Precision Planting manufactures retrofit solutions in the field of precision farming. The AGCO subsidiary from Tremont, Illinois, USA, helps to increase efficiency and productivity, while promoting sustainable practices. By using latest technologies, data analysis and machine learning, farmers are able to sow more precisely and make better use of their resources, regardless their machine brand.

The portfolio includes a wide range of retrofit products and solutions, including retrofit tools for precise planting depth, optimal downforce and perfect furrow closure. Accurate seeding ensures uniform emergence for better crop yields. By precisely placing seeds and fertilizer, farmers can conserve resources such as water, fertilizer and crop protection while increasing yields. In this way, Precision Planting actively promotes a responsible approach to the environment. Precision Planting offers retrofit tools not only for planters, but also solutions for grain drills, SideDressBars, combine harvesters and sprayers.

Adjusting downforce automatically

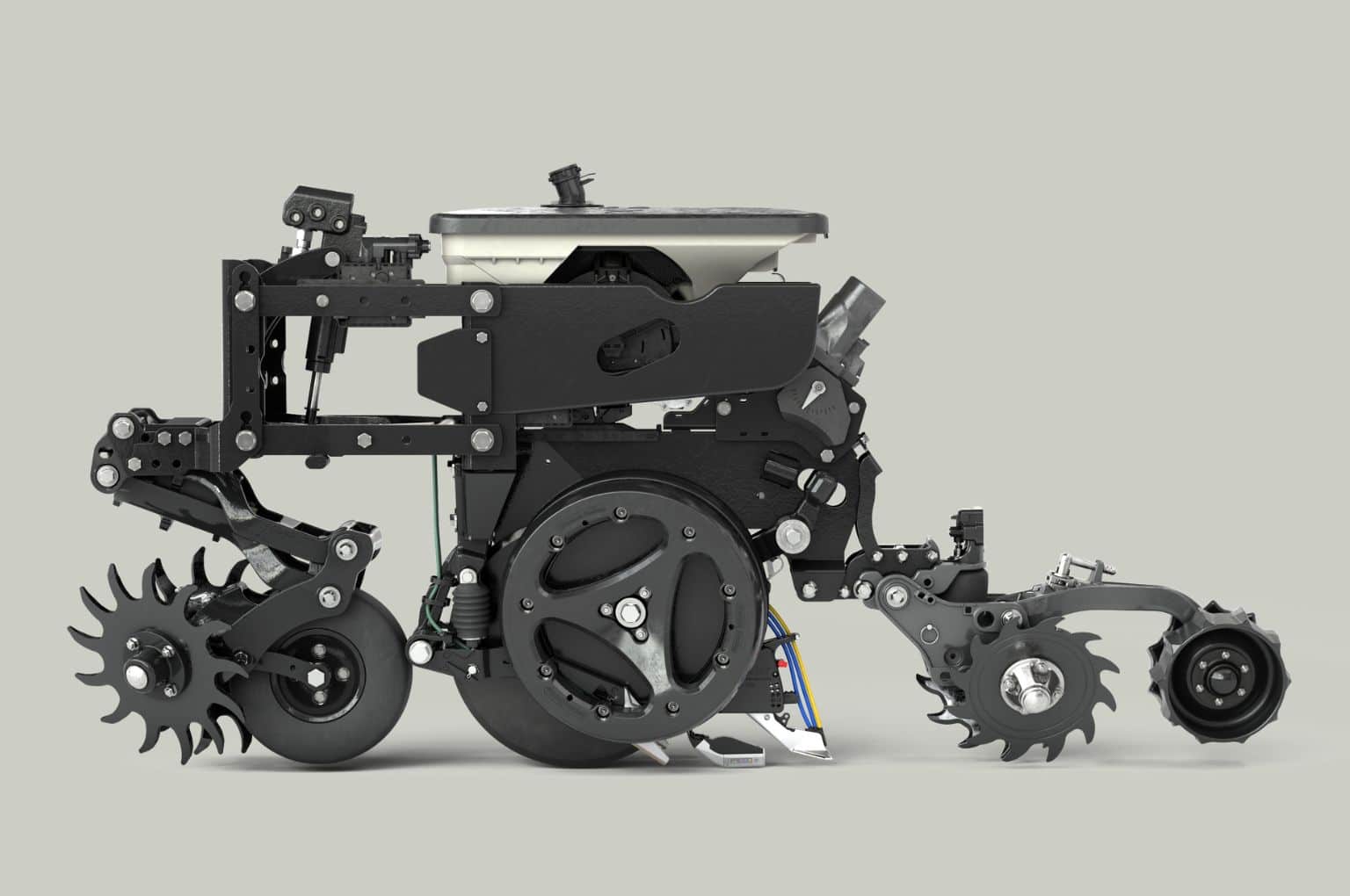

The aim is to make emergence more uniform and to optimize the technical equipment. One example of this is the DeltaForce automatic down force system, which measures and regulates the down force row by row and several times per second to ensure optimum placement depth and root development. A fixed down force setting is rarely suitable for all conditions of a field, as many farm areas are heterogeneous. Management is therefore a balancing act between “not too much and not too little”. Too little downforce causes shallower placed seeds and late germination. Too much on the other hand, leads to compaction and poor root development – both of which cost yields. To ensure that the down force setting is suitable for all areas, it is first measured and then adjusted accordingly.

The automatic DeltaForce downforce system was developed for this purpose. It measures and regulates the downforce during sowing, row by row and several times per second. The system detects, visualizes and adjusts machine settings in real time based on the data collected. Depending on the conditions, the individual units can be pressurized or raised individually. This minimizes the risk and lays the foundation for uniform field emergence.

“We are proud that our technologies and solutions are helping farmers agriculture to a higher level. We want to make a decisive contribution to promoting productivity and sustainability in agriculture,” confirms Thorsten Sütterlin of Precision Planting.

Rethinking sampling

Reliable soil data is essential. There are many different soil scanners, but they often deliver different results. Therefore, wet chemical soil analysis is still necessary, be it just to calibrate the scanner methods, drone or satellite data. A cost-effective, standardized laboratory method that allows a high number of samples per hectare would give precision agriculture a boost in this respect.

With Radicle Agronomics, a system is now available that combines planning, sampling, analysis and the entire logistics of soil sampling. There is no need to create labels and label soil bags. All this is done automatically in the field while GeoPress fills the GeoTubes with the collected soil. With the help of RFID technology, each sample container, a so-called tube, is provided with the coordinates and the data required for further processing in the laboratory. On an area of 3×3 meters, the Radicle Lab soil laboratory included in the system then carries out all the necessary work such as calibration, preparation, analysis and reporting fully automatically within a few minutes. Only the tubes need to be placed on a shelf manually. The software seamlessly integrates sampling, charting and analysis into a single platform.

Radicle Agronomics represents a significant advancement in soil sampling. Winner of the silver medal at the recently held Agritechnica trade fair in Germany, the system enables rapid and accurate delivery of soil sampling results to make informed decisions for crop planning.