Rometron, specialist in precision spraying, is celebrating its 25th anniversary. The company gains its reputation from innovative technologies. Most significant product is the advanced WEED-IT spraying technology for weed control, through chlorophyll detection.

With a quarter-century of experience, Rometron has set a new standard in precision spraying. Founder and CEO Roel de Jonge began 25 years ago from Wageningen University & Research (WUR) with an idea that has grown into what Rometron is today: a high-tech producer in smart farming technology. By continuously investing in new technologies and integrating hardware, software, data, and practical experience, Rometron continues to develop the next generation precision spraying technology.

Roel de Jonge started Rometron 25 years ago. Nowadays the company is a global player in precision spraying technology

Leading product developed by Rometron is WEED-IT, utilizing optical sensors and spraying technology to accurately detect and spray weeds. This ensures that crops remain untouched and yields are maximized, while reducing environmental impact. With 2,000 operational installations worldwide, spanning markets in Australia, South America, North America, and South Africa, WEED-IT saves 30 million liters of undiluted herbicides annually.

Focus on Research & Development

Rometron has significantly expanded its R&D department, tripling the number of software and hardware engineers. This has led to continuous innovation, such as the development of new detection sensors with a target of 95% detection accuracy. Additionally, Rometron will introduce new features later this year to further enhance the functionalities of the WEED-IT system. These innovations are designed to provide customers with even more precision and efficiency in weed management.

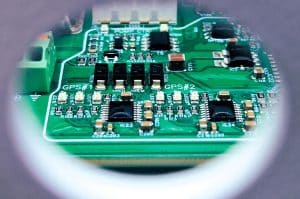

A recent highlight is the installation of a “Surface Mounted Device” (SMD) production line. It enables self-developed sensor PCBs to be equipped with over 900 electronic components per sensor. Rometron has invested in high-end cable production machines, including an automatic cut-strip-crimp line. By keeping production in-house and continuously training production staff, Rometron ensures optimal quality assurance and a high-quality end product. The expansion of production capacity is crucial to keep pace with the growing demand for precision agriculture technologies. With all the expansions in personnel, production machines, and floor space, Rometron can ensure a global saving of 60 million liters of undiluted herbicides per year.

Rometron aims to help farmers worldwide optimize their weed control, resulting in healthier soil and reduced chemical usage. This contributes to higher crop yields and more sustainable agriculture.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)