Claas launches the new Jaguar 1000 series self-propelled forage harvesters with throughput capacities of up to 500 tonnes per hour. The series includes four new models with engine outputs, from 850 to 1,110 hp and a new generation Pick Up and Orbis headers.

The Jaguar has been on the market for over 50 years. These many years of experience, development and practical field tests, have resulted in the design of the new series. The Jaguar 1000 includes a wider crop flow, fully hydraulic pre-compression, homogeneous chop quality, large corn cracker drive, drive concept with two independent variable front attachment drives, new high-throughput Pick Up and Orbis front attachments, driver assistance systems, maximum comfort, contemporary connectivity, new Nutrimeter and a strong chassis with a high-traction and ground-protecting drive.

Fully hydraulic pre-compression

Short cutting lengths and difficult harvesting conditions with tough crops, pose a challenge for the crop flow of forage harvesters. With this in mind, Claas developed the widest crop flow channel in conjunction with a new pre-compression system. The four pre-compression rollers work with a fully hydraulic pre-compression system. Thus these enable a uniform crop flow regardless of the layer thickness. This guarantees uniform feeding of the V-Flex chopping cylinder and ensures maximum throughput with homogeneous chop quality and optimum overall efficiency of the machine.

The pre-compression rollers can be raised hydraulically for cleaning work using the maintenance function. The entire pre-compression unit can be swiveled up to 80 degrees for maintenance work in just a few simple steps. The tilting frame with hydraulic centring for Pick Up and Orbis is located on the pre-compression unit.

910 mm wide V-Flex chopping cylinder

The V-Flex chopping cylinder was introduced in 2024 for the Jaguar 900. Thanks to its 910 mm width, V-Flex on the Jaguar 1000 now offers even more space and inertia for maximum throughputs and continuous crop flow, even at the highest swath thicknesses such as in whole crop silage. The crop is cut even more efficiently thanks to the steep knife angle of 10 degrees. This also reduces noise level.

Throughput levels of up to 500 t/h require effective center punching and residual plant processing in silage maize harvesting. The Jaguar 1000 is equipped for this thanks to the Multi Crop Cracker XL. Available either as the MCC XL Classic with a sawtooth profile with various teeth and a 40 per cent speed difference or as the MCC XL Shredlage with a 50 per cent speed difference, it offers a large contact surface between the rollers with a 310 mm roller diameter, ensuring best conditioning across the entire available chop length range and even at the highest throughput capacities.

The chop quality analysis in Claas connect can be used to easily determine the processing score (CSPS Corn Silage Processing Score) via a photo, made by a smartphone in the field and sent directly to the cloud via Claas connect. Within a few minutes, the AI-based program determines the CSPS and transmits the result back to the smartphone. This saves time and enables the optimum setting of the corn cracker for the respective conditions of use as the basis for maximum forage quality and efficiency.

Variable discharge chute concept

The throwing accelerator has also been adapted to the increased output of the Jaguar 1000. Whether for chopping with a wide, concentrated throw or for short transfer distances to transport vehicles travelling alongside: the hydraulically adjustable gap of up to 60 mm by moving the accelerator towards the back panel allows the throw to be adjusted easily and increases the efficiency of the Jaguar.

Also new is the discharge manifold concept. By simply swapping the manifold end piece, the length can be optimized for the respective front attachment from grass to maize and vice versa. The end piece can be folded hydraulically for maize harvesting with Orbis 10500 and maximum manifold length to enable safe road transport.

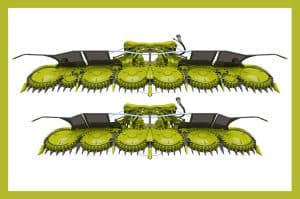

New generation Pick Up and Orbis

The Pick Up 3000, 3800 and the new 4500 with independent variable drive of pick-up and intake auger speed are newly designed. With Cemos Auto Header, the auger and pick-up speeds are automatically adjusted to the length of cut and the driving speeds during harvesting. The models cover working widths of 3.0, 3.80 and 4.50 meter. Instead of chain drives, mechanical power is transmitted via PTO drive shafts and gearboxes. With its constant hydraulic pre-press pressure, the intake auger ensures an even crop flow to the feeder unit. The two cam track gears of the 5-row pick-up are oil-lubricated, encapsulated and therefore operate with low wear. Active Contour control in combination with the swingarm-mounted pick-up ensures optimum ground contour following and thus loss-free harvesting even at high forward speeds.

