“Today’s global market increasingly demands high-tech tractors”, says Argo Tractors Engineering Director Massimiliano Del Bue. “Through our substantial R&D investment and with the help of our cohesive team, a youthful environment, qualified staff and constant training, we are prepared to take on this challenge.”

For nearly 25 years the McCormick brand has been part of the Argo Tractors family, the industrial group based in Fabbrico, Italy. Argo Tractors maintains strong roots in the Emilia Motor Valley, a project to enhance, protect and develop the regional motoring tradition, of which Argo Tractors has formed a part since 2022.

“With its range of tractors at the forefront of this category in terms of technology, power, comfort and safety, and with all the strengths of its American origins, McCormick has positioned itself as the Argo high-performance brand, capable of meeting the global performance expectations”, explains Massimiliano Del Bue. “McCormick’s growth comes through a constant commitment to renewal, product consolidation and innovation”.

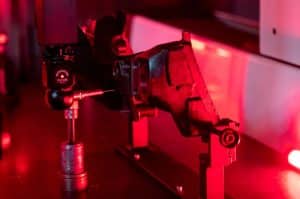

The Argo Tractors Group constantly invests almost 6% of its annual turnover in Research & Development and today employs around 160 technicians. The continual training of staff, constant technological renewal of design, testing and simulation facilities allows the company to achieve and maintain the quality standard of its product.

“Today’s tractors are the result of an articulated process of technologies in various engineering departments”, continues Massimiliano. “It is not just about mechanics and hydraulics, but vehicle dynamics, software and controls also play a key role, right down to the extreme attention to design and styling details. We live in a world of energy and technical transition, in which we have to compete with a rich, increasingly sophisticated and diversified product range. We can no longer rely on the creativity of individual contributors to achieve all our goals. All product development must increasingly be a team effort”.

Dedicated testing

A team of specialised engineers is in charge of the test areas, from the hydraulic unit and transmission to engine integration, and carries out the tractor performance tests on the bench and mainly in the field. The team basically carries out the important work of data collection and troubleshooting, contributing to the development of new products”.

The group has more than 30 people, coordinated by 2 team leaders and 10 engineers, involved in product improvement activities, from specialized models to compact and utility tractors, and concluding with the high-power range. Given the variety of models, a methodological approach is required, with dedicated testing and periodic updating of standards, with monitoring criteria guided by remote diagnostics and telematics systems.

“My role”, resumes Massimiliano Del Bue, “is to enhance and channel the flow of information, so that the project develops in synergetic sections. The team that has been created over the years is very cohesive and you can feel the passion that drives us to improve every day. A youthful environment has developed in which many new engineers come directly from the Universities of Bologna, Modena and Reggio Emilia, and beyond”.

Technological hub

Argo Tractors has in recent years created the McCormick Digital Solutions, a technological system that constantly monitors work, tractors, remote diagnostics, fields, crops and the farm itself. The tractor becomes a technological hub where all the necessary information is collected, channeled and made available to the farm.

An increasingly important role in the technological process is assumed by electronics, as the head of the Electronic Department argues: “In a McCormick tractor there are more than 10 electronic control units, which manage the mechanical and hydraulic elements. Another significant aspect is the HMI technologies, e.g. headland management, which allow the operator to interact easily with the complex work station system. The latest innovations and market challenges include reducing the environmental impact of agricultural operations, increasing productivity and reducing the operating and maintenance costs of tractors. Challenges taken up by Argo Tractors with the launch of numerous projects, from the study of innovative hybrid and electronic propulsion systems to the implementation of Industry 4.0 systems, which allow the vehicle to be monitored remotely”.