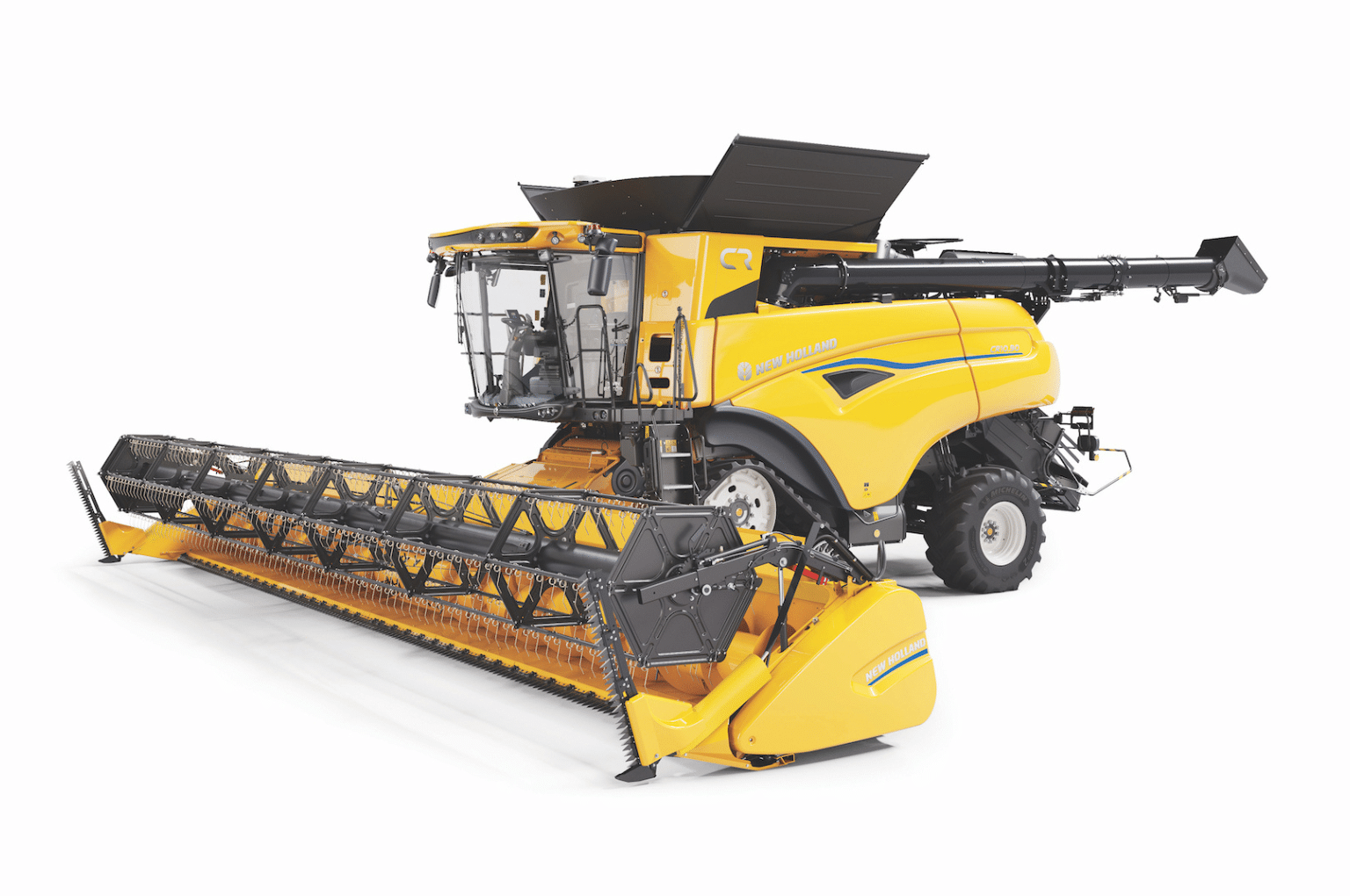

The CR series combine portfolio from New Holland Agriculture is receiving a refreshed look and feel in the next lineup of 2024 models in North America. Enhancements to the design and functionality of the combines, including new seats, cameras, sensors and technology options, showcase the new CR models for North American farmers.

