John Deere launches its new F8 and F9 Series self-propelled forage harvesters. These machines are designed to deliver improved driving experience, combined with advanced automation and precision farming technology. Moreover, the F8 and F9 Series deliver further enhanced silage quality.

Major feature of the new machines is the cab which is wider and more comfortable. The optional electric door closer ensures a good seal. Inside the cab, storage solutions allow users to find room for their items, such as dedicated holders for smartphones, keys and beverages. The infotainment system includes Bluetooth connectivity. Charging options, including 12V and USB ports, are available for all power needs. Smartphone integration with Apple CarPlay and Android Auto allows for access to calls, messages, music, and voice commands.

The ActiveSeat in the F8 and F9 series swivels 16° to the right and to the left for easy access and maximum visibility. The optional ActiveSeat II also offers fully adjustable electric controls, cooling/heating, a massage function, and active suspension technology that isolates up to 90% of vertical movements for a smooth ride. The slim cab pillars and sweeping windows provide panoramic visibility from the header to the flap of the spout. The spout now can be rotated up to 230° for optimal unloading while the redesigned steering system of the rear axle delivers an impressive 6 m turning radius for faster headland turns.

Machine control and harvesting settings

The F8 and F9 are equipped with intuitive controls for machine and harvesting settings to enhance user experience. Machine settings can be stored in different driver profiles, allowing for a quick start of harvesting without the need to adjust settings with every change of driver.

The new ergonomic CommandPRO joystick features up to 11 customizable buttons. It is easily programmed via the touchscreen of the G5/G5Plus CommandCenter display. This includes settings for header folding, spout lift, AutoTrac, ProTouch, Machine Sync, 4WD and more.

The G5/G5Plus CommandCenter touchscreen display with shortcuts and context-sensitive help simplifies navigation. A new forage harvester specific screen menu allows operators to quickly adjust the most relevant machine functions by one fingertip. It is 35% larger and 75% faster than previous displays, with a high definition 1080P screen. An optional G5Plus Extended Monitor doubles the 12.8” screen, allowing users to monitor more functions simultaneously and make adjustments as needed. Essential data is displayed via info graphics on easy-to-read screens on the corner post display.

“With the F8 and F9, we’ve reimagined the entire operator’s environment to deliver maximum comfort and intuitive control. It has been built around the operator,” says Philippe Steinmann, Go to Market Manager Europe at John Deere.

