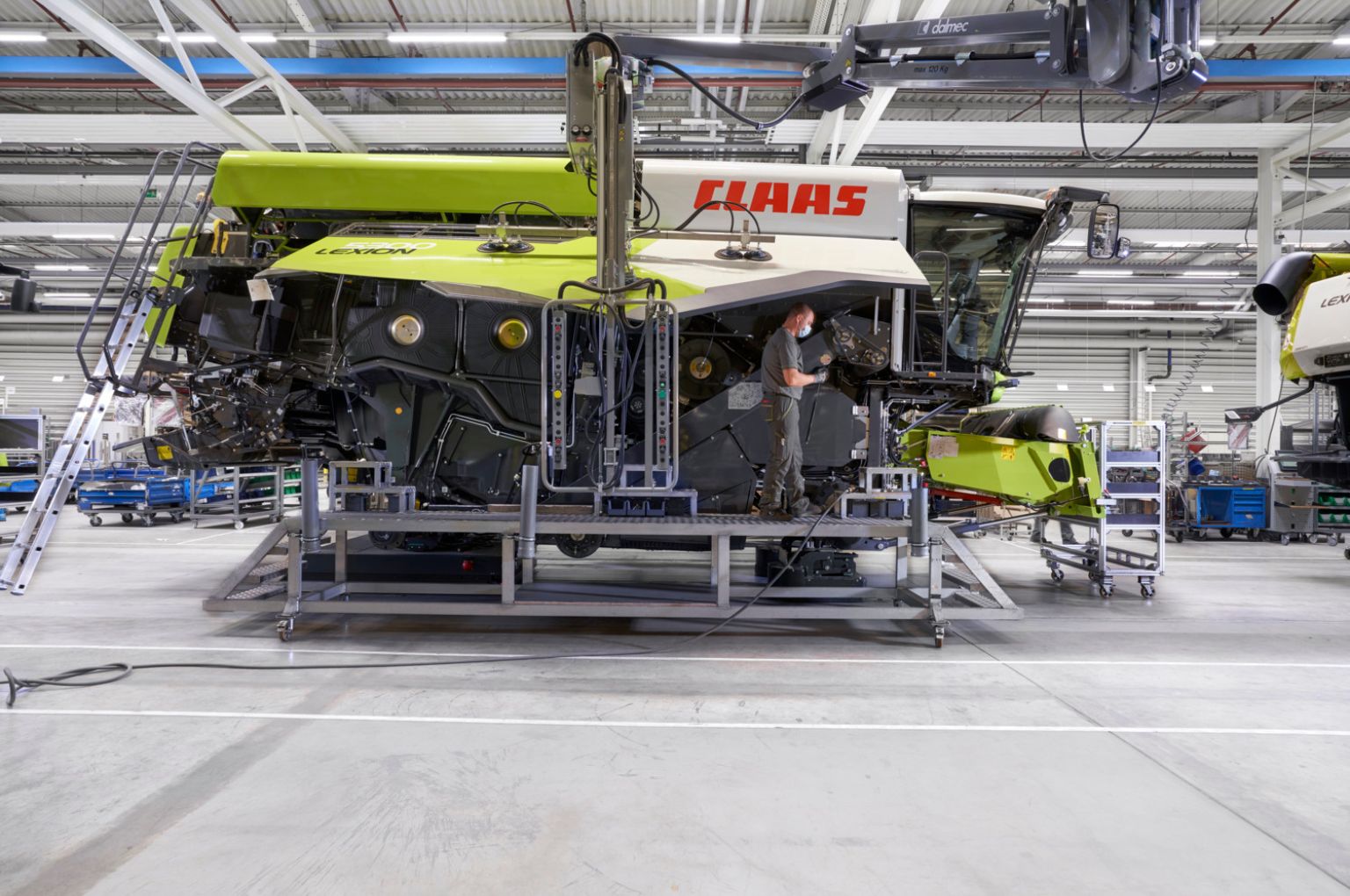

Claas has invested €44 million in ultramodern combine harvester production at its site in Harsewinkel, Germany, as part of the SynPro 2020 project. Using the latest production and logistics technologies, two model ranges can be constructed incorporating an unprecedented variety of specifications and options on just one line.