“New Holland recognizes the number of hours operators spend in the cab, and the changes we have made to the CR combine portfolio drive comfort and productivity into our customers’ hands,” says Curtis Hillen, combine marketing manager for New Holland Agriculture North America. “By offering comfort, ease of use and more real-time data insights, we aim to equip farmers with the tools they need to succeed in today’s dynamic landscape.”

The CR series combine portfolio consists of five models: the CR7.80, CR7.90, CR8.90, CR9.90 and CR10.90. The power ratings, basic specifications and harvesting performance will remain the same on all five models compared to prior years, however, a variety of upgrades are coming to the CR combine harvester models for Model Year 2024.

New Holland signature styling

The updated CR combines will now feature New Holland signature styling to align this lineup with other members of the New Holland portfolio and reflect the brand’s commitment to modern aesthetics and the appearance of machines. The refreshed design is easily recognizable with the 3D New Holland leaf decal, New Holland blue details and the CR logo on the graintank.

Two new seat offerings

To further elevate operator comfort and well-being during long hours in the field, New Holland is offering the choice of a premium full leather seat or a deluxe cut and sewn seat on all models. Seat features that can be selected include two-stage heating and ventilation and side contour pneumatic and lumbar support to promote a more comfortable and productive working environment.

Three-camera option

New Holland has integrated a three-camera option into the updated CR combine models. The camera system provides operators with enhanced visibility around the machine to improve safety and maneuverability during harvesting tasks. The three cameras are located on the rear deck railing, above the hitch, and on the unload tube, and the live shot can be viewed through the IntelliView display.

New air hose storage location

Responding to customer feedback from the field, New Holland has relocated the optional air hose storage area to a more convenient and easily accessible location on the combine. Additionally, the updated models offer two new ports close to the front of the machine for improved access to compressed air near the cab and header areas.

Stone trap sensor

Enhancing operator awareness, the new CR combine models feature a stone trap door position sensor. This sensor detects and alerts the operator in case the stone door is left open to prevent the possibility of grain loss.