More engine power

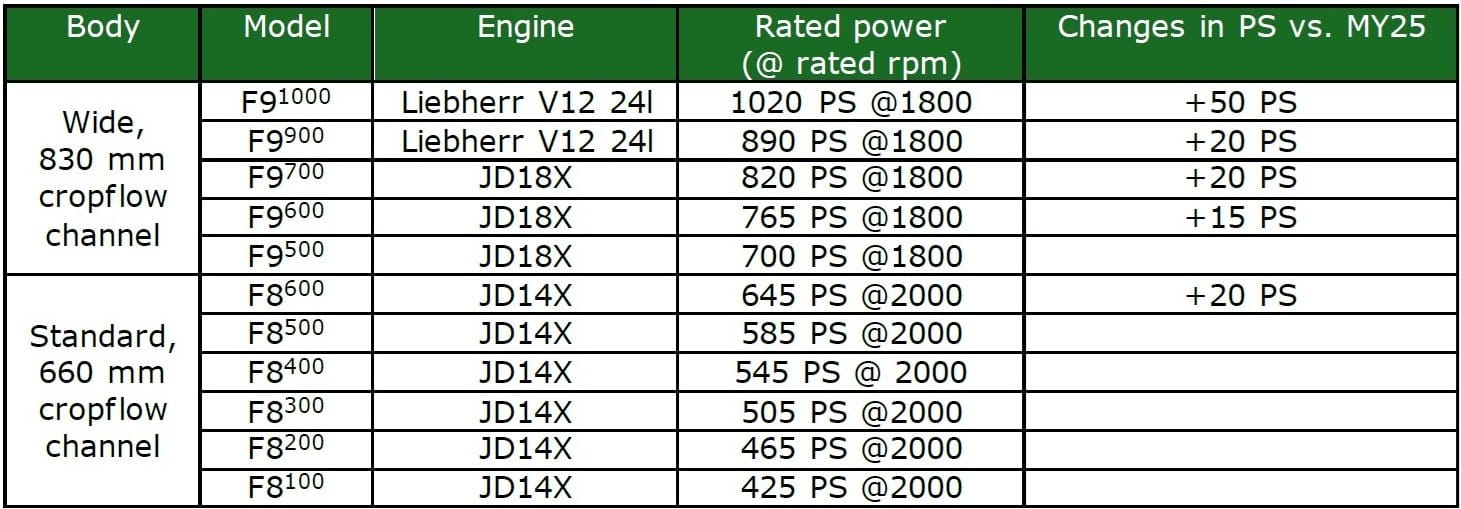

The F8 and F9 forage harvesters offer various engine options to meet different needs. The JD14X engine now powers all six F8 models, meeting Stage V emission standards. The engine power range (rated , ECE R120) starts at 425 PS (313 kW) with the F8 100 model and the new top model F8 600 delivering 645 PS (475 kW). HarvestMotion technology maximizes productivity at reduced engine speeds, delivering constant power over a wide rpm range. Engine speed management improves fuel efficiency by reducing engine rpm during transport and at headlands.

In the F9 series (models F9 500 to F9 700), the JD18X engine in the rated PS range from 700 PS (515 kW) to 820 PS (603 kW). It features John Deere engine controls, a high-pressure common-rail fuel system, and serial turbochargers with cooled exhaust gas recirculation (EGR) and no need for diesel exhaust fluid (DEF). All JD18X engine models feature HarvestMotion Plus technology.

The third engine option, the Liebherr 24.2L V12, powers the F9 900 and 1000 models, delivering up to 1020 PS (750 kW, rated). Again, these models also feature HarvestMotion for best productivity and driveability at maximum throughput.

Advanced technology stack

Ground Speed Automation on the F8 and F9 optimizes automatically vehicle speed and engine rpm, based on engine load and preselected target speeds and engine loads. Active Fill Control utilizes a stereo camera system to control the rotation and flap position of the spout automatically, tracking transport vehicles and aiming the crop for optimal fill strategy. The ProTouch harvest system offers single-click headland automation for maize, grass, or whole crop silage, managing header lift, spout control, AutoTrac, Active Fill Control, and Ground Speed Automation for easy headland turns. When switching between road and field, the ProTouch technology handles up to nine essential functions, including beacon lights, 4WD, settings for engine speed management, and spout positioning. John Deere Precision Ag Technology options, such as AutoPath (rows and boundaries) can be added optionally.

“The F8 and F9 can be equipped with advanced automation and John Deere precision ag technology”, Steinmann explains. “From ground speed automation to intelligent crop tracking or ProTouch Harvest, these features help operators to focus on the harvesting job, achieving both efficiency and forage quality.”

Silage quality further improved

The well-known DuraDrum cutterhead performs with remarkable flexibility for various harvesting requirements. The new inoculant dosing system, IDS 2.0, works with HarvestLab sensor readings to optimise silage quality. The system features a 50 l insulated concentrate tank for highly concentrated additives, as well as a 325 l tank for high volume application as well as for water. Furthermore, the engineers integrated a cleaning system including a clear water tank. John Deere also offers two new advanced kernel processor options. For one, the John Deere Ultimate 250 kernel processor with larger 250 mm rolls, temperature monitoring and foldable design for best serviceability. Secondly, the John Deere XStream 305 kernel processor delivers a 56% larger surface with 305mm rolls, electrical adjusting and the well-proven oil-mist greasing for best processing in all length of cuts.