In maize harvesting, the new Orbis headers reach working widths of 9.00 m and 10.50 m (12 and 14 rows). Another new feature here is the independent variable drive of the knife and transport discs as well as the feed drums for the best chopping quality in all harvesting conditions and lengths of cut. From the comfort of the cab, the operator can use Cemos Auto Header to adjust the speeds of the crop flow elements in harvesting mode to the length of cut and the driving speeds.

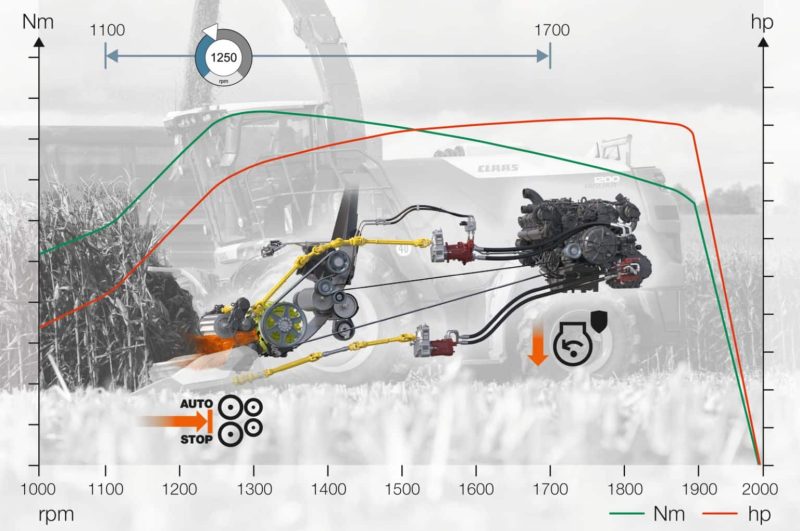

Efficient and variable drive concept

Since 1994, transversely mounted engines in the Jaguar have been driving the knife drum and other units directly and therefore with particularly low losses. In the Jaguar 1000, too, a powerband takes the power directly from the crankshaft of the MAN 24-litre V12 engine and transfers it to the chopping cylinder, throwing accelerator and from there to the corn cracker. For the ground drive, the pre-compression rollers and the two independent variable attachment drives, a pump transfer case is located at the rear left of the engine, which drives the hydraulic motors. Thanks to the independent variable attachment drives, the pick-up and intake auger on the Pick Up and the knife and transport discs and feed drums on the Orbis can be adjusted independently of each other in terms of speed to suit the harvesting conditions.

The Jaguar 1000 comes with 4-wheel drive and all-wheel management as standard. Differential locks on the front axle and on the rear axle are also offered as an option, as is a tyre pressure control system for the front and rear axles. The drive design allows for 800/70 R42 front axle tires with a total machine width of 3.30 m, with the largest possible front axle tire for the Jaguar 1000 being 900/60 R42 with an outer diameter of 2.15 m. In addition, tires up to 710/60 R30 can be selected for the rear axle.

Cemos as standard

The Jaguar 1000 is equipped with Cemos Auto Crop Flow and Cemos Auto Performance for consistently optimum overall efficiency with maximum driver relief. The Cemos Auto Performance engine and drive management system relieves the operator and ensures a constant or maximum throughput throughout the harvest by adjusting the driving speed to the engine load, and automatically adjusts the engine power if necessary, for example when yield levels are low. This means that the Jaguar 1000 always works in the optimum power range and reduces fuel consumption. Cemos Auto Crop Flow intelligently and automatically monitors the engine speed at all times to ensure that the forage harvester is operating correctly and stops the crop flow if the engine speed drops below the set minimum speed.

During operation, the operator is also relieved by Auto Fill. With the help of digital 3D image analysis via the corresponding camera technology, the discharge spout and flap control for filling transport vehicles travelling alongside is carried out automatically – both day and night.

