With the XERION 12 Series, Claas presents new tractors in the highest performance class. The two models come in above the XERION 4200 – 5000 and feature the efficient low-engine speed drive concept 2.0, maximum power outputs of up to 653 hp, the CEMOS operator assistance system, hydraulic pump capacity of up to 537 l/min and a new spacious four-point suspension cab. In addition, the TERRA TRAC models are equipped with newly developed, damped crawler tracks. Strength is more than power.

The XERION has been on the market already for more than 25 years. The two new more powerful 12.590 and 12.650 models are designed as specialists for the toughest of draught work, such as pulling wide cultivators and seed drills, as well as chaser bins. In addition to North America, central Western Europe and South America, the core target markets include countries such as Australia.

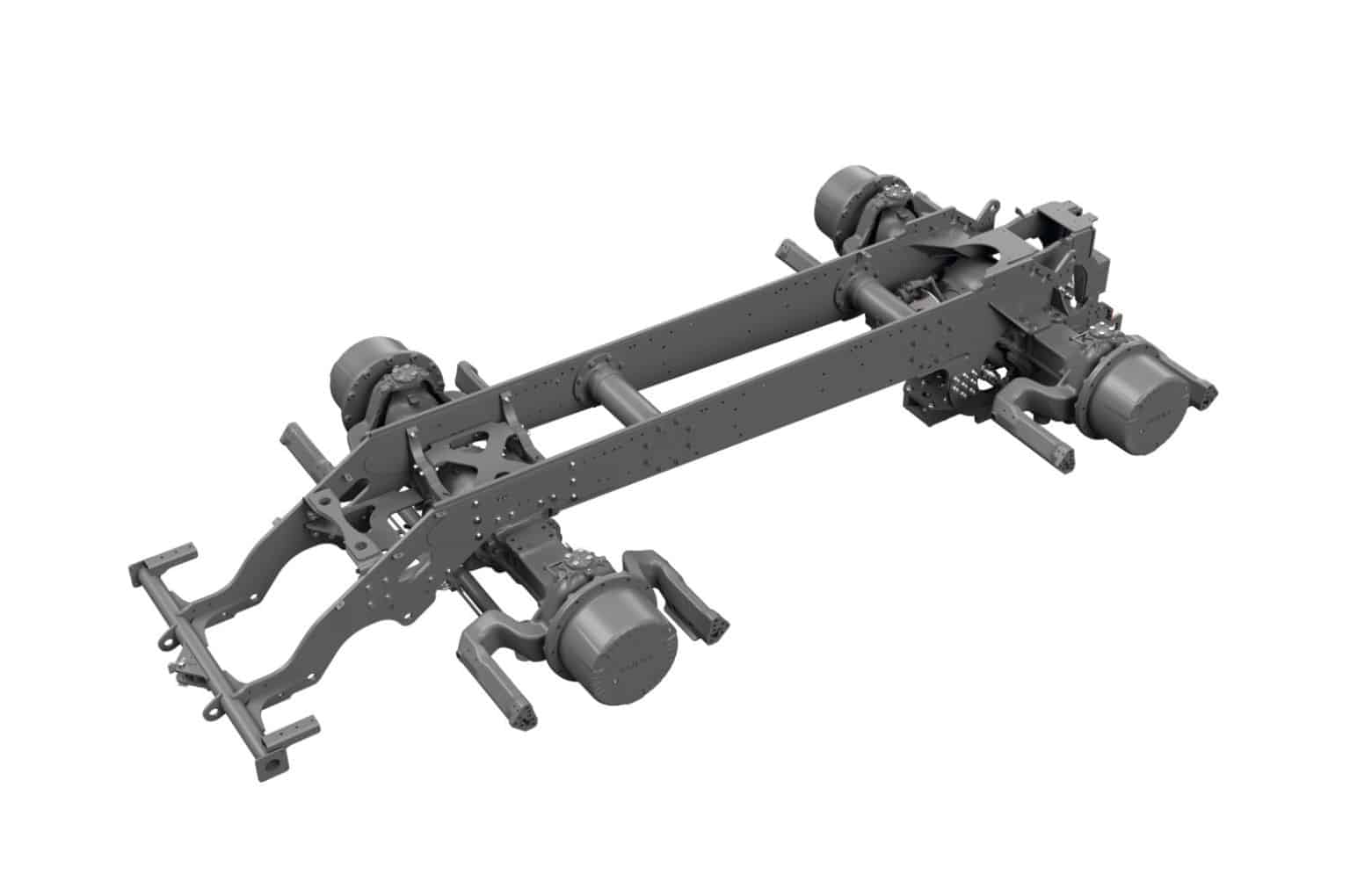

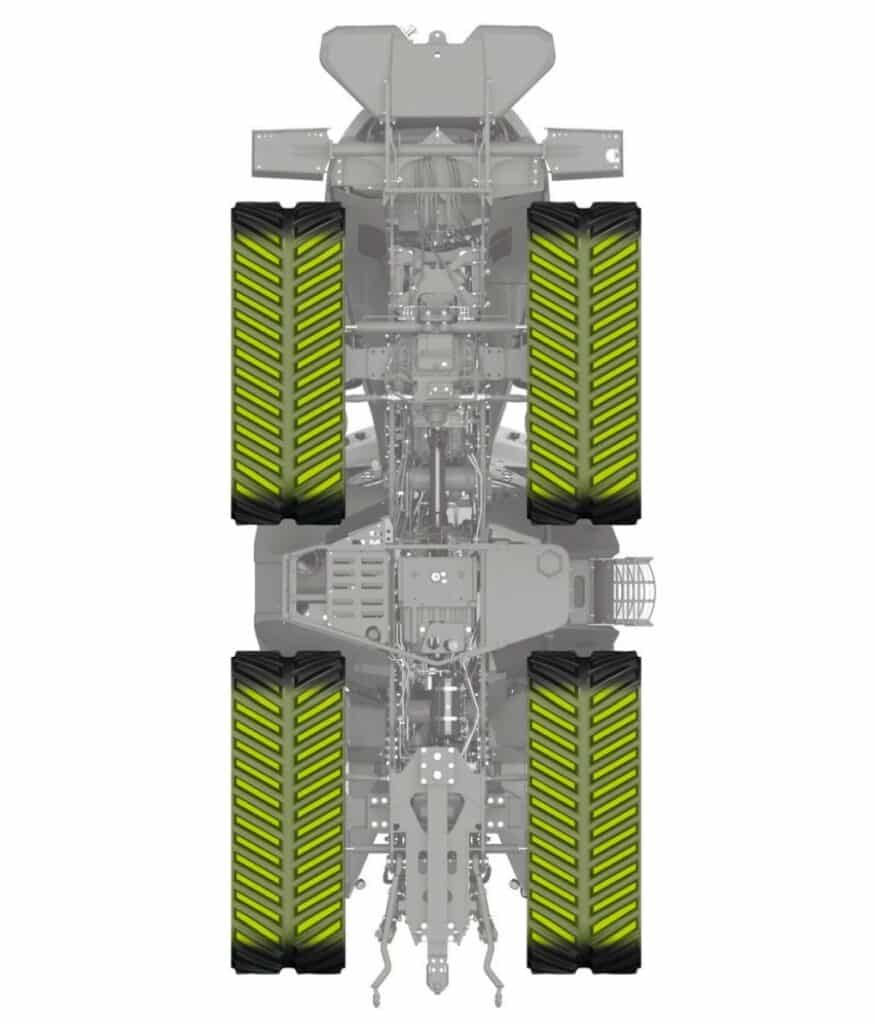

The basic concept with a bolted, resilient central frame and two steering axles was adopted from the XERION 4200, 4500 and 5000 models and adapted to reflect the increased output, higher weight and larger track width. New TERRA TRAC triangular crawler track units or dual tyres up to 800/70 R42 transfer the power gently and efficiently to the ground, while the driver enjoys an all-round view in the large, four-point-suspended cab. The low-speed concept 2.0 marks a synthesis between the efficient, high-cubic-capacity Mercedes-Benz engine and high-performance, low-engine speed hydraulics featuring high hydraulic output. The XERION 12 Series with CVT transmission and CEMOS operator assistance, delivers a maximum power output up to 653 hp and up to 3100 Nm of torque.