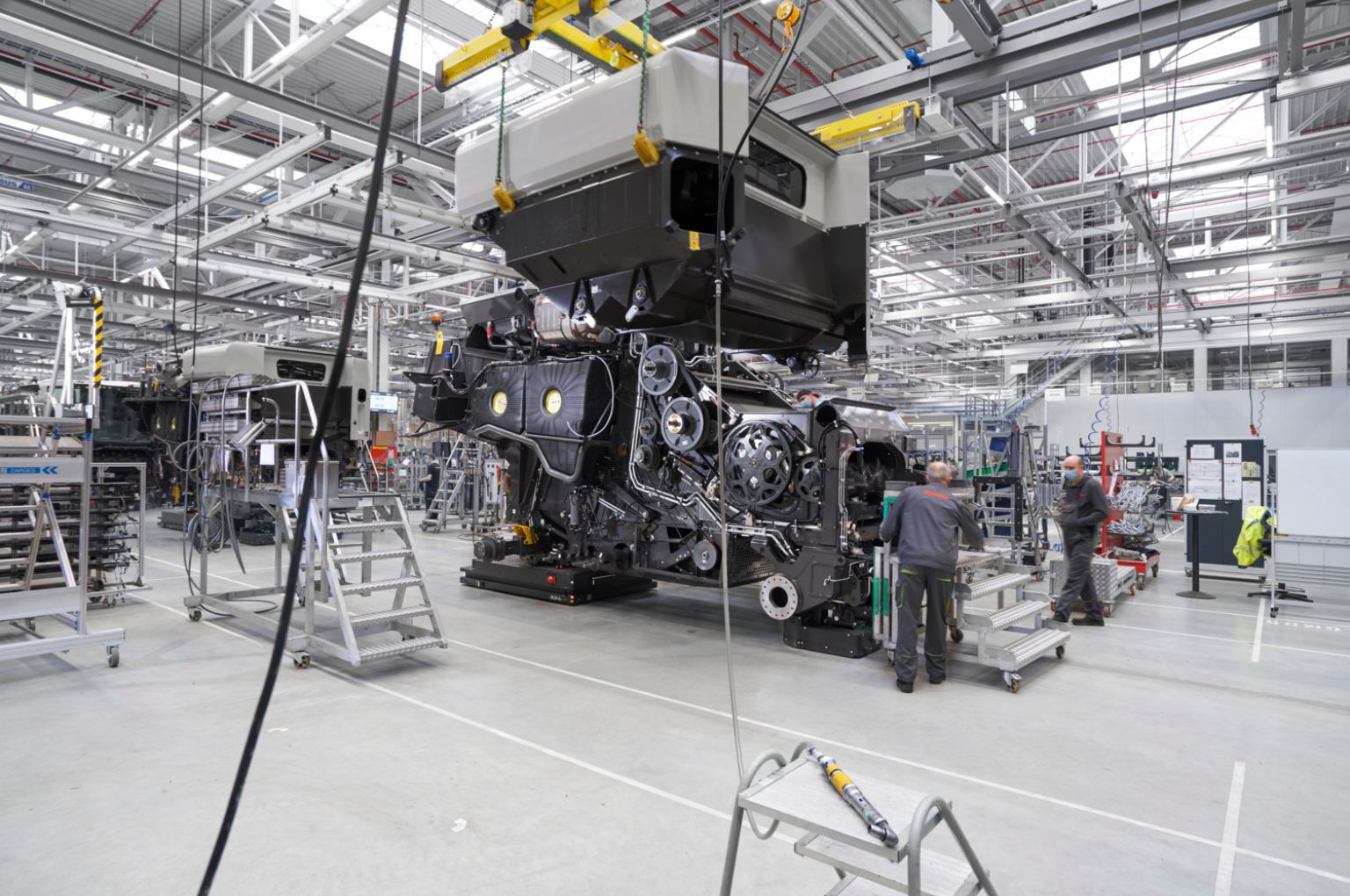

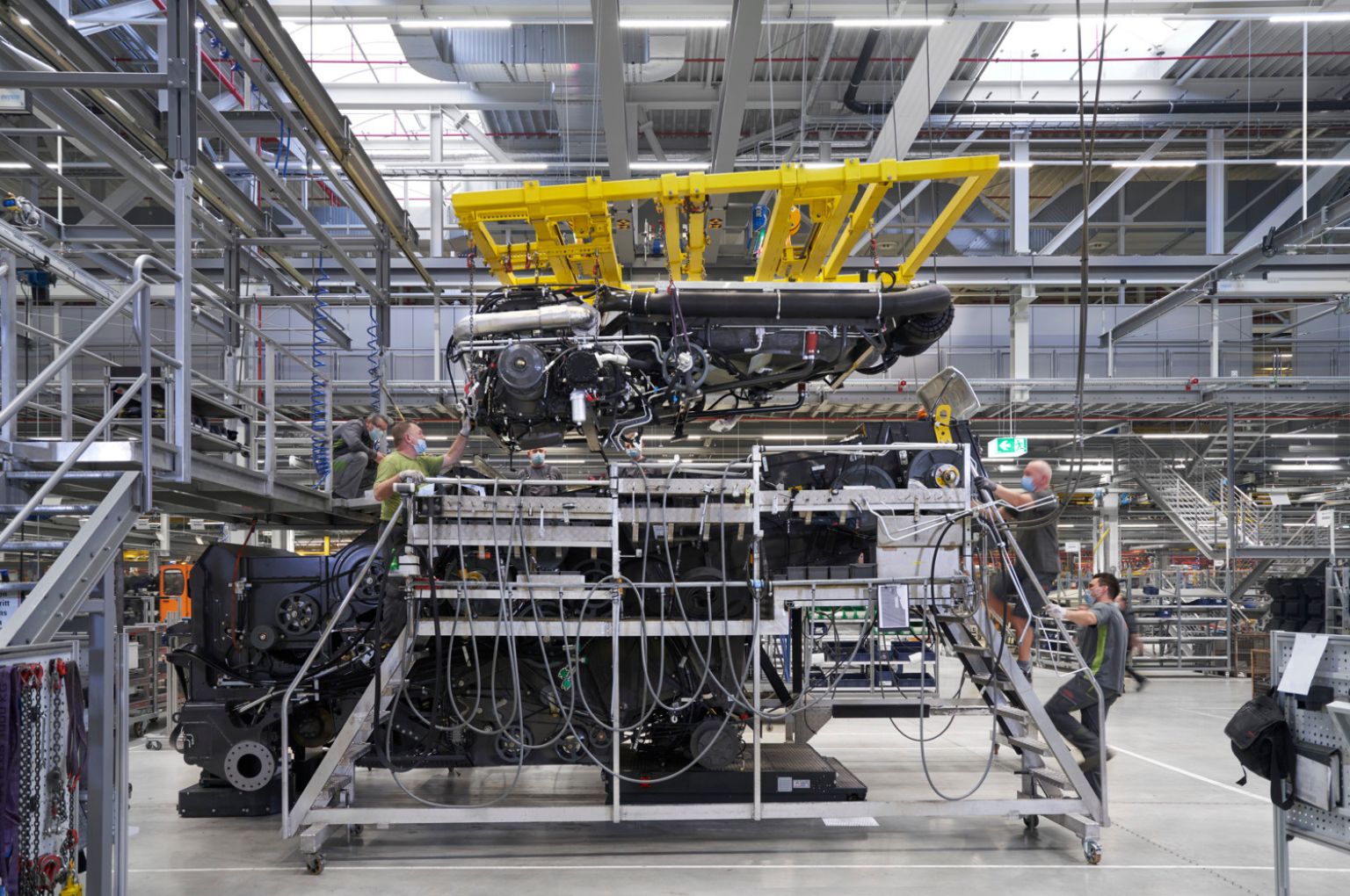

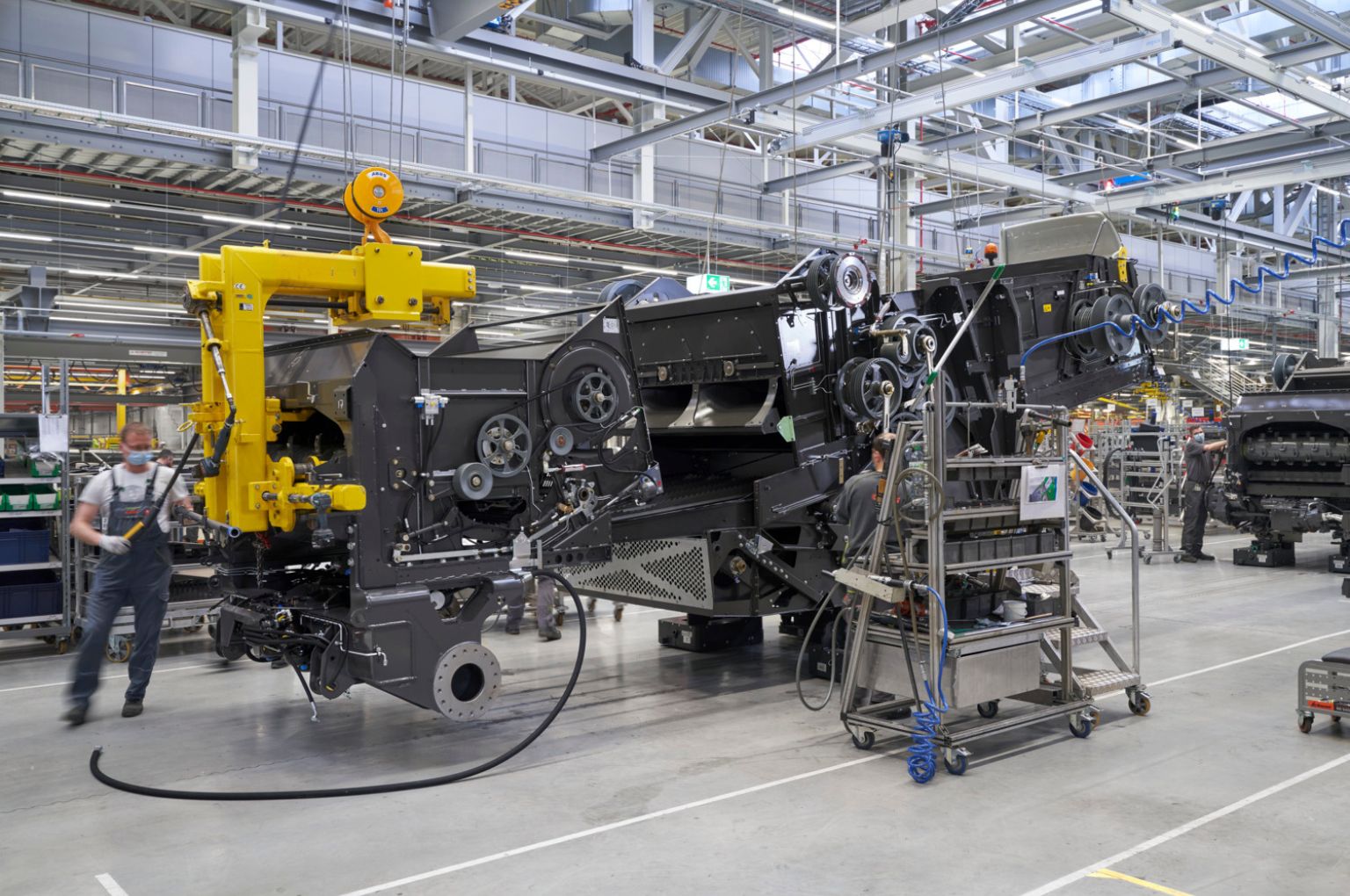

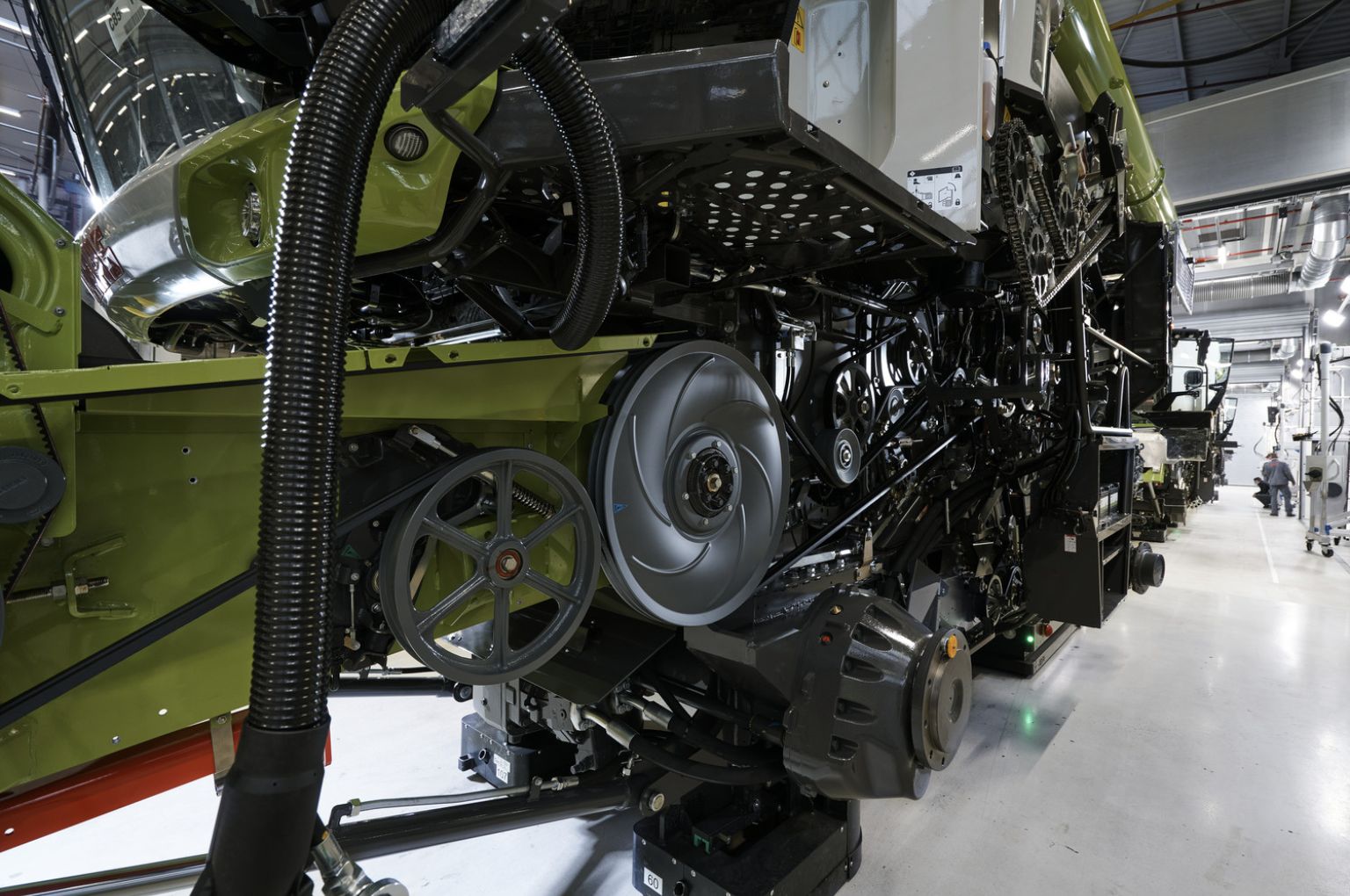

With up to 15,000 individual parts, combine harvesters are among the most complex agricultural machines ever built. Production planning, parts logistics, shell construction and assembly therefore represent a particular challenge, especially if they come with a broad variety of basic and optional features. Redesigned and rebuilt from scratch within the SynPro 2020 project, the Trion and Lexion combine harvester assembly facility at the Claas headquarters in Harsewinkel enables precisely that: unparalleled variety, highly flexible production and uncompromising quality at state-of-the-art workplaces with significant CO2 savings.

Equipped for the future

Until 2021, combine harvesters were built on two assembly lines in Harsewinkel. However, the production facility was increasingly pushed to its limits as the machines grew bigger and incorporated a wider range of technical features. To name just one example: Due to the two old assembly halls, which were built between 1952 and 1958, having ceiling heights ranging from just 4.2 to 6.0 m, it was not possible to conduct functional checks of the grain hopper on the Lexion series flagship products. Moreover, the launch of the Trion in summer 2021 called for a fresh approach: it meant that a future production facility would have to build more combines per day and cater to an increasingly wide range of models – but with greater use of identical parts. Today, the €44 million refurbishment enables the construction of over 30 combine harvester types on a single assembly line.