Real time chop length adjustment

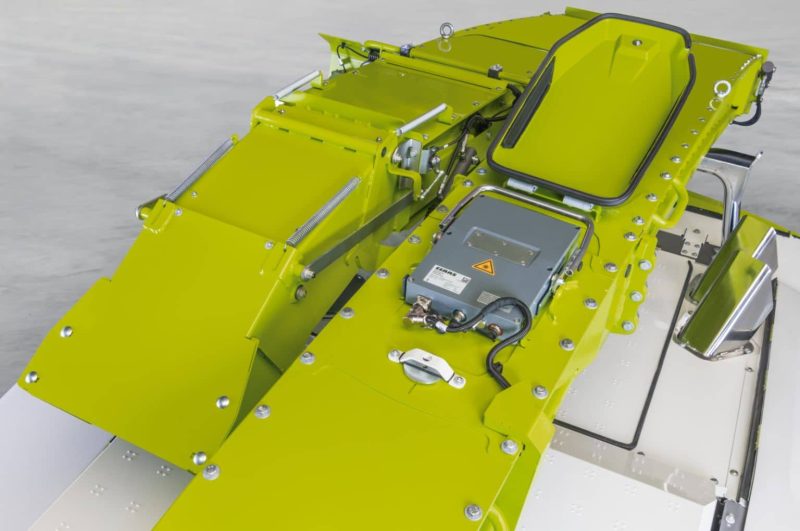

The Jaguar 1000 comes with the latest generation of the NIR sensor Nutrimeter. Thanks to precise real-time determination of the dry matter content, it enables precise yield recording and yield mapping, as well as automatic chop length adjustment. This supports the best forage quality depending on the dry matter content and optimum compaction of the silage in the silo.

In addition to dry matter content, the Nutrimeter also records other ingredients such as starch, crude protein and sugar content. A new feature is the mobile use of the NIR sensor as an ISOBUS device, which enables easy conversion from machine to machine. The data collected by the Nutrimeter is stored, analysed and output together with the machine data from the Jaguar in Claas connect.

Quieter and more comfortable cab

The spacious upgraded cab is operated as usual, using familiar controls such as the Cmotion ground speed control lever in the right-hand armrest console, as well as the integrated Cebis terminal with its 12 inch screen. The GPS Pilot Cemis 1200 is available for satellite-supported steering and smart farming tasks such as vehicle fleet and order management as well as documentation. Various seat variants, including a swiveling leather seat – available with seat heater and seat ventilation -, automatic air conditioning and low noise level in the cab ensure a comfortable and fatigue-free working environment.

A first for Claas harvesting machinery is the optional joystick steering, enabling tight turning manoeuvres at the end of the field. It has two steering modes and can be customized in various intensity levels. In addition, three switches are integrated into the armrest for individually assignable functions, such as lowering and raising the discharge spout, the horn or the work lighting. In addition to the satellite-based GPS Pilot Cemis 1200, other automatic steering systems are available, such as Auto Pilot and Cam Pilot.

Fully networked with farm and cloud

Claas connect seamlessly integrates machine and farm management. Important Jaguar 1000 data such as fields, reference lines, operating resources, machines and labor can be recorded, analyzed and optimized. Users have an overview of their machines, and can compare them, both in terms of work performance and. In addition, yield maps can be quickly and easily used to create application maps. With the mobile Claas connect app, all information is always available, even when you’re on the move. From 2026, live yield mapping will also be available on the Cemis 1200. This allows yield and moisture to be displayed live on the CEMIS display as a map during harvest.

With the Cemis 1200 and a Machine connect license, job management for the Jaguar 1000 is done in just a few clicks via the mobile phone connection and yield maps can be created live. Jobs, including reference tracks, can be planned in advance in Claas connect and transferred to the machine. For example, GPS Pilot Cemis 1200 can steer the Jaguar months later with centimeter precision using the tracks from the maize sowing. After completing the job, the operator quickly and easily sends the collected machine data, including yield data, back to the office. From the order to its execution and documentation, data processing is largely automated and therefore simple and secure.

Market introduction

The world premiere of the Jaguar 1000 is in California USA and will be followed by further customer and media events in European fields during September, just in time for the maize silage harvest. In addition, the new forage harvester series will be one of the highlights on the Claas stand at the upcoming Agritechnica trade fair from 9 to 15 November in Hanover, Germany. Series production of the Jaguar 1000 will start in autumn 2025.