The new XERION 12 Series with up to 653 hp, 3100 Nm, new TERRA TRAC crawler tracks, four-point-suspended cab with

all-round view and hydraulic output of up to 537 l/min

The Mercedes Benz 15.6 l OM473 LA six-cylinder in-line engine is familiar from the JAGUAR and LEXION and combines enormous torque with fuel efficiency and low maintenance costs. In the XERION 12.590 this power unit delivers 585 hp from 1600 rpm and up to 653 hp in the XERION 12.650. Turbo compound technology with wastegate turbocharger ensures enormous power development, even at low engine speeds, and maximum efficiency under full and partial load at the same time. As a result, the maximum torque – an impressive 3100 Nm in the XERION 12.650 – is available even at 1300 rpm. The idling speed is set at a low 650 rpm.

The coolers for engine, transmission, hydraulics and axles are sized for maximum efficiency and positioned for easy access. The cooling area can be cleaned at the press of a button with the aid of the hydraulic reversible fan. The fuel tank in the XERION 12 Series has a capacity of 1400 l, while the AdBlue tanks can hold 90 l. The central position of the fuel tank means that the tractor’s weight distribution does not change during the working day as the fill level falls. The engines have an oil change interval of 1000 operating hours and a maintenance-free Stage V exhaust gas after treatment system.

CVT now available up to 650 hp

The XERION 12 Series is equipped with the latest generation CMATIC continuously variable transmission, matched to the engine’s optimal torque and consumption characteristics. The starting and deceleration torque of the continuously variable, split-power drives protect cultivators and seed drills by avoiding peak loads on the frame structures and hitching devices caused by abrupt shifting or engaging and disengaging with the implement in working position. Nevertheless, the XERION still delivers the full engine torque from the minimum speed of 0.05 km/h.

Thanks to four automatically selected drive modes, the transmission works with a high degree of efficiency, transferring power to both axles continuously. In combination with the multi-pass effect and the 50:50 weight distribution under traction, power is transferred to the ground without compromise while at the same time ensuring maximum soil protection – regardless of the steering angle. This means that full traction is available even when working on hilly ground or negotiating obstacles.

The XERION 12 TERRA TRAC reaches a top speed of 40 km/h at an efficient 1400 rpm. The TRAC wheeled version has a top speed of 50 km/h.

CEMOS on board

The self-learning, dialogue-based operator assistance and process optimisation system CEMOS is now available for the XERION too. Double-digit percentage improvements in fuel consumption and area output can be achieved by optimising power transmission, drive management and ballasting (DLG Test Report 7096). Furthermore, CEMOS incorporates a plough settings assistant as well as the Terranimo app. Once the operating conditions have been entered, the app calculates and displays the compaction risk in three soil layers to help the driver optimise the machine settings in favour of greater soil protection.

Low-engine speed hydraulics

Up to three load-sensing pumps supply external consumers with a maximum 537 l/min at 1900 rpm. This output means that even the widest air seeders with a continuously high oil demand can be operated even more efficiently at greatly reduced engine speed. Up to eight double-acting control circuits continuously supply sufficient oil to cultivation implements, drills and precision air seeders too, with prioritized control circuits able to deliver up to 140 l/min to the highest consumers.

The flow rate of each spool valve is shown in the CEBIS terminal in the form of a graphic display. When working with attached implements that have multiple consumers with a high demand for oil, this enables the operator to adjust and prioritize flow rates accordingly.

