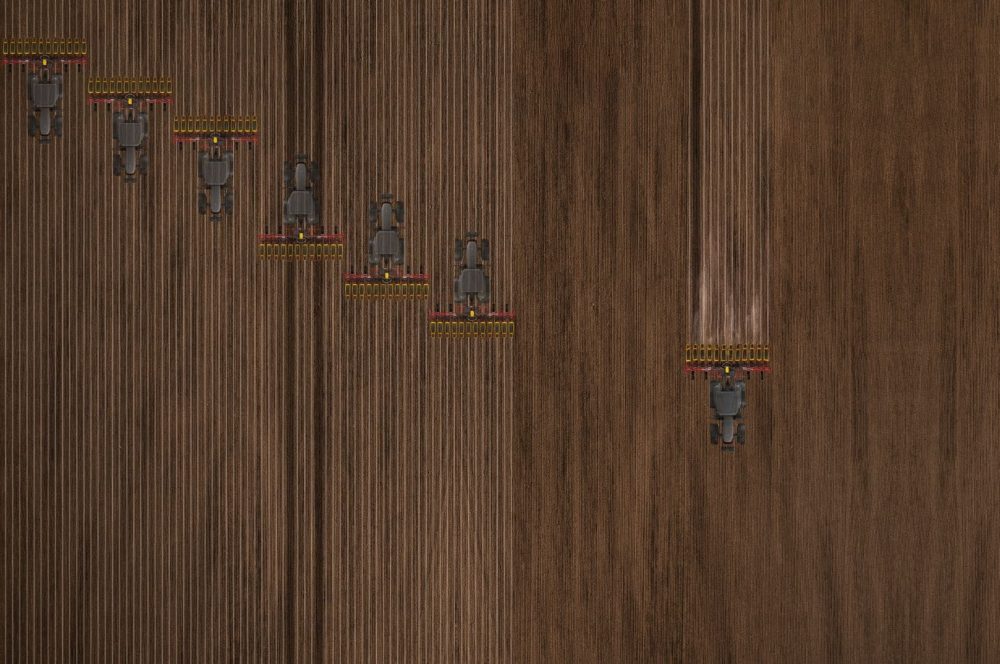

ISOBUS Dynamic Tramlining is easy to set up with the iPad-based control system Väderstad E-Control. When in the field, the machine automatically shuts off specific rows when needed to match the tyre tracks of the sprayer. The tramlining will be controlled automatically, shutting off the rows independently of where they are on the machine.

“The main benefit of ISOBUS Dynamic Tramlining is its ability to function seamlessly, even when the farmer is not planting the field in adjacent tracks. The GPS signal ensures that tramlines are created accurately, regardless of the planting pattern”, says Oskar Karlsson, product manager for planters at Väderstad.

ISOBUS Dynamic Tramlining works together with additional tramlining options for the Tempo range. These include WideLining for Tempo V, as well as active hydraulic downforce for Tempo F, Tempo V, Tempo L and Tempo K.

“When combined with the individual active hydraulic downforce system, the planter not only shuts off the seed output for the tramlines but also lifts the row units out of the soil. This creates clear, undisturbed tramlines that are visible even before the crop has emerged”, Oskar Karlsson adds.

ISOBUS Dynamic Tramlining is available for all Tempo planters, as well as Proceed V 24 from model year 2025. In addition, it can be equipped to current Tempo machines by upgrading to the new generation Gateway. This change will also make additional features available, such as an easier task control connection, programmable tractor joystick buttons via ISOBUS Aux-N, as well as an updated user interface for the Väderstad machine on the tractor terminal.

The Väderstad machine relies on the tractor ISOBUS screen to be compatible and unlocked with the ISOBUS Tramline feature. This is currently seen on several newer terminals on the market.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)