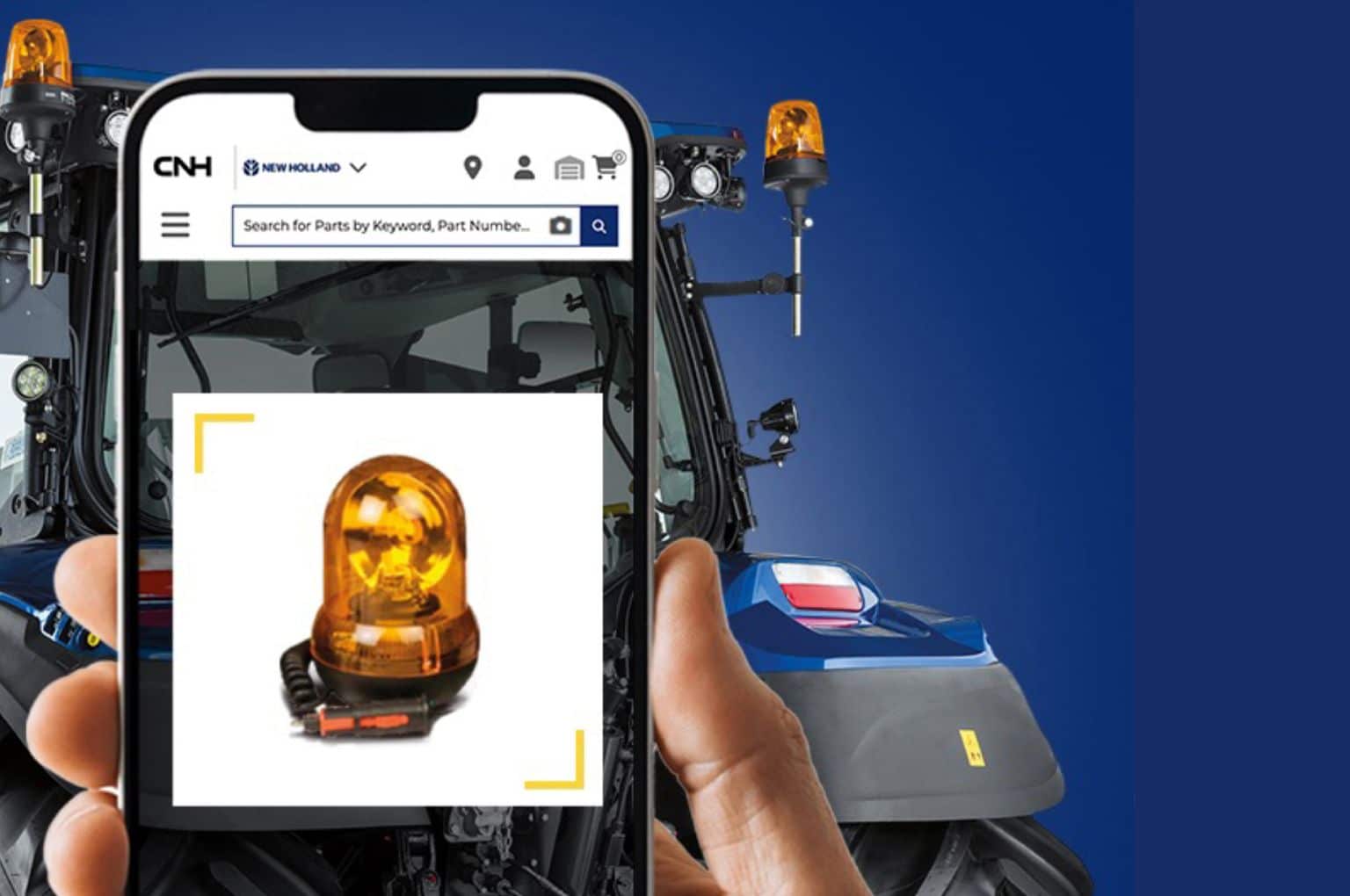

New crop additions to IntelliSense

New Holland’s IntelliSense harvest automation continues to evolve with the addition of two new crop types: Milo and oats. These two new crop types build upon existing IntelliSense crop capability in wheat, barley, corn, soybeans, canola and rice.

IntelliCruise II feature

The auto feed rate control system, IntelliCruise II, will become a standard feature on all CR combine models. By refining the IntelliCruise algorithm, the crop load indication is based on engine load only, meaning the Feedrate sensor in the feeder drive line is no longer required.

Factory fit NutriSense

The NutriSense NIR crop analysis system will now be available from the factory on all Model Year 2024 combines. This optional system features on-the-fly crop composition analysis and mapping, which is fully integrated in the IntelliView display. The option is available with 3- or 5-year subscriptions that provide location-specific calibration curve updates for three crops and seven nutrients from the factory with the ability to upgrade and include additional crops. Nutrient composition data collected by this system can be used to make storage and marketing decisions about the year’s harvested crop, as well as support decisions for the next year’s crop input planning.

Second display option

A second display will be added to all models when configured with both IntelliSteer and IntelliSense systems.

Greater standardization across all CR models

Dynamic Feed Roll technology provides efficient on-the-go stone collection and ensures excellent crop flow in even the toughest conditions. The system becomes standard on the CR7.80 and CR7.90 combines. This addition will be complemented by the new stone trap sensor.

Another important upgrade for the CR7.80 and CR7.90 models is the release of the Dynamic Flow Control rotor vane system, now available on models with 17″ rotors. Similar to the advantages provided on the larger models, the Dynamic Flow Control in-cab adjustable vanes for the CR7.80 and CR7.90 give the operator the ability to control crop flow through the rotors and find the optimal balance between threshing performance and power efficiency from the comfort of the cab. Also, like the larger models, the Dynamic Flow Control rotor vanes can be controlled by the IntelliSense automation system and monitored via the IntelliView display.

All CR7.80 and CR7.90 machines will now be “IntelliSense-ready” with the remote preserve feature and Grain Cam-ready grain elevators as standard equipment, such that these machines can be upgraded to full IntelliSense even if that option is not ordered from the factory. In addition, all CR9.90 and CR10.90 models will be equipped with IntelliSense as standard equipment.

Check out the New CR at the upcoming Farm Progress Show in Decatur, IL, USA.