If an implement behind the tractor is not tracking true, whether on a slope or on flat terrain, this means that the tractor’s traction line is not optimal. As a result, the power curve of the combination is not optimal. Amazone introduces AutoLane on the Catros-2TX disc harrow, to solve this insecurity.

Today, tractors with automatic track guidance are often used for soil tillage, which can follow fixed A-B lines or contour lines. These A-B lines are set based on the working width and the mounting position of the implement.

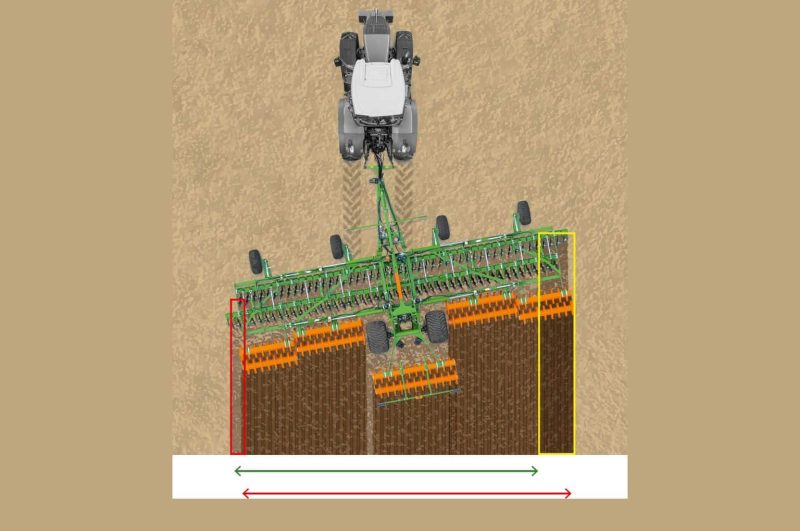

It is theoretically assumed that the implement runs straight behind the tractor when on a slope. In practice, it has been shown that, especially with trailed soil tillage machines, such as the compact disc harrows, the implement runs downhill on hilly terrain, and therefore no longer follows in the tractor’s track. Hence, the operation is not carried out properly.

With trailed compact disc harrows, there is currently no effective technical solution to prevent the implement from running downhill. There are special slope discs in some areas that can reduce, but not prevent, this phenomenon.

In order to counteract the problem of overlapping and skipping when driving track by track on hilly terrain, an additional GPS receiver could be used so that the track guidance system can adjust the A-B line of the tractor. However, this does not compensate for the diagonal pull of the implement. By shifting the A-B line to the previous track, only an overlap of the working passes is created so that no area is left unworked. Even with this approach, the result from the compact disc harrow is poorer and the traction line is not optimal.

Compensating for insecurity

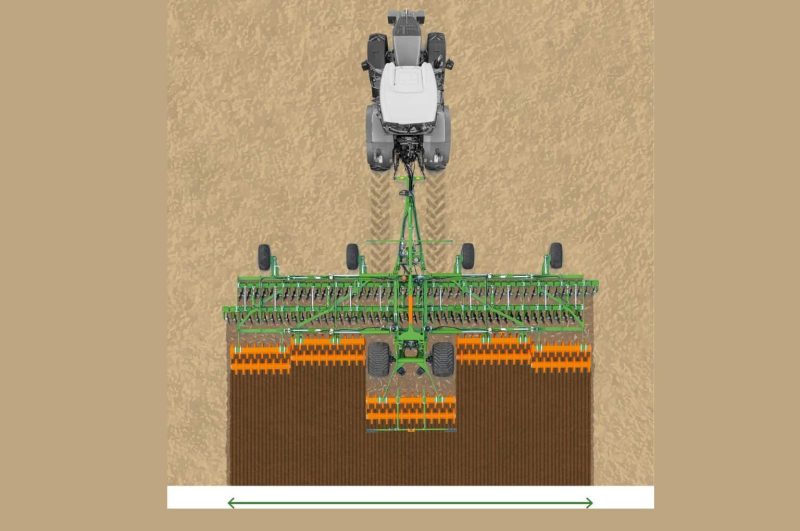

To meet this challenge, Amazone is presenting AutoLane, an innovative system that compensates for the slope drift of compact disc harrows and compensates for double passes and missed areas on slopes and in varying soil conditions. The offset of the trailed compact disc harrow to the tractor is constantly measured by an angle sensor and is processed in the AmaTron 4 ISOBUS terminal. The inclination of the disc harrow on hilly terrain is assessed by a gyroscope to generate an active position measurement.

Based on a known line that mirrors the drift on the slope, a target angle between the tractor and disc harrow is determined and set by the system. Deviation from the target angle triggers the rear row of discs to shift, which results in the disc harrow being pushed uphill in the opposite direction if it drifts downhill. If the working depth of the rear rows is increased slightly, the disc harrow moves to the left. However, if the working depth of the second row of discs is reduced slightly, the implement pulls to the right.

As a rule, minimal adjustment of a row of discs is sufficient, so that the influence on the working result is negligible. The Amazone SmartFrame enables the rows of discs to be adjusted in relation to each other. The permitted stroke lengths of the adjustment cylinders are limited to maintain the current working depth. The integration of electro-hydraulic components, various bearing sensors and angle sensors and the ISOBUS control system will form the basis for AutoLane on the Catros-2TX disc harrow.