Bergmann has been producing grain transfer trailers, the logistical link between the non-stop working combine harvesters and the goods vehicles waiting by the field, for more than 20 years. The four grain transfer trailer models of the GTW series with a load volume of 21 to 43 m³, have received an all-round makeover and now feature practical new solutions.

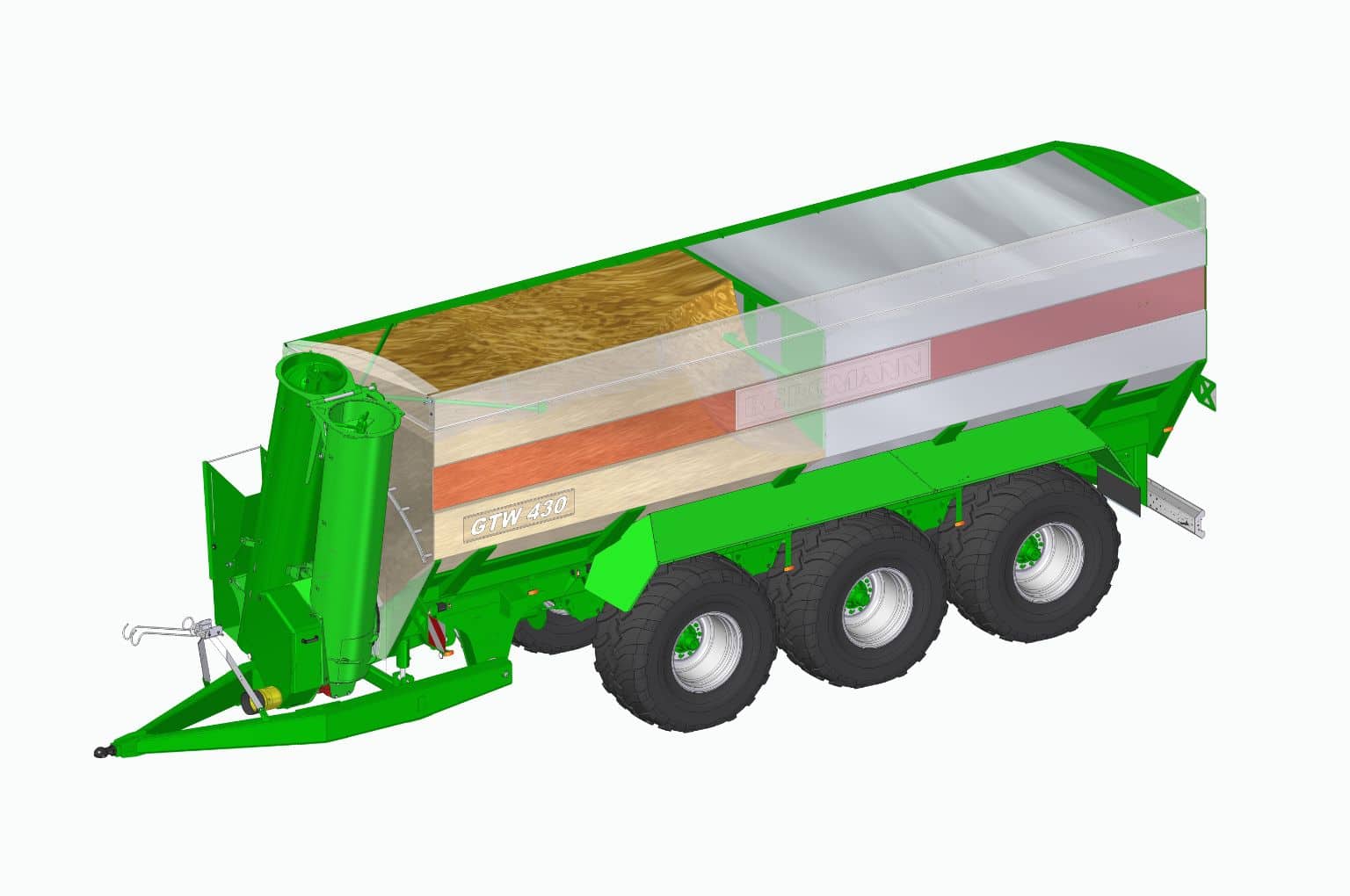

For filling seed drills with fertilizer in addition to seed, the grain transfer trailers GTW 330 (33 m³) and GTW 430 (43 m³) can be equipped with the TwinBunker split bunker system. The TwinBunker was presented at the Agritechnica 2019 together with the then new GTW 210 and GTW 300 models. It is split 50/50 into two chambers perpendicular to the direction of travel. One chamber is for seed, the other for fertilizer.

