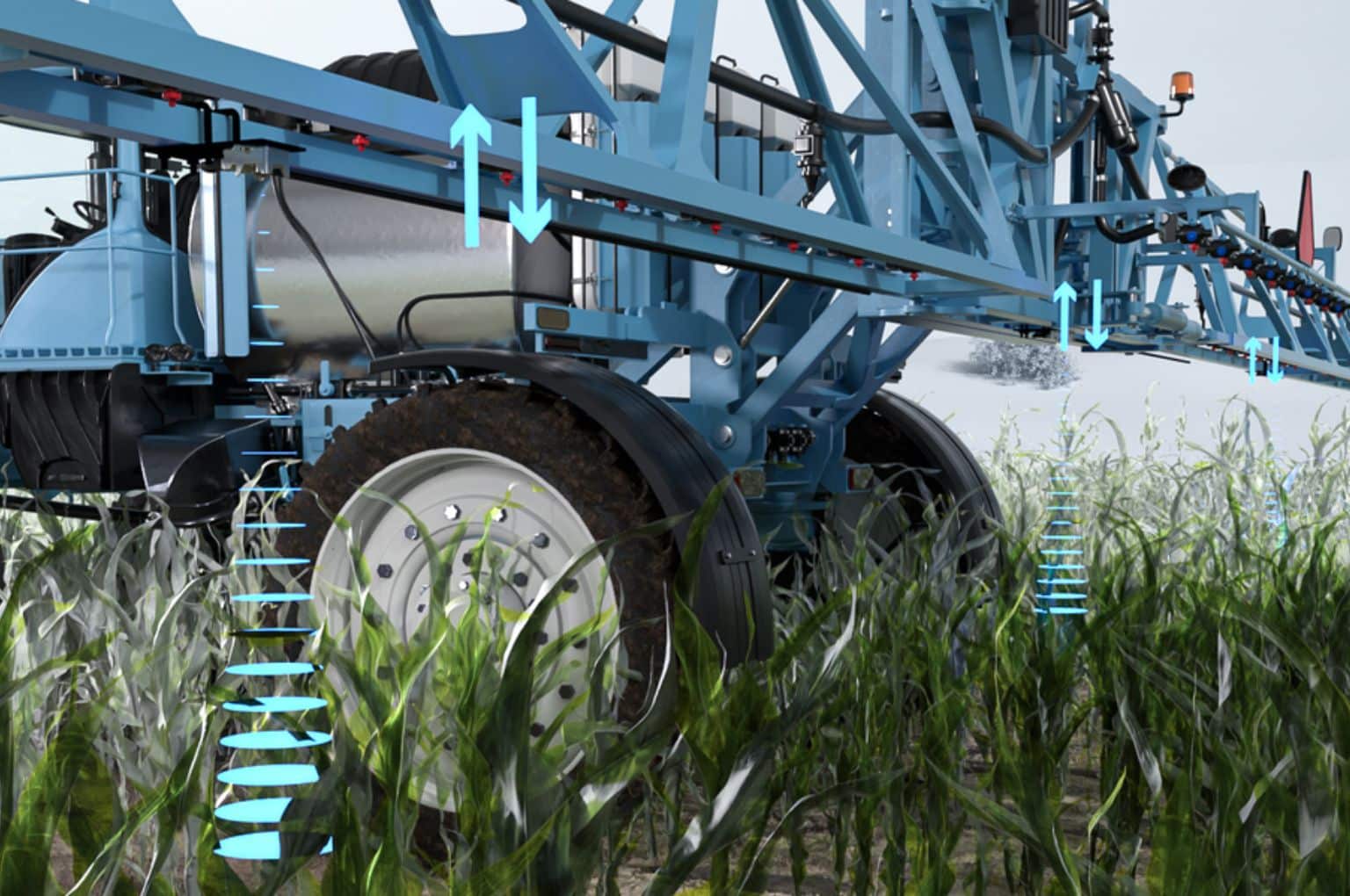

They are giants in the fields, sprayers with a span of up to 40 meters are used to spray crop protection agents. The distance is key in this process. If the sprayer boom is too high, some plants are not treated sufficiently because the wind blows the droplets away. If the sprayer boom is too low, some plants are not treated at all. Radar sensors appear to precisely detect the distance.

