With the Pantera 7004, Amazone is offering a further model in the self-propelled sprayer segment. Features of this new machine are its high tank capacity and the newly developed running gear. The Pantera 7004 combines high performance with modern driving characteristics. It is designed for large-scale farming.

With a maximum spray tank capacity of 7,000 l and a nominal volume of 6,600 l, the Pantera is designed for enormous work rates. The tank is made of glass-fibre reinforced plastic and has smooth inner and outer walls with no nooks and crannies, which allows perfect cleaning. The layout of the four high-pressure cleaning nozzles, agitation and outlet sump is based on the tried-and-tested concept of the existing Pantera models and guarantees optimum cleaning with minimal residual volumes. A 500 l tank provides fresh water for cleaning. This is positioned at the rear of the machine ensuring that it has a low centre of gravity, even with an empty spray tank.

High-capacity lightweight

The machine is lightweight in its performance class with an empty weight of approximately 12 t. Large wheels with an outer diameter of up to 2.05 m can be configured for maximum soil protection and clearance. Furthermore, an optimum weight distribution and automatic traction control on each wheel guarantee the best possible traction in any situation.

The drive is tailored to the operating conditions with an engine power of 306 hp (225 kW), which is hydraulically transferred to the wheels. The Pantera can therefore work under any conditions.

Independent wheel suspension and slope compensation

The hydro-pneumatic suspension is adaptive, whereby the characteristics of the running gear are tailored to the driving situation. This intelligent control provides the best driving stability and maximum driving comfort combined with a simple and weight-reduced design in comparison with a conventional independent suspension. In addition, the system prevents any rocking when the tank is not completely full and enables high driving speeds, even on poor quality roads. Hydraulic track width adjustment, with a standard track width from 2.00 m to 2.75 m, is fitted as standard. The Pantera-W, with track widths from 2.25 m to 3.00 m, is also available. The ground clearance in both machines is approximately 1.30 m, which means that tall crops can be driven through without damage.

Another point is the soil-conserving function of the offset track driving, in which, for example, the front wheels can be set at the minimum track width and the rear wheels at maximum, meaning the soil is travelled over just once. As a result, especially in unfavourable soil conditions, the soil is not smeared as much and young plants suffer hardly any damage. In contrast to dog-leg steering, the machine is always aligned to the direction of travel.

Integrated slope compensation is another feature. The inclination of the vehicle is detected via sensors and the machine is automatically kept horizontal up to a certain gradient.

This feature, in combination with the low centre of gravity of the machine and the hydro-pneumatic running gear, provides extremely high slope stability. In addition to the enhanced driving comfort, this enables the driver to work safely, even in very hilly terrain.

New comfort cab

The new cab offers a modern work place with all-round visibility. It is equipped with filtration which meets the Cat. 4 standard offering the highest possible safety in the work place. The new armrest is characterised by a clear and ergonomic design. It is tailored specifically to the functionality of a self-propelled sprayer, and all the important functions are always within reach. As part of the twin terminal strategy, the 7″ AmaDrive terminal is responsible for the operation of the base vehicle, whereas the spraying system is operated via an ISOBUS terminal. All the important spraying functions can also be freely assigned to the buttons of the ISOBUS-compatible drive lever.

