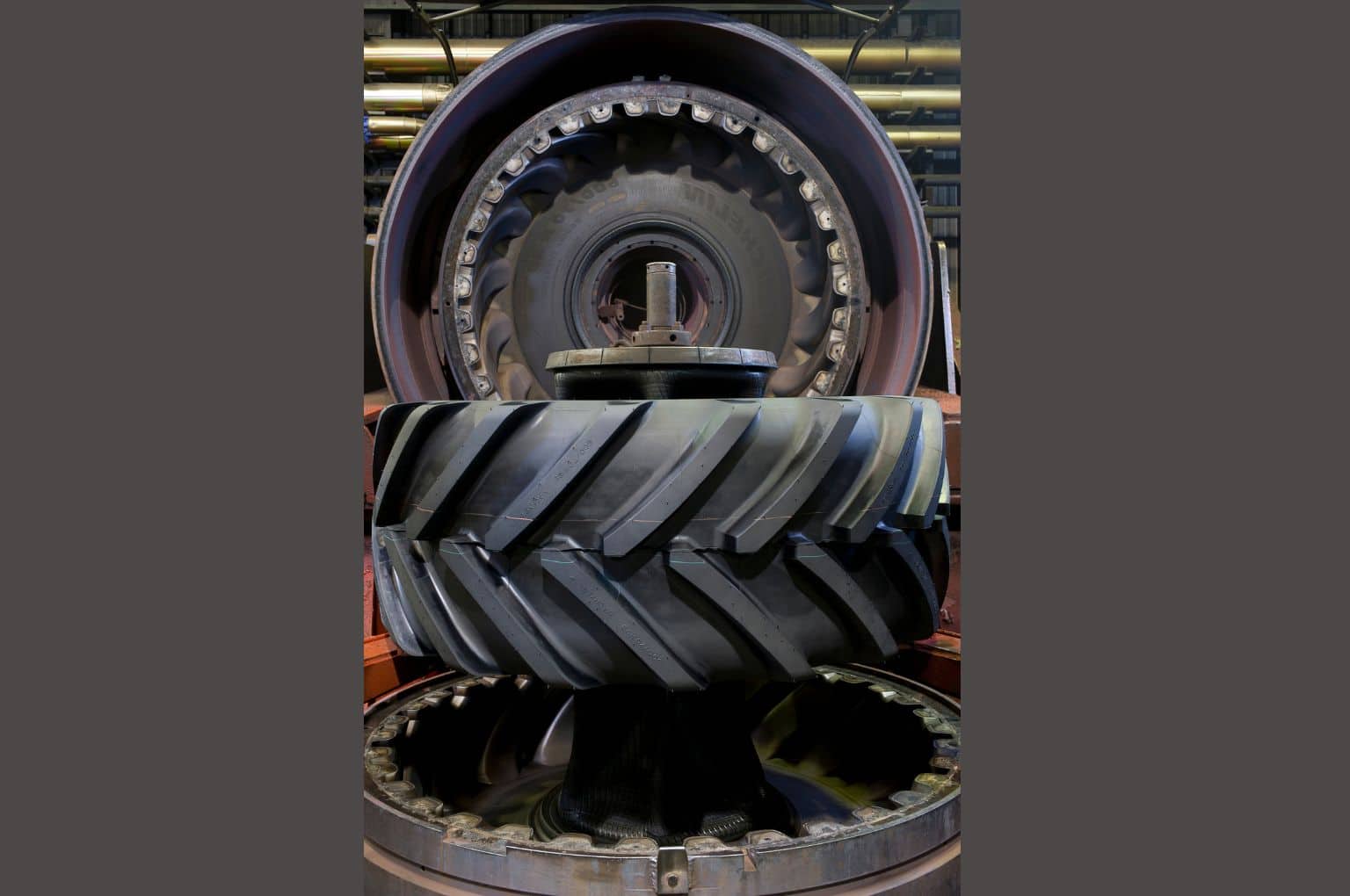

Michelin is celebrating the 60th anniversary of its industrial ag tire site in Troyes, France. The site exports 85% of its production (66% to Europe and 29% to North America). Clients include major manufacturers such as CNH Industrial, AGCO, John Deere and Claas.

