Durable technology and a high throughput, characterise the new large square balers from Fendt. The range has been comprehensively revised for the 2023 model year. The new generation includes a new tandem axle, an updated pick-up and other smart features.

Fendt offers 13 different ISOBUS-compatible models in the standard large square baler range. These differ by various chamber dimensions, packer or ProCut cutter configuration and the type of axle. With the technical innovations, new model designations will be introduced. For example, the Fendt 1290 TC designates a square baler with a 120 x 90 cm bale chamber in tandem axle (T) configuration with the ProCut cutter (C), while the Fendt 12130 SP designates a square baler with a 120 x 130 cm bale chamber in single axle (S) and packer (P) configuration.

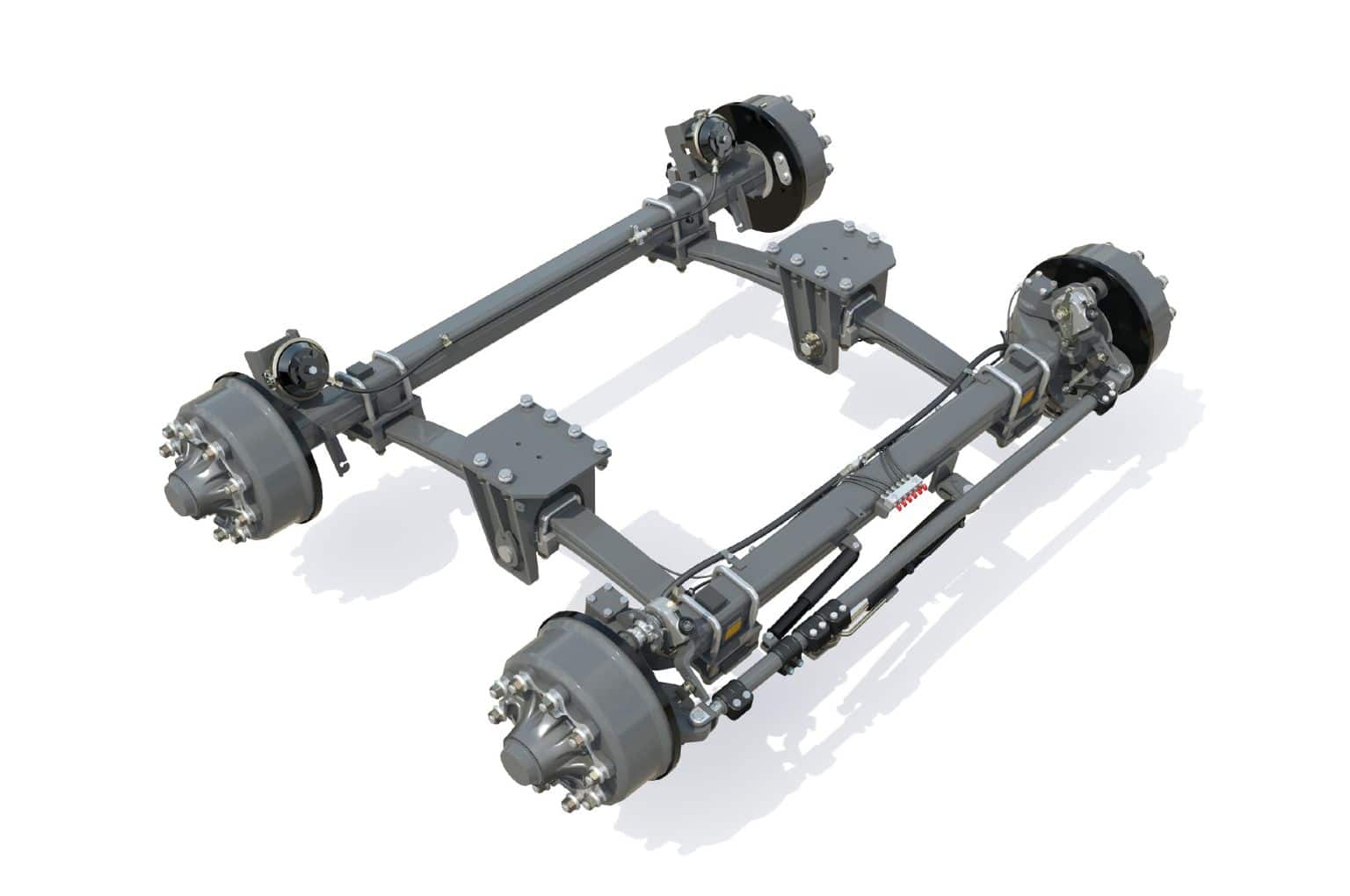

New tandem axle with suspension

All square balers with tandem axle for the 2023 model year will be equipped with a new improved suspension system and passive steering axle as standard. The design increases manoeuvrability and avoids damage to the ground and turf. In addition, all models will be equipped with larger tyres as standard compared to the previous generation. With the 620/50R-22.5 tyre dimension, the outer width of the balers remains under 3 m. The lubrication strip enables lubrication of the baler to be carried out quickly and easily and reduces maintenance times.

More powerful Pick Up

An additional row of tines increases the performance of the Pick Up. From model year 2023, five rows of tines pick up the crop even better and help to increase the working speed of the baler. In addition, new plastic pick up bands are now standard in the Pick Up. The smooth surface improves the quality of the bales and prevents the entry of contaminants into the baler. In addition, the smooth surface of the plastic pick up bands reduces friction. This ensures a clean crop flow. The resistant polypropylene of the pick up bands significantly increases their service life and reduces noise at the same time. The low weight of the pick up bands and the intelligent positioning further simplify maintenance.

