Trioliet, supplier of feeding and weighing systems, recently commissioned a new, energy-efficient powder coating plant. This plant has significantly more capacity while using around 40% less energy, compared to the previous plant. By applying an upgraded pre-treatment technique to the steel, this boosts corrosion resistance by an additional 30%.

The new powder coating line has only one curing oven instead of the usual two. The conventional gas oven has made way for an energy-efficient infrared oven. A new, specially developed coating allows the second coat to be applied directly after the first, without the need to heat the parts in the intervening period. This eliminates the need for an oven, saving an estimated 75,000m3 of natural gas per year. Hence, faster processing is now possible with less energy.

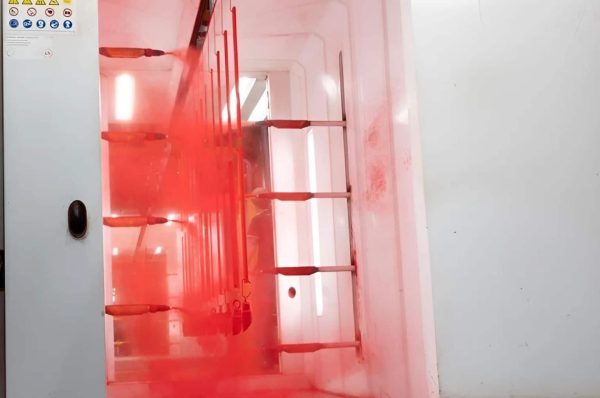

The overhead rail conveyor controls the entire system. Data such as part number, colour, blasting recipe, drying time and moulding time are recorded at each traverse on the transport chain. Furthermore, the blasting and spray booths make use of the solar power generated by 4,400 solar panels mounted on the roof of the production facilities. This allows Trioliet to keep improving the sustainability of its production process.