To allow independent emptying of the chambers, each chamber has an independently controllable dosing unit. To empty one chamber, the dosing unit of the other can be fully closed. For use of the GTW 330 or GTW 430 as transfer trailer for grain or corn maize harvesting, both parts of the dosing unit can be opened and closed at the same time.

Precision filling of large seed drills

For filling seed drills with large working widths, all Bergmann grain transfer trailers can be equipped with an optional hydraulically driven seed auger of 5 m length and 250 mm diameter. The transfer height and width of the seed auger are more than 4 m each, allowing convenient filling of even the largest seed drills. The seed auger is ideal for transferring both seed and fertilizer. Fitted to the lower half of the overload auger, it can be hydraulically moved from side to side and is height-adjustable.

Especially in combination with the TwinBunker, it can significantly boost the grain transfer trailer’s utilization. Allowing its use for seed and fertilizer delivery for filling seed drills and fertilizer spreaders in spring and autumn, the GTW series transfer trailers can be used all year round.

Easy maintenance

New for all models of the GTW series is a maintenance hatch at the lower end of the overload auger. This provides access to the transfer point between feed auger and overload auger, allowing a visual inspection of the transfer section as well as cleaning and inspection in the event of foreign bodies entering the bunker. It also facilitates cleaning of the transfer section.

If the grain transfer trailer is parked outdoors, covers at the ends of both overload auger sections can be opened to allow water to drain from the auger sections and prevent corrosion.

Adjustable drawbar contour

The GTW 330 and GTW 430 are equipped with a hydraulically height-adjustable drawbar in the bottom coupling as standard. The new drawbar design prevents straw from catching and accumulating when driving over swaths. The drawbar’s slim design also makes for a highly maneuverable tractor-trailer combination, while its very low weight ensures maximum payload. The optional drawbar suspension reliably absorbs impacts and vibrations for outstanding driving comfort on both road and field also at high driving speeds.

Europe-wide approval

All four grain transfer trailers of the GTW series are fully certified with complete EU type approval according to EU Regulation 167/2013 as standard. Especially when reselling within the EU, type approval is an advantage, as it removes the need for individual national approvals. The CoC (Certificate of Conformity) papers are supplied with each vehicle.

Easy data exchange

Since 2020, Bergmann is a partner in the agrirouter consortium and therefore “ready for agrirouter”. Agrirouter is a neutral, generic web-based platform for data exchange between machines and agricultural software of different makes.

The ISOBUS-compatible grain transfer trailers of the GTW series can be connected to the agrirouter in combination with a CCI 800, CCI 1200 or other ISOBUS- and agrirouter-compatible terminal. This allows the convenient transfer, for example, of machine, GPS and job data saved in ISO XML format to the Farm Management Information System (FIMS) via the agrirouter.