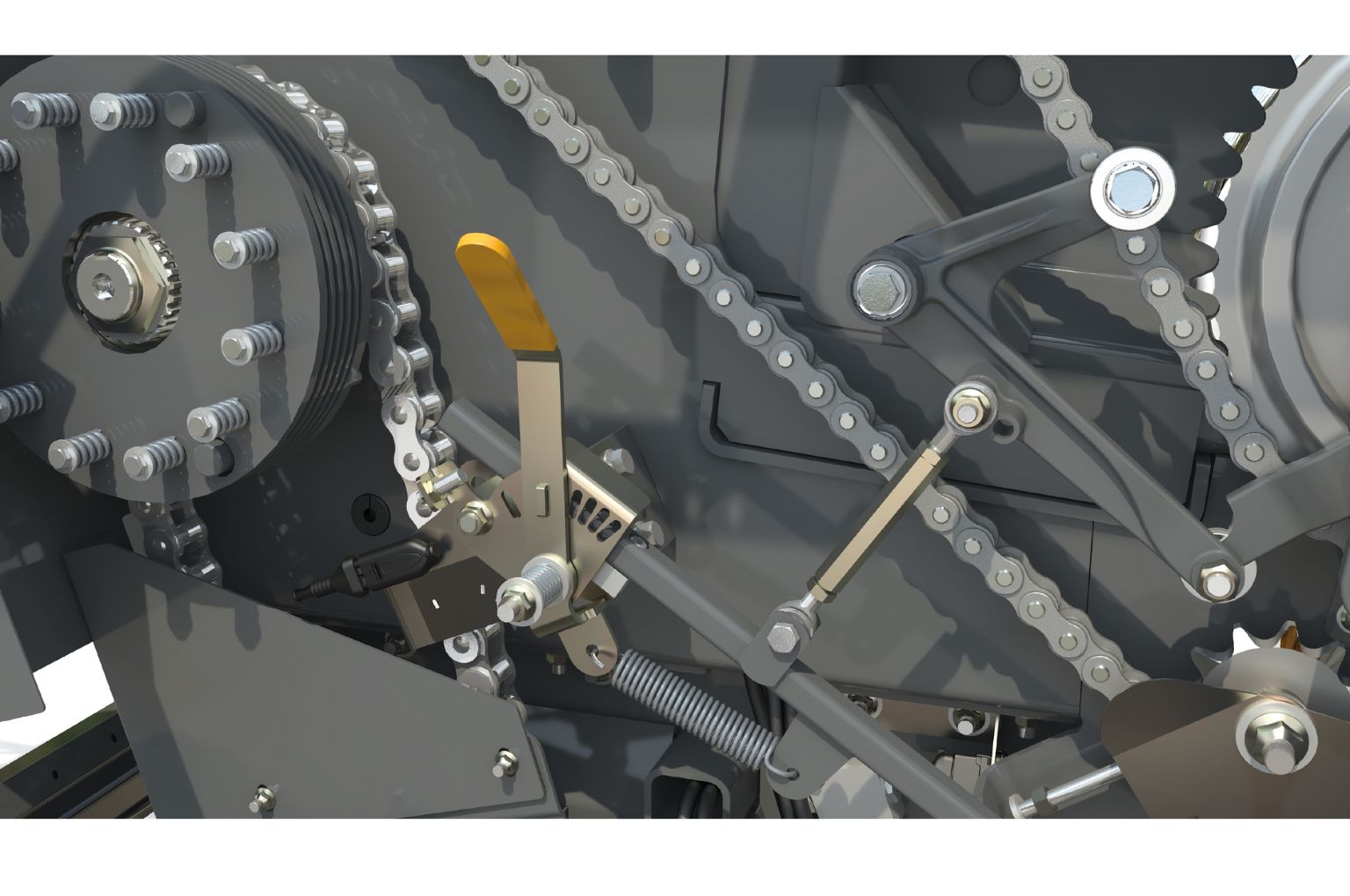

Durable and increased working comfort

The packer crankshaft bearings are now factory lubricated for life as standard. This reduces daily maintenance and increases service life. To further improve the longevity of the balers, the bale chamber and the pre-compression chamber have also been revised. The spring tension of the sensor flap in the pre-compression chamber can now be quickly and easily adjusted to the conditions by means of a lever – so that the bales can always be perfectly formed.

For more working comfort, the bale chute can be folded up from the tractor cab via the terminal. This reduces downtimes in the field, especially with frequent field changes. The resilient retaining straps are quieter and lighter than the previous chains.

Street, service and work lighting now comes as LED as standard.

Smart options for more working comfort

The electronics of the square balers have been comprehensively revised. This is accompanied by an update for the Bale Create user interface. In addition, all models measure the bale length precisely as standard. The intelligent electronic control monitors the bale length to ensure that they do not exceed the preset length. The optional twine monitor records the amount of twine used and provides a warning when the twine spool is running low. This reduces downtime and ensures reliably knotted bales. For the XD models, twine monitoring is a standard feature. The new electronics also enable the use of the Fendt Connect telemetry system and baling can be controlled through the use of TIM (Tractor Implement Management) which is incorporated into the baler.

Teamwork with TIM

With the help of TIM (Tractor Implement Management), the tractor adjusts to the requirements of the baler and increases the productivity of the tractor and baler combination. In conjunction with a TIM-capable tractor, the square baler controls the forward speed of the tractor according to the harvesting conditions and selected target parameters such as bale length, number of layers per bale, width of the individual layers or even bale weight. As a result, uniform bales are formed, the pick-up always operates at optimum capacity, the paring is always fully utilised and the driver can concentrate fully on monitoring the baling process.

