Tama, specialist in crop baling solutions from Israel, develops and produces netwrap, cotton wrap, baler twine, shade nets and turf nets for agriculture. After use, these usually remain as waste in the environment. Tama now recycles these products for re-use, thus reducing waste and protect the land.

Over the years, Tama has already reduced and re-used waste from its own manufacturing operations and looked at every stage of plastic production to develop more sustainable netwraps and twines. “We are aware of the fact that plastic is an essential part of agriculture in general and the baling industry in particular. And we understand that agricultural plastic waste is a challenge that urgently needs to be addressed: On a global scale, 60 percent of the total plastic waste are not treated to required standards”, explains Aviv Tron, Netwrap Sales & Marketing Product Line Manager and Tama Group Environmental Manager. He continues: “Even though net, twine etc. only account for a fraction of the total EU agricultural waste, which itself only accounts for 5 percent of all plastic waste in the EU in 2020, that clearly is an issue to address: Of 722 kilo tonnes agri-plastic that is placed on the EU market on a yearly basis, only 173 kilo tonnes are currently recycled”, Tron says.

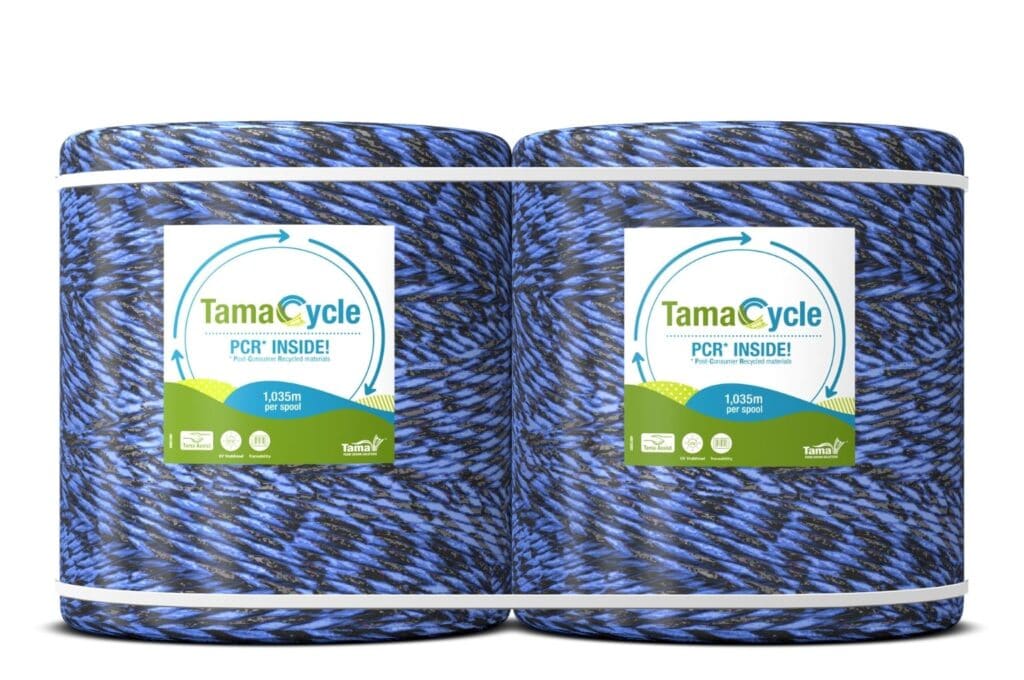

Ecological solution

Tama has set ambitious goals to be reached by 2025 as the company aims to be the world’s most efficient crop baling producer. The objective is to collect 50 percent of netwrap and twine as well as 90 percent of cotton wrap produced, and to increase the use of recycled plastics in Tama products to a minimum of 10 percent in netwrap, 30 percent in twine, and 20 percent in cotton wrap. Furthermore, the aim is to reduce the use of virgin plastics by 3 percent in netwrap, 20 percent in twine and 10 percent in cotton wrap. “In order to achieve these goals, Tama collaborates with a multitude of collection schemes around the world”, says Ewald Werschmann, TCE Commercial Manager and Europe Environmental Manager at Tama.

“We have implemented a collection and recycling process in cooperation with Adivalor in France and Healix in the Netherlands. This starts on the farms with the removal, shaking (i.e. cleaning) of netwrap and twine and the subsequent collection via Adivalor. The plastic waste is then taken to the Healix recycling plant in Maastricht, The Netherlands, where it is further cleaned and re-processed into high-quality infinity polymers”, explains Werschmann. These polymers are then repacked and shipped to Tama’s factories and return to the fields as new crop baling products.

The new high performance netwrap and twine are used in significant percentages of recycled content, have been and are tested all over the world. “These products are compatible with all balers and definitely offer the same performance and quality as other Tama crop baling products”, concludes Werschmann.

Watch Video