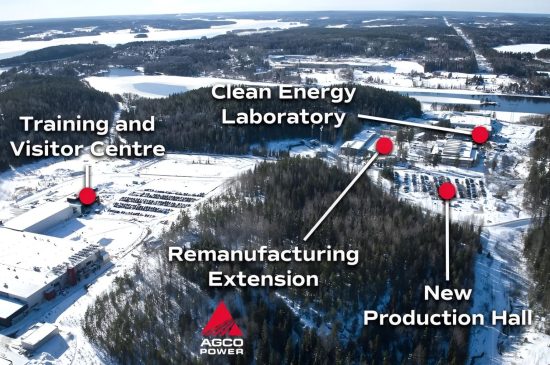

AGCO invests EUR 70 million in its Linnavuori / AGCO Power plant in Nokia, Finland to accelerate further clean energy innovations. The extensive investment will allow the building of a clean energy laboratory to test fuel cells for alternative fuels and select electric drives that will reduce farmers’ fleet emissions.

Improvements also include a training and visitor center, a production hall for machining cylinder heads and manufacturing components for automated Continuously Variable Transmissions (CVTs), a paint shop and testing capabilities for remanufactured engines. The new buildings totaling 11,000 square meters and will be completed throughout 2024 and 2025.

“We are investing in the future of clean energy, Linnavuori and, ultimately, AGCO. By adding production capacity and research capabilities, AGCO Power is building capabilities to better serve our workforce and all farmers who are sustainably feeding the world,” said Juha Tervala, Managing Director of AGCO Power.

The Linnavuori plant employs about 1,000 employees. These investments lay the foundation for future growth. The latest additions illustrate a history of growth in Finland. In November 2023, the President of the Republic of Finland Sauli Niinistö recognized both AGCO Power and AGCO’s Valtra brand, operating from Suolahti, with a long-term investment award. AGCO’s investments in the Linnavuori plant operations have totaled more than EUR 100 million over the past five years.

Testing new technology

In addition to diesel engines, AGCO is expanding its product technology portfolio by developing engines utilizing alternative fuels and various electrical solutions that reduce emissions. The new research laboratory in Linnavuori is a natural extension of AGCO Power’s product development responsibility.

“The clean energy laboratory will house several cells for testing the combustion engines running on alternative fuels, as well as a range of electric solutions, such as hybrids, fuel cells and high-voltage battery technology,” said Mr. Tervala.

Value and life of AGCO Power products can be extended after years of heavy use through remanufacturing. Restoring engines to a like-new state goes well beyond repair. Remanufactured products are stripped down to their individual components, inspected, cleaned and fully rebuilt. The improvements in reman testing capabilities in Linnavuori are part of AGCO’s global investments in remanufacturing.

“We have remanufactured used engines toward a circular economy since 1990. The product improvements are based on the latest revision, and the repaired, tested and painted engine is granted a full factory warranty. The investments in our Linnavuori plant will allow us to grow our reman capabilities to serve global customers,” continued Mr. Tervala.

Growth in machining volumes

AGCO is centralizing its transmission components’ manufacturing operations in Linnavuori. The investments will now allow the facility to expand the manufacturing of CVT components for AGCO’s tractor brands with plans to produce more high precision transmission components in this location. The new production hall will also house a new machining line with a high degree of automation for manufacturing the cylinder heads of AGCO Power CORE engines.

“Currently, we produce approximately one million gear wheels and axles annually, but this number is expected to double after the investments,” Mr. Tervala concludes.