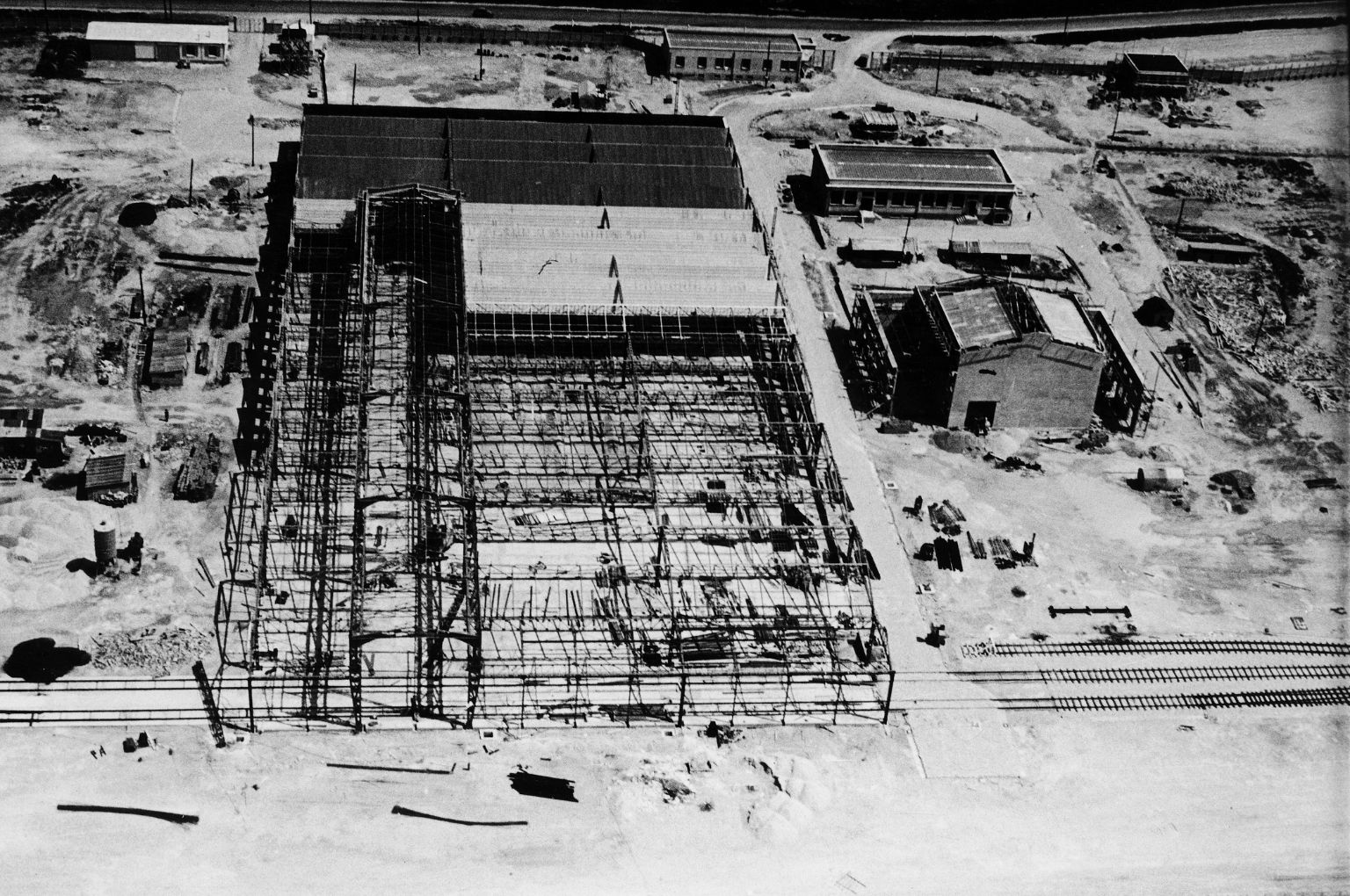

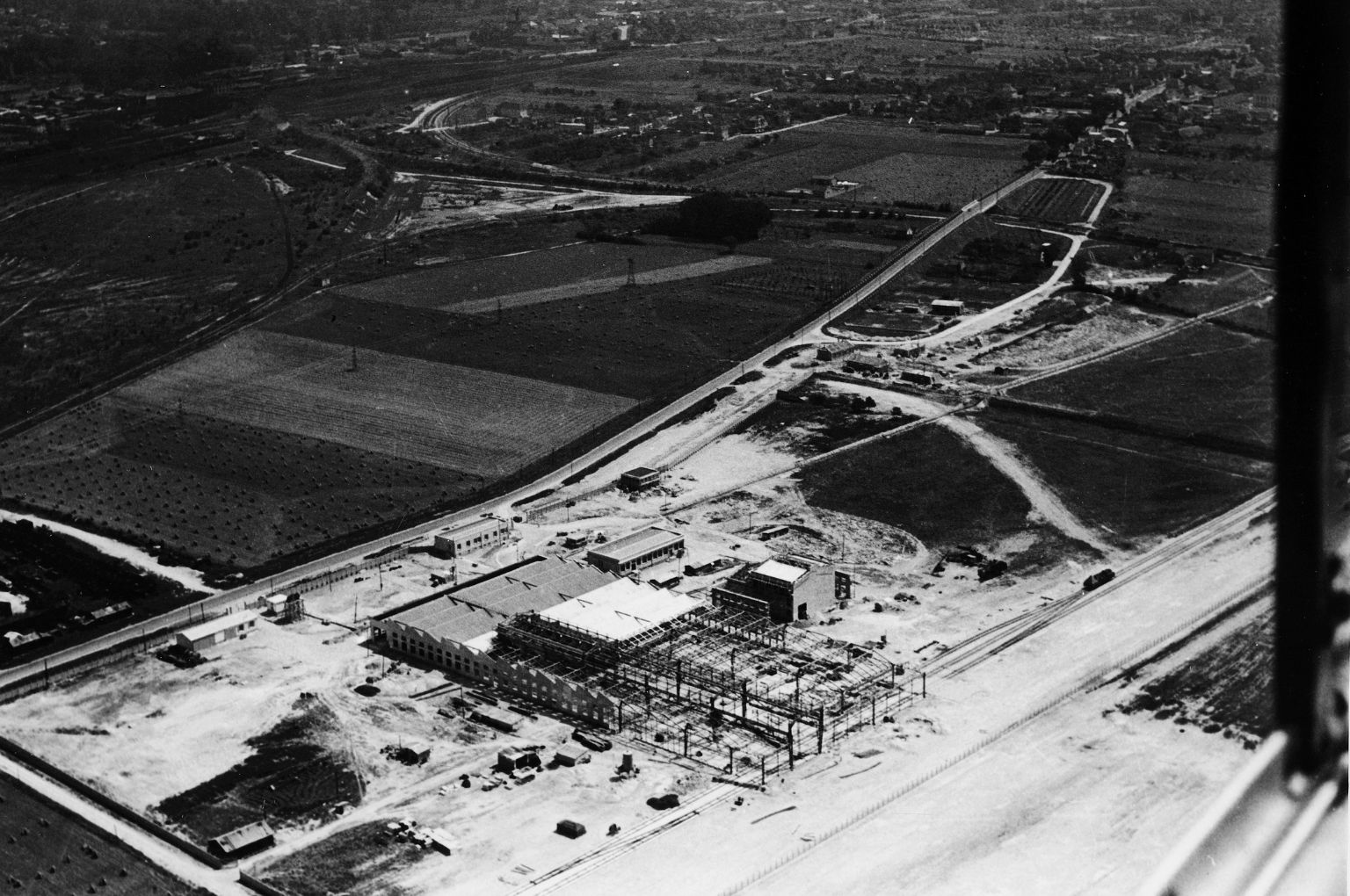

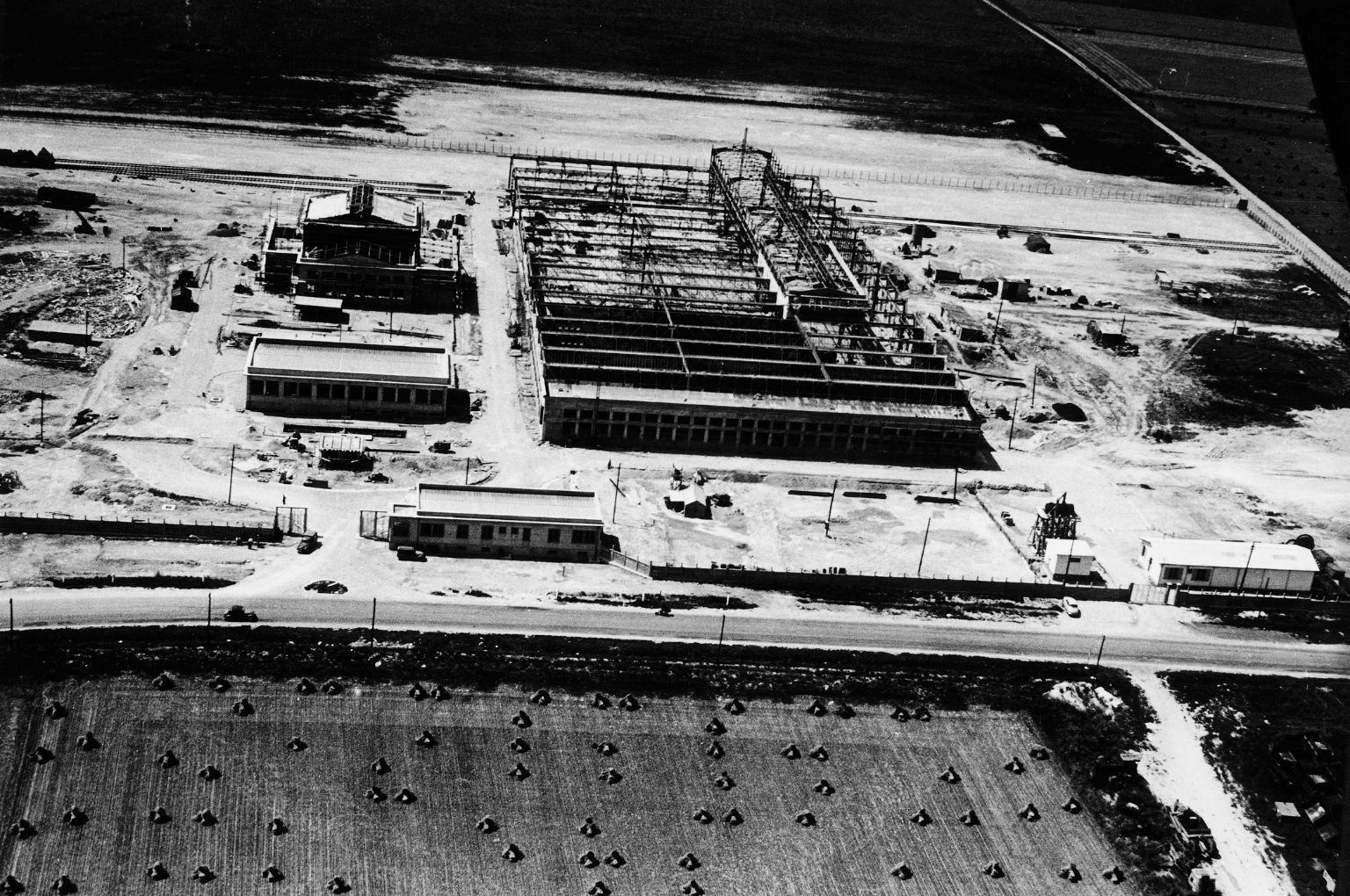

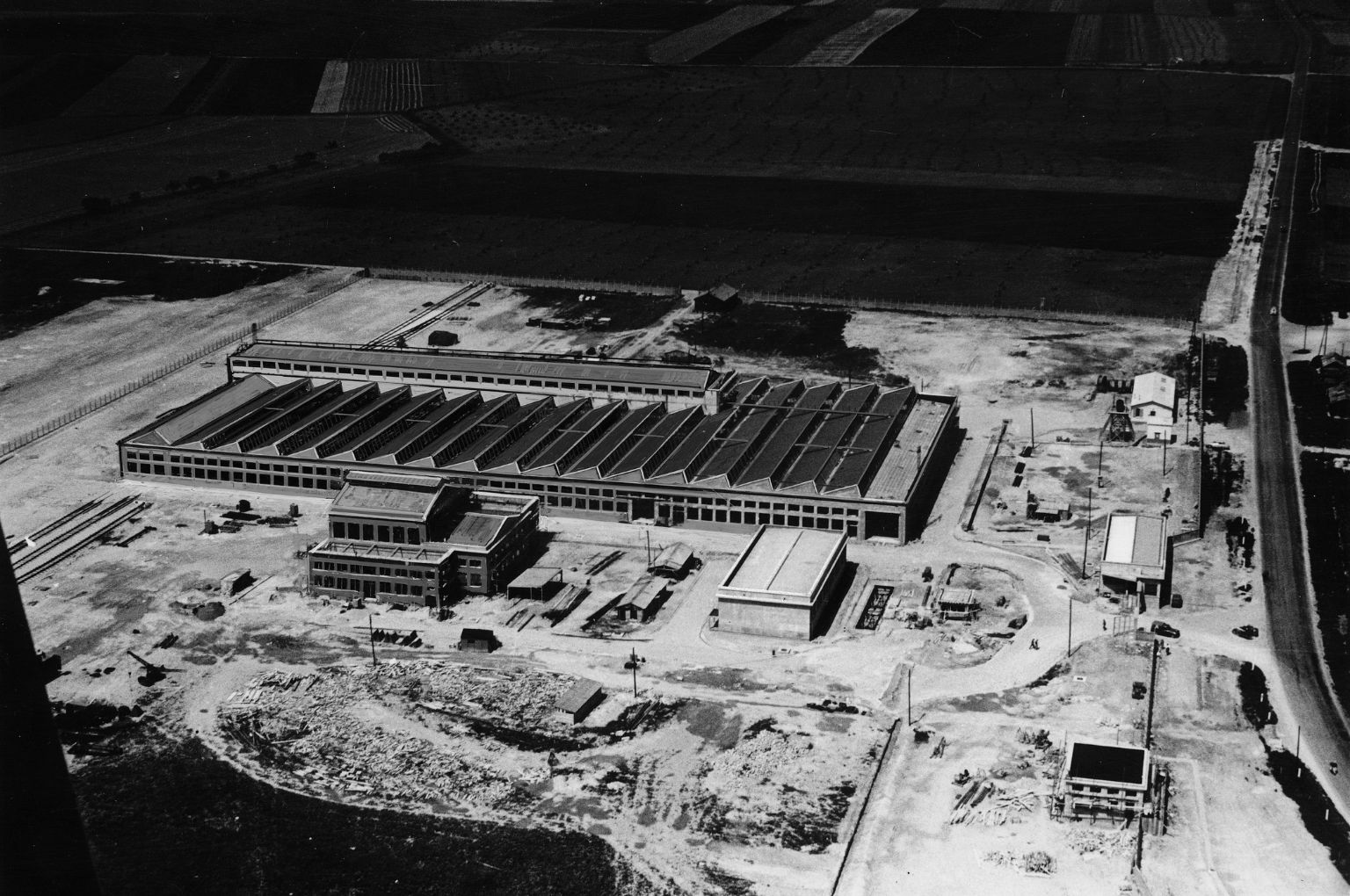

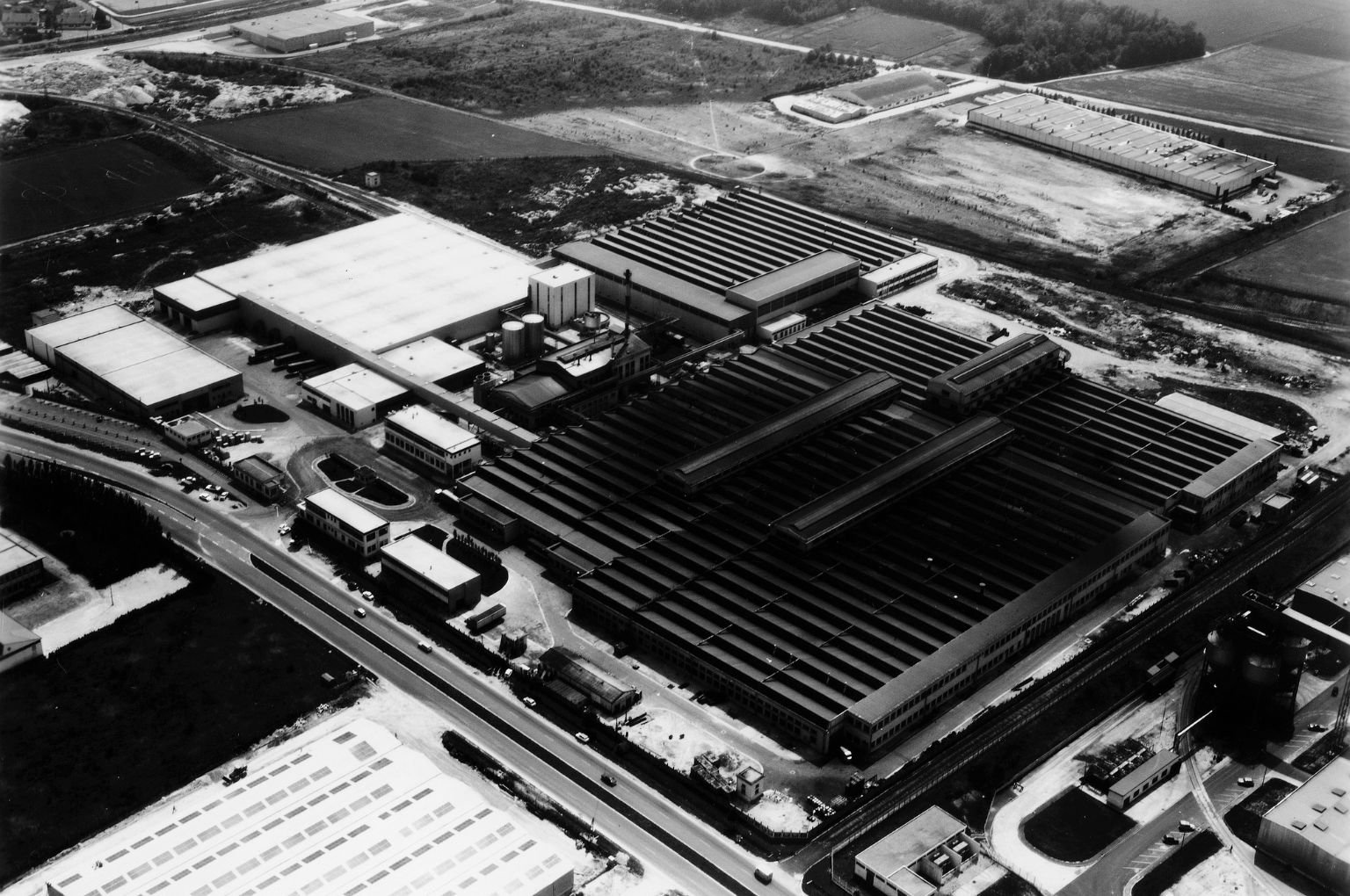

At the start of the 1960s, Kleber, whose main plant is located in Colombes in the Paris region, wished to expand and decided to open a site in Troyes due, in particular, to the proximity with its headquarters and its long-standing industrial experience and skills. In January 1963, France’s second Kleber site opened under the code name of UP2 and produced its first car and agricultural tires. The factory expanded quickly. Faced with significant financial difficulties, Kleber was taken over by the Michelin Group in 1981. Becoming part of the Michelin Group gave it a new lease of life. In 1986, the site became the first Kleber plant to produce Michelin brand tire. In 1996, the plant, which produced tires in 248 different sizes, actively participated in creating a range of agricultural products for the Group and developing Michelin’s new agriculture strategy.

In the year 2000 Michelin entered into a major restructuring plan to reduce the group’s industrial footprint in Europe and to specialize its plants. This plan validated the closure of the Troyes car tire production department. In 2012, the Kleber factory became a Michelin brand factory in order to take advantage of all the Group’s industrial technology and to maintain its positioning on premium markets.