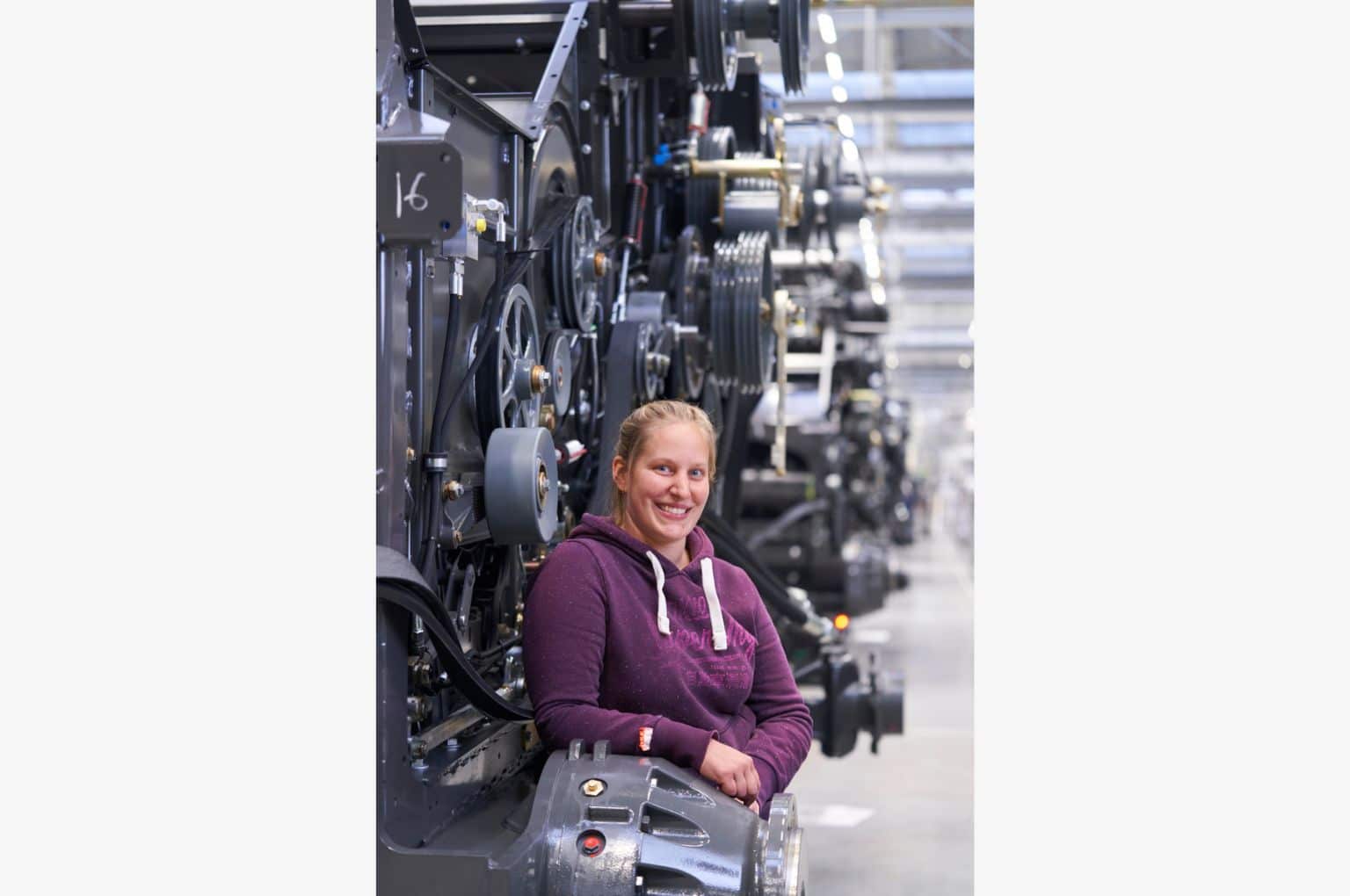

Assembled in record time, the new hall has floor space of 15,000 m2 and ceilings of up to 14 m in height. Dismantling the two old halls and erecting the new one took just 22 weeks. And that’s not all: LED lighting provides bright, almost naturally illuminated workplaces, no matter the time of day. A new 6-tonne ventilation system circulates 80,000 m3 of indoor air per hour, creating a pleasant working environment all year round. The new hall alone saves around 470 tonnes of CO2 per year thanks to efficient energy management, excellent insulation and LED lighting.

Employees can use the new common rooms, and the office workplaces used for production planning and logistics were refurbished as well. The combine harvesters now move silently through the entire assembly line and test benches on electrically powered automated guided vehicles, or AGVs for short. When combined, these factors create a motivational working environment that promotes maximum concentration at the workplace – another vital ingredient in the accustomed Claas quality. The measures have already resulted in CO2 savings of 470 tonnes per year.

Planned and documented to the last bolt

Product diversity and increased output, up to 28 combines per day in single-shift operation, also demand adjustments in shop floor management and intralogistics. Parts and modules for each combine harvester are delivered just in time to the main assembly line from sub-assembly lines that feed in from each side. Smaller supplier parts are stored in the ‘supermarket’, while larger components such as engines and axles are prepared for assembly and mounted shortly after delivery. Directly adjacent to the new assembly hall, shell construction cycles for components such as the threshing unit, residual separation, grain tank or grain tank unloading tube and downstream painting run like clockwork to ensure a perfect fit. This takes experience, coupled with state-of-the-art IT systems and the seamless tracking of all production steps in real time.

Everyone in Harsewinkel – and at all other Claas production sites – works towards a common goal: uncompromising production quality and a maximised share of ‘right first time’ to deliver flawless machines to the first round of quality control. Nonetheless, the six ultra-modern test benches that were put into operation in 2020 still have the final say. Not only are they used to perform the first comprehensive quality controls, but also the important initial commissioning of the machines. They run through all the mechanical, hydraulic and electrical functions to check for flawless working order – and even test electronic features such as Cemos, Cebis and Cemis 1200 with GPS Pilot and Telematics.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)