To prevent too much or too little agents ending up in the field, modern agricultural sprayers are equipped with boom height sensors. Depending on the height of the crop, the actuators regulate the height of the sprayer boom, at the same time compensating for uneven terrain and changes in the height of the plants. Different application, same challenge – asphalt finishers constantly measure the height of the ground to make sure that the pavement is subsequently applied evenly at the correct thickness.

Current solutions

Many vehicles in the agriculture and construction sectors are equipped with ultrasonic sensors to measure distances. Almost everybody uses them daily when parking – they emit silent acoustic pulses that are reflected by a car behind the parking spot. The time until the echo is received can be easily converted to the distance, and the increasingly fast beeps that warn drivers of collisions. Yet what works reliably when parking is not always the ideal solution for agricultural and construction machines. As a general rule, ultrasonic sensors detect the distance to the next obstacle, which is the top of the crop in the case of agricultural sprayers. They do not measure the distance to the ground, or if they do, then only with elaborate signal processing outside the sensor, and even then they are not very reliable. In addition, they are not very fast because even with distances of a few meters, the speed of sound starts to play a role. What is more, wind or rising hot air may distort the results. Even the spray mist of the pesticide can affect the measurement in unfavorable circumstances. Furthermore many ultrasonic sensors require an additional protective cover for outdoor applications.

Radar sensors the better alternative

This is where radar sensors that work with electromagnetic waves come into play. Radar sensors are not affected by dust, fog, rain, wind, heat, and light; their accuracy always remains constant. The fact that ultrasonic sensors are still widely used today is also due to the long innovation cycles in these industries and the associated expense of integrating new technologies. But there is another reason: compact radar sensors have not been on the market for that long. In 2015 Baumer introduced its concept of 122 GHz radar sensor technology for off-highway applications at the Land.Technik conference in Hanover, Germany. The Swiss manufacturer has been cooperating with leading manufacturers of agricultural equipment, which have had very positive test results and have been using these sensors for many years. It is expected that radar sensors will be found in many more applications on agricultural and construction machinery in the coming years.

Single- and multi-target version

Baumer has succeeded in adapting the radar technology to the purposes of off-highway machines. These sensors operate in the frequency range from 122 to 123 gigahertz. This allows them – in combination with sophisticated signal processing – to reliably detect the height of the crop as well as the distance to the ground hidden beneath it. This is what is known as a multi-target sensor. In addition, this frequency allows a compact design with a small opening angle which makes integration into a machines easier. The R600V measures on ground and plants with distances between 300 and 5000 mm and with measurement errors of +/-6.5 mm. With its CAN SAE J1939 interface it is suitable for use in agriculture, where it regulates the height of agricultural sprayers or the header of combine harvesters, even on very uneven terrain. The power supply can be up to 32 volts, which covers the usual 12 volts of agricultural machines and the usual 24 volts of construction machines. The R600V is also available as a single-target sensor for construction machines. This version is suited for applications where the distance to only one object is to be measured.

Cleaning with a pressure washer

The multi-target and single-target versions are contained in identical fully sealed and robust housings with the protection class IP68/IP69K. They are therefore dust- and water-proof and protected against the entrance of water from pressure washers. In contrast, ultrasonic sensors often only comply with protection class IP67, which means they may not be cleaned with pressure washers, for example, which is a disadvantage in fields or at construction sites. The radar sensors from Baumer are not only suited for cleaning with pressure washers but can also withstand immersion tests. In these tests, they are brought up to the maximum operating temperature and then immersed in ice-cold water. They comply with all relevant industry standards such as EN ISO 14982, ISO 13766, EN13309, EN 61000-6-2, EN 61000-6-3, and a few more. This makes it easy for vehicle manufacturers and system suppliers to replace ultrasonic sensors with radar sensors.

Low total cost of ownership

Of course, the question that is of burning interest to machine manufacturers is: how much does it cost? The additional price of a radar sensor compared to an ultrasonic solution is quickly put into perspective because a Baumer radar sensor requires neither external signal processing nor mechanical protection against environmental influences. However, users benefit from the higher information content of the measurement results of radar sensors. This means, for example, that crop protection agents can be used in a much more targeted and dosed manner, which results in high cost savings. In addition, the radar sensors function more reliably under a wide range of conditions, an important criterion for the large areas to be treated. The total cost of ownership is significantly lower with such a radar sensor.