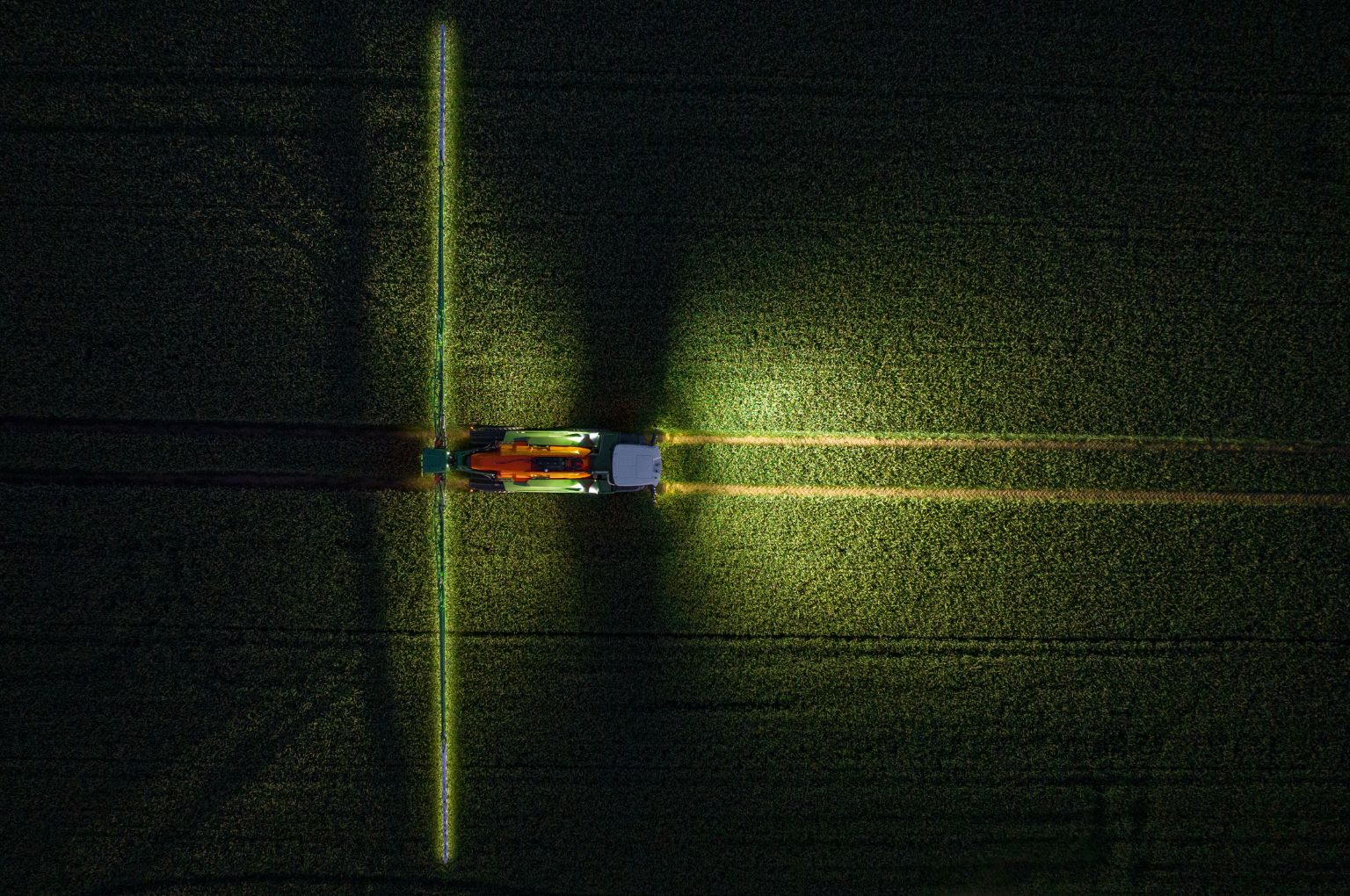

12 LED work lights are now incorporated in the cab roof as standard. Night turns to day in conjunction with the LED work lights at the rear of the machine and the option of individual nozzle lighting on the boom.