Modern, innovative drive concept

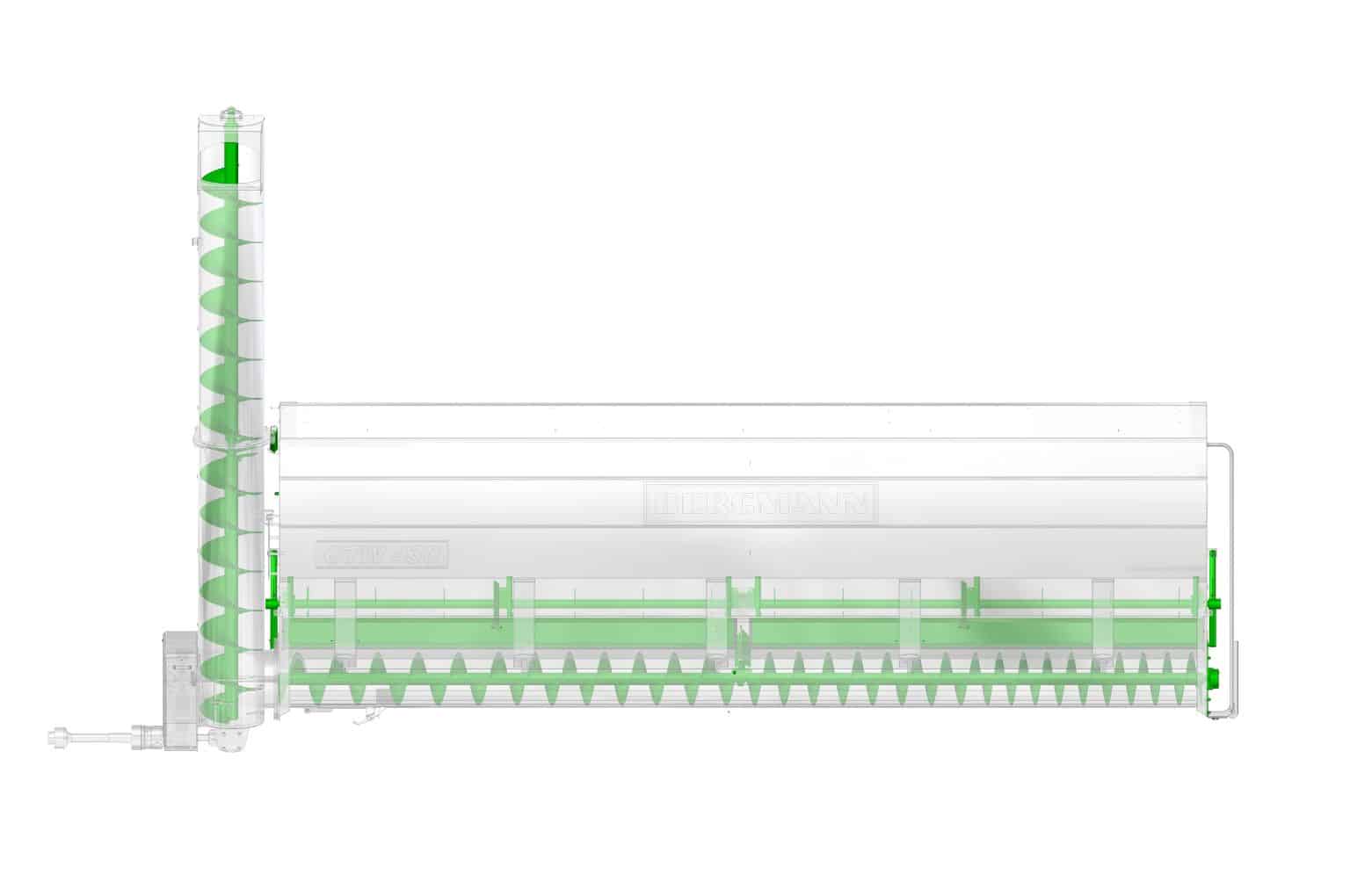

On the GTW 330 and GTW 430, the feed auger is driven via the unique Bergmann Powerband, which can also be individually switched on and off under load thanks to its hydraulic on/off system. The Powerband is driven via the tractor’s PTO. When it is switched on, a hydraulically pivoted tension roller tensions the Powerband to transmit the drive shaft’s rotary movement to the feed auger drive. For residual emptying of the overload auger, the feed auger drive can be conveniently stopped during operation, thereby allowing the grain transfer trailer to switch fields with partial loads.

The Powerband drive is low-maintenance and exceptionally quiet in operation. Power transmission is highly efficient at a tractor output of over 400 hp. The Powerband drive removes the need for roller chains and switchable clutches.

Gentle on the product

A unique feature of the grain transfer trailers is the design of the feed auger, whose inclination increases from the back to the front in four pitches.

This design has several advantages:

- The load remains in motion everywhere, so that there is no “tunnel” of stationary product within which the auger has to turn.

- Even emptying over the whole length of the body, eliminating the risk of exceeding the nose weight acting on the tractor.

- Less grain breakage, as the grain always runs into the auger over the entire length.

- Reduced tractor power demand.

Load material protection

To protect the load material from weather conditions, all grain transfer trailers of the GTW series can optionally be equipped with a manual, hand-crank operated tarpaulin.

When rolled up, it is stowed at the left upper edge of the body as seen in the direction of travel. Unrolled, it is secured with straps on the right side of the vehicle. To protect the tarp from wear, the body’s edges are fitted with small protective metal covers.

The hand crank is equipped with a hook for pulling the straps down after unrolling.

For the two large grain transfer trailers GTW 330 and GTW 430, a hydraulically adjustable tarpaulin is optional avail-able, which can be conveniently operated from the driver’s seat.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)