5 years to co-build the future

In November 2021, the Michelin Group announced a project for 2021-2026 to enable the factory to strengthen its positioning on the premium agricultural tire market. The project provided for a far-reaching modernization program for the tire production activity and the transfer of rubber mixing. It was buoyed by a substantial investment plan of up to 80 million euros over 5 years, for modernizing the agricultural tire production department and enhancing quality of life at work.

The site’s 2021-2026 roadmap should reinforce its overall performance and consolidate its position in the Group’s industrial strategy in Europe, focusing on two priorities:

– Producing tomorrow’s tire ranges at competitive prices by moving into more lucrative markets, in particular high-power tractor markets

– Developing the site’s attractivity by enhancing quality of life at work in all its aspects.

Modernizing the production department

In 2022, the site introduced its first robots and automated forklift trucks will also be implemented in 2024. The Troyes plant is currently working on an innovative, more effective and ergonomic agricultural tire assembly machine. Co-developed by a multidisciplinary team of ergonomists, engineers, product developers, technicians and the site’s production operators, the first prototype is set for completion in December 2023.

Environmental commitment

In 2020, the Troyes site defined its zero CO₂ roadmap to meet the Michelin Group’s objective to half emissions by 2030 and to achieve carbon neutrality by 2050.

The site aims to improve its energy efficiency by 2% per year. This result is possible thanks to awareness-raising among factory staff, the insulation of machines and buildings, daily maintenance and management and digitalization, which allows the impact of actions to be evaluated rapidly.

To reach the Group’s decarbonization objectives for 2030, two additional technical levers are being developed: an overhaul of the heating system and the electrification of some industrial processes.

The Troyes plant’s environmental priorities also include achieving a significant reduction in water consumption. The various modernization projects, as well as the development of processes converted into closed circuits, will help make considerable water savings by 2024.

The transformation of the Troyes site requires particularly strong commitment on a human level from all the teams and at every level of the establishment, in order to meet a series of challenges: to support rubber mixing department staff, enhance the site’s attractivity and working conditions, develop skills, step up social dialogue, etc.

Preserving the quality of social dialogue

Since 2019, the quality of social dialogue has been crucial for pre-empting, preparing and implementing the site’s transformation under the best possible conditions. Joint troubleshooting of the plant’s challenges (production costs, ergonomics, attractivity, reactivity) has enabled the site’s new roadmap to be cobuilt, in particular the section on investments and social assistance.

In a complex period, characterized by structural reorganization and economic slowdown, maintaining high-quality social dialogue is fundamental for the project’s success.

The site enlisted the support of a specialized firm and introduced a series of measures (skills assessments, vocational guidance, ‘day in the life’ days to discover the production department, job fairs) to enable every employee concerned to make the right choice. In 2023, the progressive drop in activity enabled a first group of some thirty employees to make their decision: 15 employees opted for external mobility; 7 will take early retirement, 2 employees will join the agricultural tire production teams in Troyes; and 5 people will continue with rubber mixing in Montceau-les-Mines.

Recruiting necessary skills

In parallel, the site is seeking to avoid recruitment difficulties in the Troyes basin by developing innovative programs. For example, two years ago the factory set up the Ilot Avenir program to create, in particular, a specific production area to ensure tailored monitoring for new hires. Since 2021, 30 operators have been recruited on permanent contracts within this framework, and 90% of them are still working today. The teams are continuing their efforts to develop the most efficient vocational rehabilitation programs possible, with support from their territorial partners, the Maison de Région Grand Est, the Aube Department, Troyes Metropole and La Chapelle-Saint-Luc Town.

For Pierre-Louis Dubourdeau, Vice President of Manufacturing for the Michelin Group, “the history of the Troyes site is proof that ‘Made in France’ production is a challenge that can be met. Focusing on premium products, team excellence, modernizing the production process, improving working conditions and ensuring efficient use of resources and social dialogue, the Troyes plant has, over time, fulfilled a number of demands that determine the viability of an industrial site.

Thanks to the new project, undertaken with the Group’s support, the teams have the means to continue building the site’s future”.