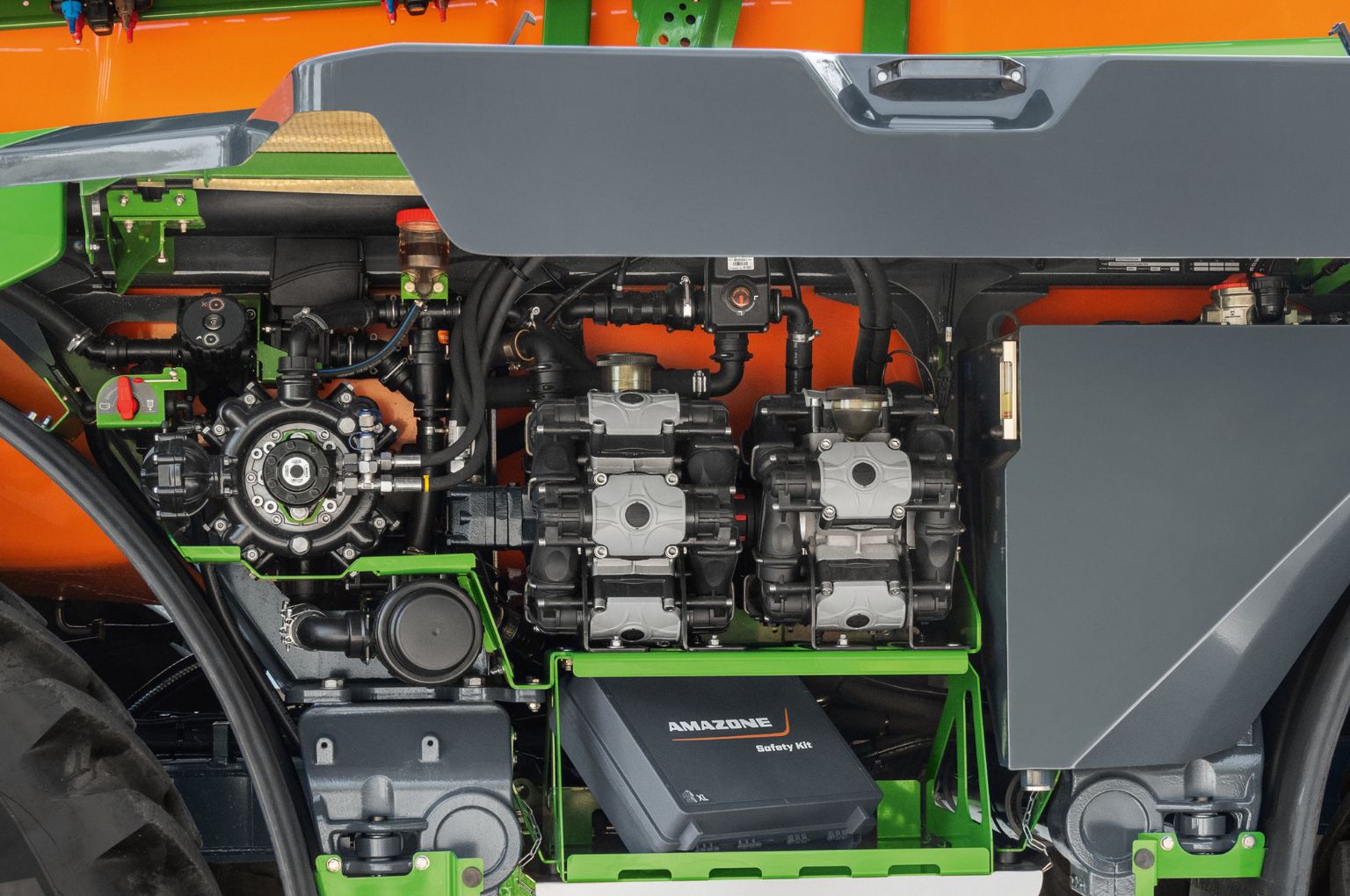

High-output crop protection technology

The piston diaphragm pumps are designed for a constant total output of 610 l/min for maximum work rates. The injection principle provides a suction capacity of approximately 700 l/min for filling. A bowser fill port is available as an option. This allows a filling speed of up to 1,000 l/min with the 3″ line, which results in minimal downtimes.

The SmartCenter is available in the two established variants “Comfort-Pack” and “Comfort-Pack plus” and is sure to impress with operational comfort and performance levels for the induction of plant protection agents.

The precision boom technology with aircraft wing design enables working widths from 24 m to 48 m with many reduction options and a very low weight. Furthermore, high working speeds are possible without having to make any compromise in the application quality thanks to the quick and precise “ContourControl” active boom guidance.

DirectInject direct feed system

The DLG award-winning DirectInject system is available as an option. This enables additional products to be added as and when required in a matter of seconds, which makes the use of the self-propelled sprayer even more flexible and more efficient. The system is fully integrated in the liquid circuit and the operating system of the Pantera, meaning that all the functions – from activation to cleaning – can be started from the cab at the touch of a button.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)