TERRA TRAC 400 and dual tyres up to 800/70 R42

New crawler track assemblies with positive drive for the XERION 12 Series satisfy customer requirements in terms of power transmission, soil protection and comfort. Sturdy steering axles with two auxiliary steering cylinders per axle and large drive wheels transfer power gently to the drive belts while simultaneously engaging eight lugs. The two-part frame construction of the crawler tracks enables the two pairs of mid-rollers which are mounted on bogies to adapt to ground contours independently of the main frame. Large rubber blocks between the undercarriage and the main frame of the crawler track assembly effectively buffer bumps and vibrations.

When equipped with dual tyres up to 800/70 R42, the TRAC version achieves an unrivalled footprint in wheeled tractors. In addition to the multi-pass effect, ideal 50:50 weight distribution regardless of tank level and combined with the efficient drivetrain with low-engine speed concept 2.0, this reduces fuel consumption by 8 to 10 per cent per hour. Thanks to the large triangular crawler tracks assemblies, the TERRA TRAC version achieves the same level of efficiency with 30 or 36 inch-wide (762 or 914 mm) track belts.

With two steering axles, the TERRA TRAC and TRAC steer tightly and precisely with the cab and rear linkage remaining in mid-axle. The steering behaviour is similar to that of standard tractors: steering manoeuvres and turning operations are implement- and driver-friendly with minimal track formation. In addition to the standard steering programme with trailed rear-wheel steering, classic four-wheel steering with simultaneous steering of the front and rear axle is also available, and the TRAC can also be driven in gentle mode (reduced crab steering) for silage clamp work. The DYNAMIC STEERING function available in the standard steering programme halves the number of turns of the steering wheel needed during fieldwork and further reduces the steering torque.

The large ground contact area ensures gentle and efficient transfer of tractive power. In combination with the efficient drivetrain this reduces fuel consumption by 8 to 10 percent. The full frame with two steering axles enables precise and comfortable steering movement.

Four-point suspension cab

The cab has been extended by 27 cm at the front, making it currently the largest command centre in the premium tractor segment. Footrests can be factory-fitted behind the steering column and on the right-hand A-pillar. The driver’s seat is available in three versions with standard upholstery or optional high-quality cotton or leather upholstery, and can be rotated by 40° to give the driver a perfect view of attached implements. Both the exhaust gas aftertreatment system and the exhaust system are fully integrated into the right-hand side of the chassis under the cab. Combined with the slender steering column, this ensures all-round visibility. Key functions are operated and monitored via the ergonomic armrest with CMOTION multifunction control lever and the CEBIS touchscreen terminal. This means that a standardised control concept is now available for all Claas tractors between 125 and 653 hp from the ARION 500 upwards.

The new four-point cab suspension provides a high level of comfort. By cushioning impacts and countering rolling movements, it enables drivers to concentrate fully on the job in hand without tiring even during long working days. In addition, the cab has been further decoupled from the chassis to significantly reduce the impact of noise and vibrations from the drivetrain and chassis on the driver.

The new XERION 12 Series offers a large cab with four-point suspension. The driver’s seat rotates by 40° to the right.

GPS PILOT CEMIS 1200

The XERION 12 Series comes with a customisable package for ISOBUS and precision farming applications. Buyers can choose from automatic steering by GPS PILOT with different correction signals, both on- and off-line Task Management, and precision farming applications with Section Control and Variable Rates Application (VRA). All functions for modern, precise and site-specific work are available in conjunction with the 12-inch CEMIS 1200 terminal which uses the familiar CEBIS control concept. With CLAAS connect, new licenses or activations can be transferred straight to the terminal online, as can tasks with predefined tracks and application maps from connected farm management information systems (CLAAS API).

The ability to automatically create multiple reference lines per field provides a further efficiency boost. Using recorded or imported field boundaries, A-B lines and contours for different areas and sections of the field can be calculated and saved before cultivating the field. This feature simplifies work in irregularly shaped fields, as several headland sequences and rounded field boundaries can be saved as references in addition to the main working direction.

The tramline management feature in CEMIS 1200 also reduces the workload. Tramlines are marked in colour on the screen and a signal alerts the driver when to create one the same. This means tramlines can no longer be missed, leaving the driver to focus fully on the optimum performance of the tractor and attached implement.