Following the introduction of the Spirit 9200i in 2024, AVR now launches the Spirit 9200i VW. The upgraded machine includes the features of AVR’s most recent trailed harvester, completed with the patented Varioweb (VW) cleaning system.

The Spirit 9200i with features such as improved cleaning modules, intelligence (automated functions) & intuitive ease of use, already offered some important upgrades in the field of control, traction, haulm web and the Clean & Go-bunker.

Now, AVR is adding the Varioweb cleaning system VW, which enables flexible cleaning for the most challenging harvesting conditions.

The machine’s drive system is compatible with ISOBUS, enabling the machine to be configured via the ISOBUS-compatible display screen of choice. AVR offers a Müller Touch800 or Smart570 screen for this purpose. The machine also comes with an ergonomic AVR joystick as a standard, and thanks to the ISOBUS-AUX system, various functions can also be controlled via the tractor joystick.

Clear icons and intuitive menus, supplemented by the automatic functions of the machine, all serve to optimize the user-friendliness of the Spirit 9200i VW.

High sieving capacity, low drop heights

Two or three sieving webs ensure first cleaning and transport the product to the Varioweb module. Either two short digging webs or one long digging web can be attached to the front of the machine. An additional digging web and therefore one more drop, significantly increases the machine’s sieving capacity. If the soil can be sieved easily and for the gentlest treatment, a single long web is the best option.

Drop heights are kept to a minimum throughout the machine. Because the haulm and sieving webs are close to one another, the drop height from the digging to the sieving web is very low.

The Varioweb cleaning module features the combination of a pintle belt and axial rollers. A unique feature is the ability to infinitely adjust the product flow volume that travels across the axial rollers from the tractor cab: from 100% when intensive cleaning is required to fully removing the axial rollers from the product flow when minimal cleaning is required. This is achieved by moving the pintle belt forward or backward.

An ingenious Varioweb belt allows this movement within the limited space. The pintle belt’s side walls and the axial roller set have been coated with stainless steel and/or plastic to keep the amount of soil sticking to it to a minimum.

The pintle belt’s position in the Varioweb is measured and rendered on the tractor display. This also allows to save settings and easily retrieve these later, using presets.

Adequate haulm separation

The primary haulm separation system is a combination of the sieving web and the haulm web. A set comprising two rows of retainers and another set comprising three rows of retainers mounted above the haulm web ensures that the potatoes stay in the machine. These sets are individually adjustable in height, and the rows of retainers have been mounted to ensure an adequate distance in between the rows to optimize the machine’s separation capacity. In the event of an accumulation of haulm, the frames of the rows can be folded upwards.

Optional Clean & Go and hydrostatic drive

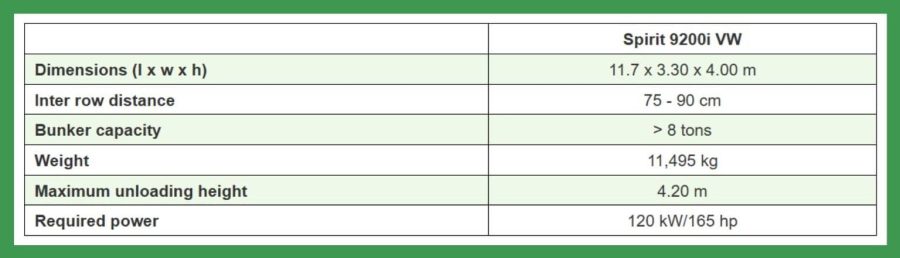

The Spirit 9200i VW is equipped with an 8.5-ton bunker as standard. Unloading height can be adjusted up to 4.20 m, for which a hydraulic collapsible shock absorber or crate-filling funnel is available.

A Clean & Go bunker is also an option. With this, the best of both worlds: an 8 tons potato buffer, additional sieving capacity and the option to unload the bunker while driving.

Hydrostatic wheel drive is available optionally. An additional hydraulic pump drives a 2815cc wheel motor on the right wheel and a 1745cc wheel motor on the left wheel. Consequently, the rear axle is provided with a traction capacity of 120 hp. The traction system, more powerful than in the previous model is user-friendly. It can be operated via an intuitive supplementary keypad, while the ISOBUS control automatically detects whether the machine is moving forwards or backwards.

Digital AVR Connect

The Spirit 9200i VW can be fully monitored remotely, online. An AVR Connect account allows to monitor data in relation to the work performed, sensor data and alarms. Also remote diagnostics are possible for even better support from dealer or AVR. The quick-change digging unit allows to harvest several crops with the same machine.

The Spirit 9200i VW will be on display, fully operational in a demo set-up at the Potato Europe trade fair on 3 and 4 September in Lelystad, The Netherlands.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)