Krone introduces the EasyCut B 1250 Fold mower combination that suits efficient use in Controlled Traffic Farming (CTF) systems. The folding cutterbars allow safe and easy road transport of the machine.

This butterfly combination works with a maximum working width of up to 12.50 metres and is thus optimally adapted to the sward-protecting CTF concept via precise track guidance. The folding mechanism allows mower units to be folded up very compactly so that it can be easily transported on roads. Moreover, the comfort control unit provides drivers with a clear overview of the various settings and eases their workload.

Mowing in the CTF system

The EasyCut B 1250 Fold’s sliding gearbox allows for an adjustable working width, ranging from 11.30 to 12.50 m. The hydraulic side shift enables the working width of the mower units to be conveniently adjusted from the cab, with each side telescoping outwards by 60 cm. As such, the EasyCut B 1250 Fold can be ideally combined with the EasyCut F 320, F 360 and F 400 front mounted mowers by setting the appropriate overlap. This ensures a clean cut at all times while utilizing the maximum working width.

The EasyCut B 1250 Fold ideally suits use in CTF systems thanks to its working width of over 12 m. This enables work processes to be organized with maximum efficiency and possible soil compaction to be reduced to a minimum thanks to precise guidance in the tracks created. Incidentally, the weight-optimized frame design and the absence of a conditioner also contribute to this. With a weight of just over 3,500 kg, the mower can be used with tractors upwards of approx. 200 hp.

Folding cutterbar

The EasyCut cutterbar is fully welded, permanently lubricated and demands low maintenance. With its eight cutting discs and two mower drums, as well as SafeCut, SmartCut and impact damage protection system as standard, it guarantees a clean and safe cut every time. Special feature of the EasyCut B 1250 Fold is that the outer cutting disc of both mower units can be folded away to the rear using the hydraulic slewing gear. With a transport height and width of less than 4 m and 3 m respectively, the mower combination can be transported compactly and easily on roads from one site to the next. Even during the folding process, the drive train remains permanently friction locked, with the cutting discs always in the correct position in relation to each other.

Operator comfort

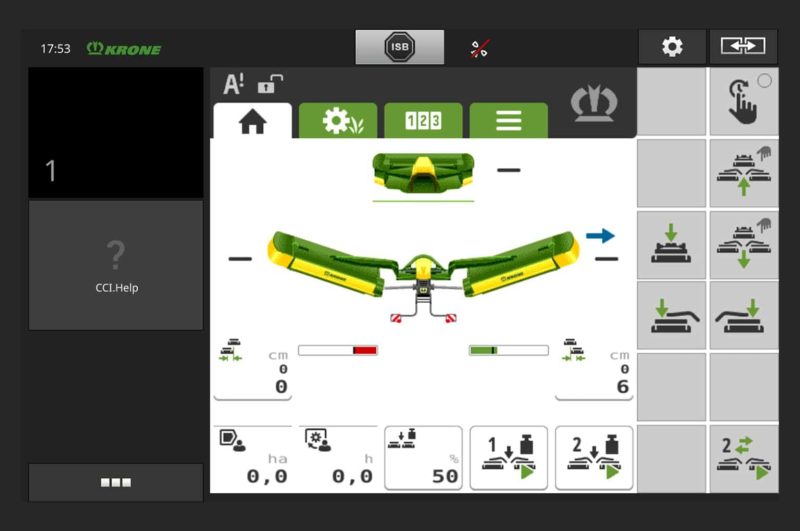

Thanks to the DuoGrip suspension, the mower units are supported at the center of gravity and guided by suspension arms. This guarantees optimum ground following even in the harshest conditions. This is supported by the hydraulic mower relief, which is infinitely adjustable from the tractor seat via the terminal. The ISOBUS comfort control unit with the new user interface ensures ease of use. With the help of animations and 3D graphics, as well as specific values, all the key functions of the machine are presented clearly and dynamically. For example, the relief pressure or lifting delay between the headland and the working position can be easily and precisely adjusted to the respective conditions.