useful addition to the professional rake segment. The machine ensures high acreage output, quiet running and maximum operator comfort.

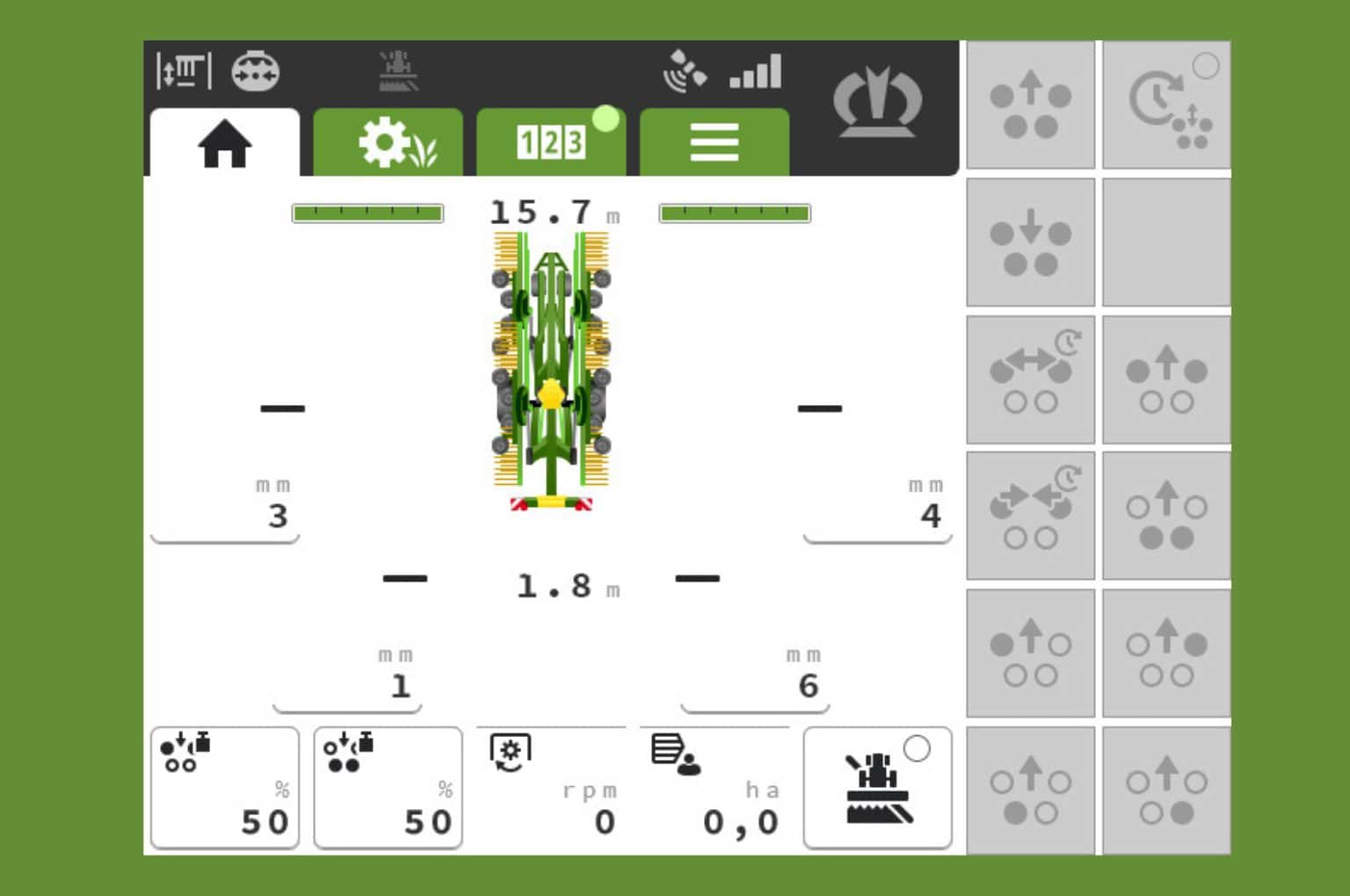

With the new Swadro TC 1570, Krone adds a new four-rotor rake. In addition to other technical features, it has been designed according to Krone’s well-proven V-frame concept, adapted from the largest centre rotor rake, the Swadro TC 2000. This concept gives the machine not only a flexible working width of up to 15.70 m, but is also extremely stable and smooth running.

