Ropa from Germany has developed a machine for manually planting pre-sprouted potatoes. The planter, named Gecko, combines gently planting potatoes without breaking the sprouts. It offers high effectiveness and good working conditions for the personnel. The Gecko was developed in close cooperation with the company farmsupport.

After two years of field trials and use on farms specialized in potato cultivation, the desired advantages in yield and vegetation were achieved. The Gecko provides space for 5 pallets for efficient logistics of the planting material. Options such as a protective roof, lighting, a hand washing tank or a storage compartment offer the planting staff the best comfort even under rough weather conditions. Optional drawbar steering or tramline deactivation simplifies the driver’s work.

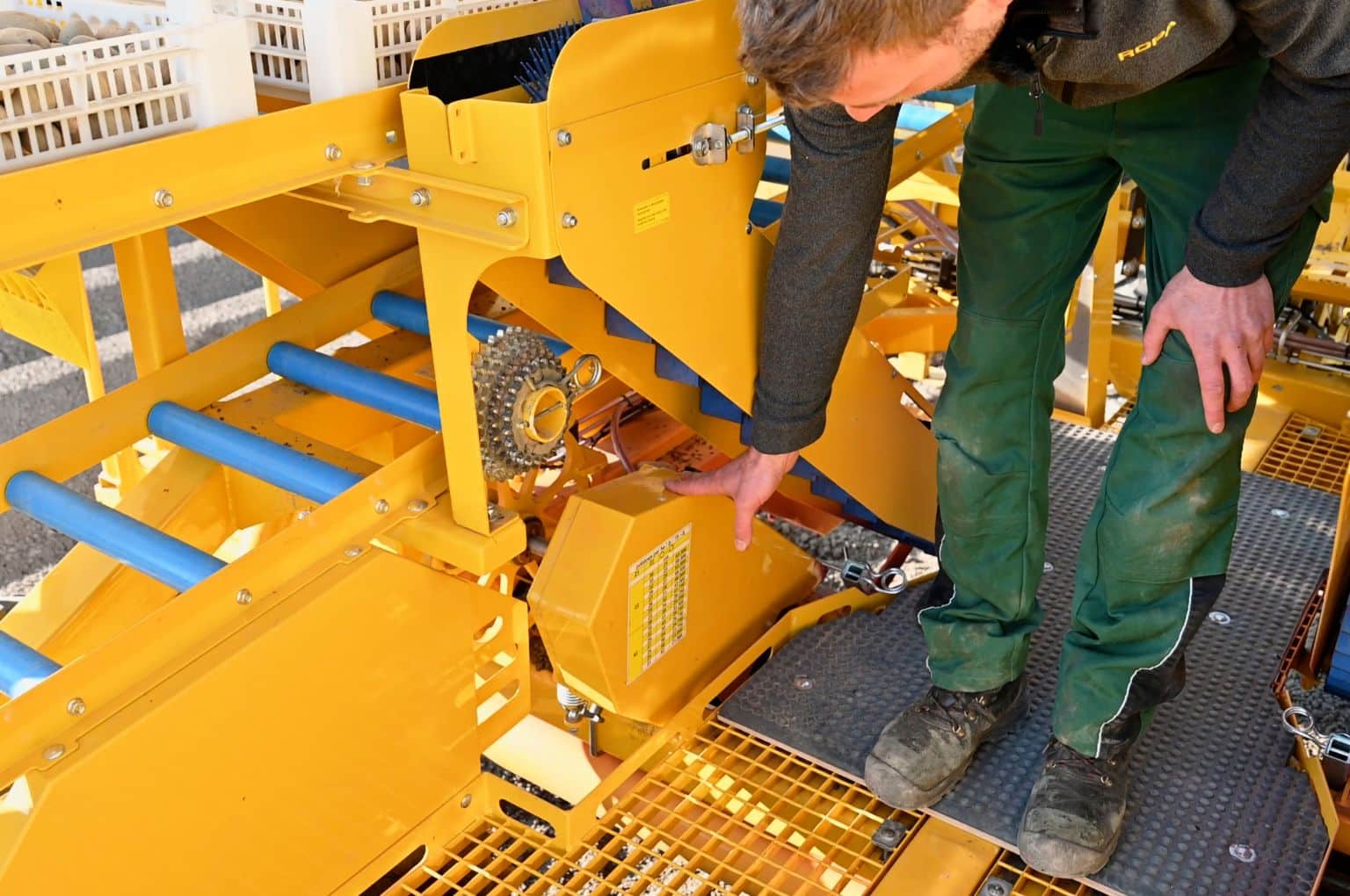

Two operators work on each planting row. They put the pre-sprouted potatoes lengthwise on the gentle and protective belts, which convey these without any further stress and grinding contact until the tubers are precisely deposited in the soil. This technology allows optimal planting of potatoes with up to 12 cm length at a driving speed of 3.5 km/h. The distance between plants can be variably adjusted in 16 stages.

This technology ensures the best possible protection of the pre-sprouted potatoes and allows to achieve daily yields of about 6 ha. The combination of the gentle treatment of the pre-sprouted potatoes and the precisely adjustable planting distance, ensures optimal planting of the potatoes as well as fast and uniform coverage of the field and homogeneous sorting of the crop.

For road transportation, the Gecko planter can be folded up to a road width of 3.0 m.

The Gecko can be ordered for the 2024 planting season and will be displayed at the Agritechnica international trade fair in Hanover, Germany, this coming November.

Technology and features:

• Planting capacity: > 6 ha per 8-hour working day

• Planting speed: 3.5 km/h

• Drawbar steering

• Mechanical drive

• Tramline deactivation

• Protective roof with lighting

• 5 spaces for pallets, 1 of which for empty boxes

• 4 rows with 75 cm row distance

• Planting distance adjustable in 16 stages

• Conveyor for boxes with box return function – easy loading and unloading

About farmsupport and Ropa

For about 15 years, farmsupport has been working solely in the field of new potato cultivation in more than 20 countries and is an expert in this branch. For example, the company invented a 360° lighting system to generate stable potato sprouts. The research based on the non-homogeneous sprouting of the potato crop helped to find what causes frequent breaking of sprouts in the planters.

Ropa has the expertise and knowledge to solve this technical problem. Both companies combined their expertise to turn a long-standing problem into a vision: planting without broken sprouts! First the prototypes were developed. They resulted in a user-friendly machine without electronics, which can be used worldwide.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)