Full connectivity with AGCO Connect

The central telemetry system AGCO Connect enables location-independent fleet management and optimisation of machine operations. AGCO Connect can read machine data such as machine utilisation, bale length and weight, machine speed and working time, as well as service information. This data is then displayed in the associated app or web application. Thus, the farm manager always has the machines in view.

After approval by the customer, the dealer may also access the machine data. By analysing error codes and upcoming service intervals from any location, downtimes can be reduced or avoided altogether and service appointments can be intelligently planned. Machine-related data is neither stored nor transmitted. The entire process is subject to the strict guidelines of the European General Data Protection Regulation (GDPR).

Transparency about bale quality with Bale Link

Bale Link is a system for collecting and processing information on each individual square bale. During the baling process, the baler records bale-specific data on the quality of the bale, its GPS position, bale moisture, the number of layers per bale, as well as information on the addition of additives and the dimensions of the bale. A special weather- and temperature-resistant twine with an RFID chip is woven into each bale during the baling process with the third or fourth twine. The chips are placed in the twine in such a way that one chip is woven into each bale up to 2.40 m in length. The RFID chip assigns an identification number to each bale and the information about each individual bale is stored in a cloud memory. Based on this information, bales can be stored and traded according to their quality.

To read the data on the bale, the RFID chip is scanned. The BaleLink app displays the corresponding data via smartphone, PC or tablet. Users can also share access to this bale data with traders or other farmers. This creates transparency about the bale quality at the time of sale.

Bale Link will be available in North American markets from model year 2023 and in Europe from model year 2024.

![RightSpot Ad Template Digital-1400×190-px[76] Ag Leader RightSpot](https://world-agritech.com/wp-content/uploads/elementor/thumbs/RightSpot-Ad-Template-Digital-1400x190-px76-r316mmc0hgoob9qxmklllnnbxta1nlj7t2vjkoyeek.png)