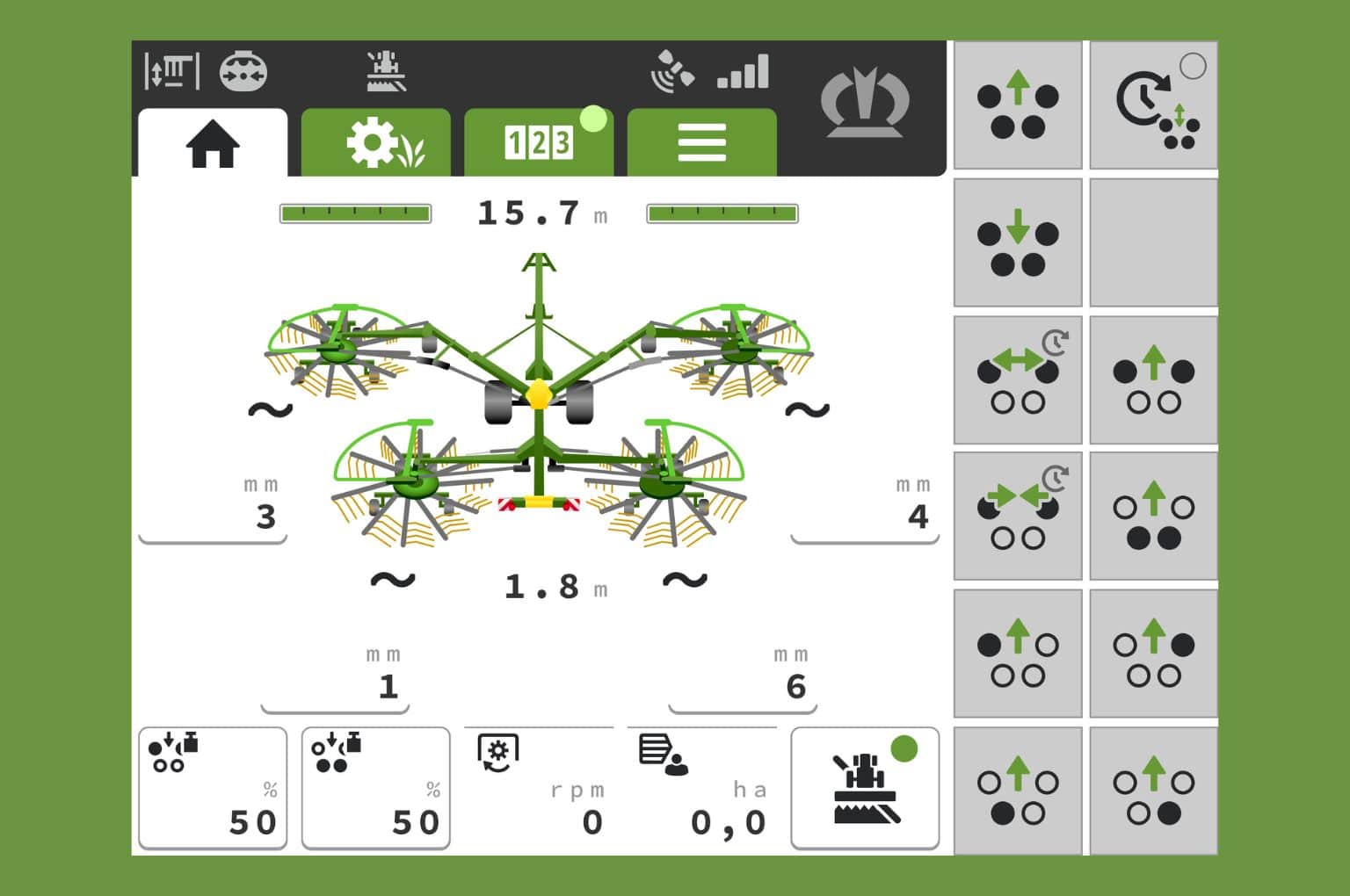

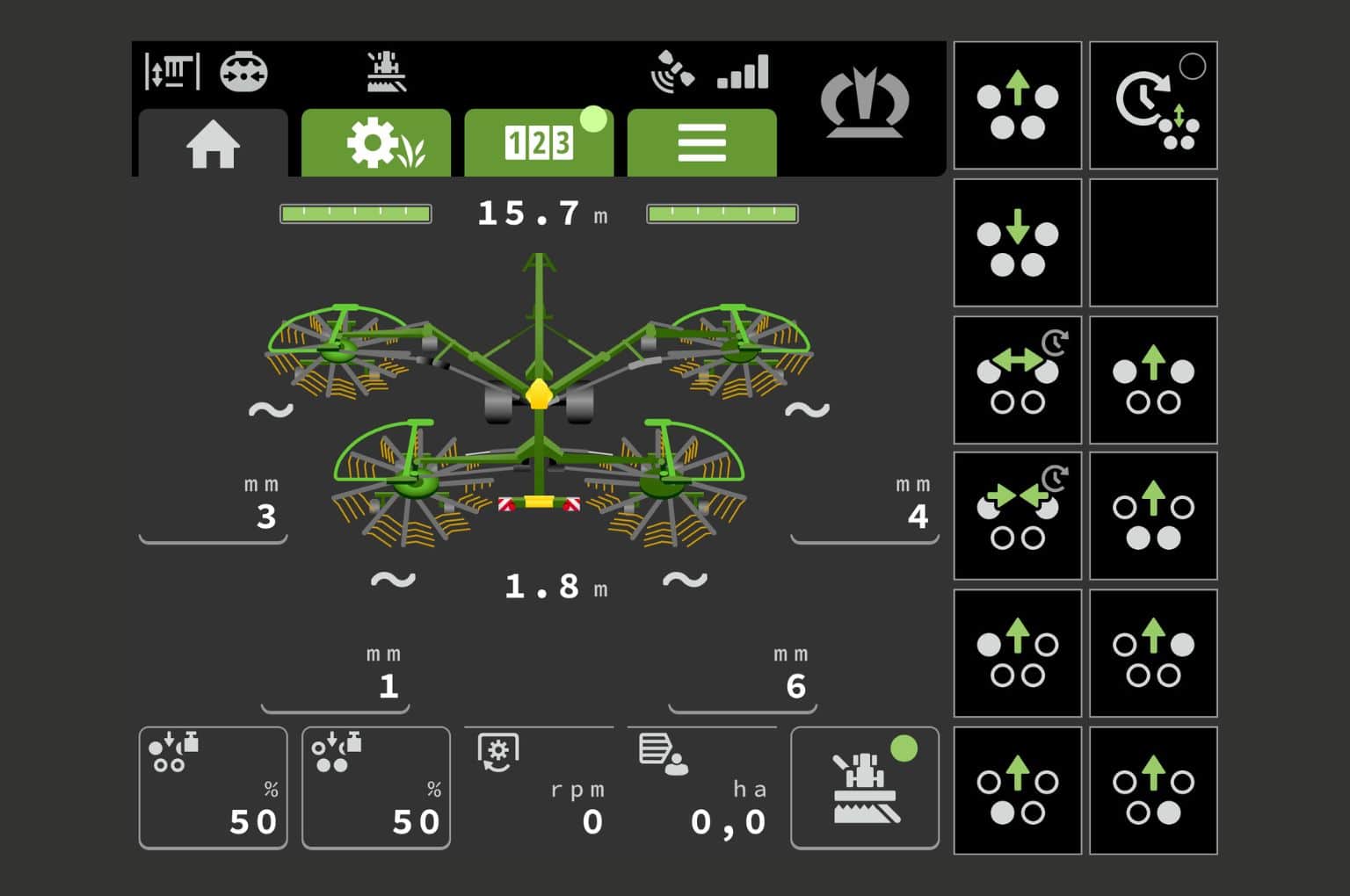

With the new clear and intuitive user interface, the entire machine can be operated from the tractor cab via an ISOBUS-compatible terminal or in combination with an ISOBUS joystick. In this way, the Swadro TC 1570 always achieves the best raking results, even under difficult conditions.

The working width of the four-rotor rake centre delivery can be variably adjusted up to 15.70 m via the front rotors guided by the V-outriggers. As the two V-outriggers can be retracted and extended independently of each other, field corners and obstacles can also be raked out effortlessly. In addition, the outriggers are each supported by a support wheel in the front area. As a result, the machine is characterised by quiet running, especially at high speeds and also during fast turning manoeuvres at the headland. This results in maximum acreage output and maximum efficiency.

Equipped to the maximum

15 tine arms on all four rotors and five tines per tine arm on each of the two rear rotors enable loss-free raking even at high driving speeds. The lift tines lift the crops cleanly from the sward, even at higher working speeds, and have been proven to reduce the amount of dirt entering the forage. The mechanical Easy-Line drive concept stands for efficient power transmission and allows the front two rotors to rotate about 25% faster than the rear ones. This ensures optimum forage flow inside the machine and tangle-free, box-shaped swaths. Thanks to the hydraulically adjustable outrigger arms of the rear rotors, the swaths can be produced in a width of 1.40 m to 2.90 m. This means that the following harvesting machines, whether baler, loading and forage transport wagon or harvester, can always be optimally utilised.

The Swadro TC 1570 is equipped with a category II/III pendulum-suspended two-point hitch. This reliably compensates for uneven ground and gives the rake enormous manoeuvrability thanks to its large steering angle. Thanks to the hydraulically lowerable main frame, the machine can be lowered to a transport height of less than 4 m without folding down tine arms for road travel. In the working position, the main frame, which is moved upwards, ensures that forage flows reliably inside the machine, even if the forage masses are large.

The transport chassis is equipped with 710/40 R 22.5 tyres as standard. The optional 800/35 R 22.5 tyres provide even more contact area. Together with the wide 16×9.50-8 four-wheel rotor chassis tyres (optionally six-wheel rotor chassis) and the 15/55-17 support wheels on the two outriggers, the result is a perfect combination of driving stability and work which protects the sward.

Equipment without compromise

In order to always achieve the best raking and forage quality under all conditions, the Swadro TC 1570 is equipped with numerous features as standard.

With the electrical rotor height adjustment, the raking height can be easily adjusted to different field and forage conditions at any time via the operating terminal. The height of each rotor can be adjusted individually or all rotors can be adjusted simultaneously. In addition, two self-selectable heights can be saved on the terminal and activated at the touch of a button.

The hydraulic rotor relief integrated in the lifting cylinders ensures optimum bearing pressure of the rotors. This hydraulic rotor relief can be set separately for the front and rear rotors via the terminal, even while driving. Here, too, two values can be saved and accessed by pressing a button. When adjusting the working width or swath width, the relief pressure is automatically adjusted by an active control system so that the rotors are always evenly relieved – regardless of the working width or swath width. Together with the gimbal rotor suspension pulled by the outrigger arm, the rotor adjusts optimally to the ground contours under all conditions – this protects the sward and prevents dirt from entering the crops.

Automatic lowering mechanism

In addition to the V-frame concept, the integrated vibration damping also ensures that the machine runs smoothly in the headland position. In addition, a Soft-Down automatic lowering mechanism ensures that the outrigger arms are decelerated just before the rotors touch down, ensuring that they touch down gently on the ground. This protects both the machine and the sward, minimises the turning times at the headland and increases the acreage output!

Further potential for optimising the turning times is offered by the possibility of adjusting the machine to the needs of the driver. According to the motto “As low as possible, as high as necessary”, the lifting heights of the rotors can be set via the operating terminal. At the headland, for example, they only lift as far as is absolutely necessary so as not to destroy existing swaths again. The lift delay of the rear rotors with respect to the front rotors can also be adjusted from the cab. You can choose between a time-dependent or path-dependent delay.

Lifting and lowering can be controlled even more comfortably using the Section Control partial width switching. In doing so, the rotors are lifted and lowered fully automatically with the aid of GPS positioning. This relieves the driver and also increases the acreage output.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)