Claas Industrietechnik in Paderborn, Germany, looks back on 25 years of development and production of its own Terra Trac crawler track systems and 35 years of Terra Trac experience.

The summer of 1997 not only marked a milestone for Claas in combine harvesting technology, but also for the broad market acceptance of soil-protecting tracks on self-propelled harvesters. Since then, the friction crawler track systems developed and extensively tested by Claas Industrietechnik (CIT) in Paderborn have been the standard and benchmark in the industry.

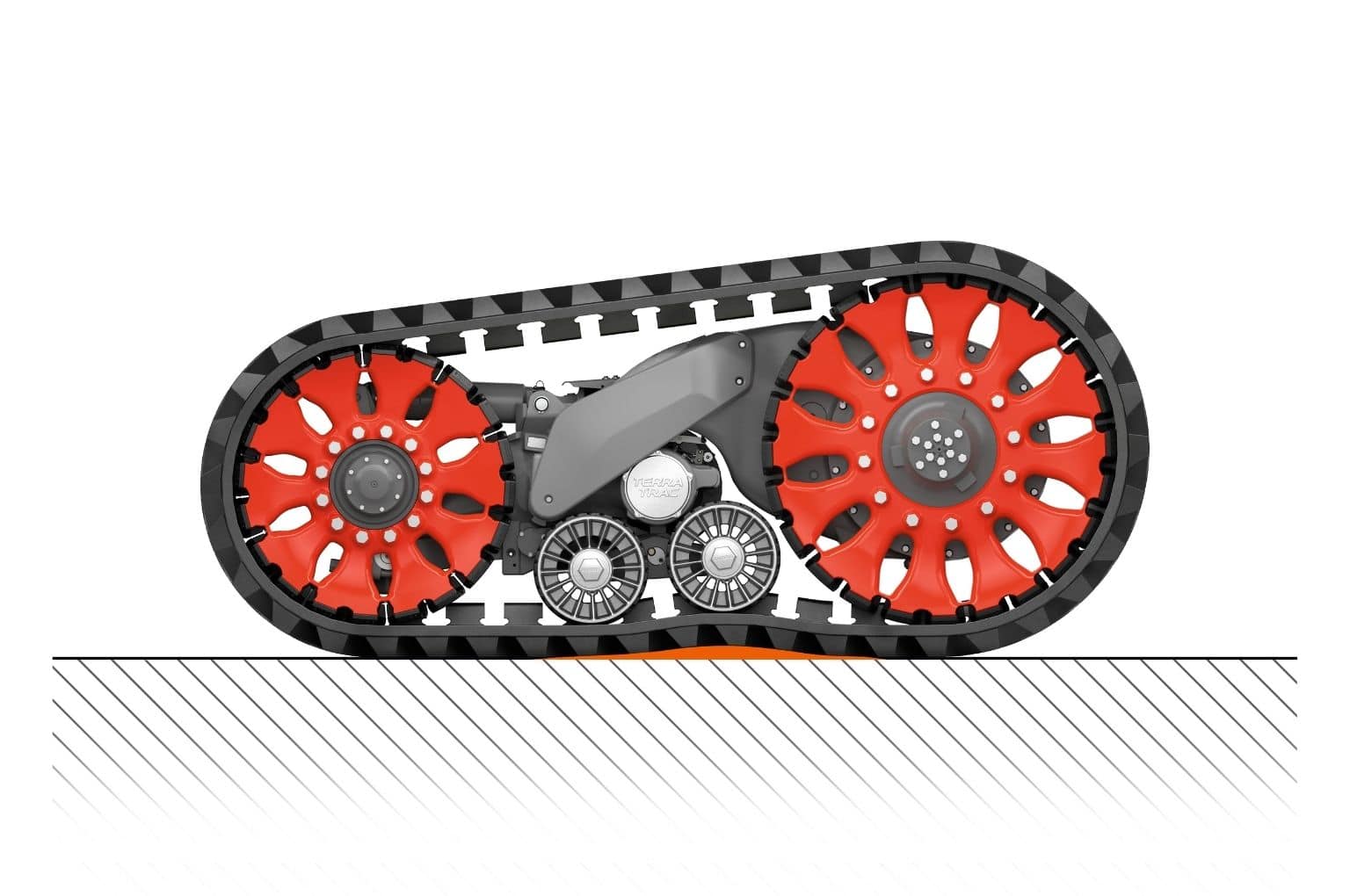

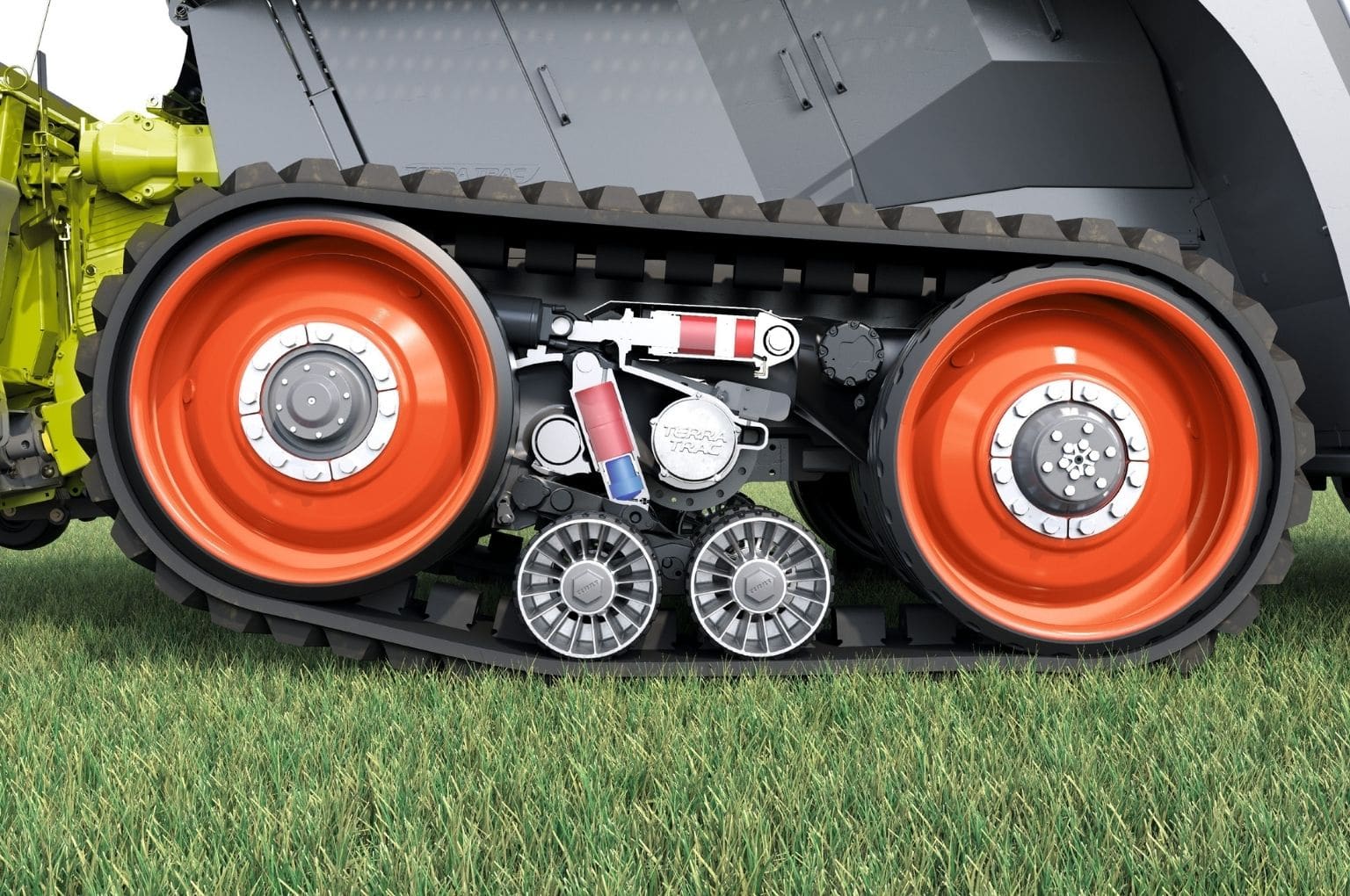

Initially available for the Lexion combine harvester, further development progressed rapidly. In 2004, driving comfort was significantly improved by the introduction of rubber shock absorbers on the axles of the running gear, which until then had been rigidly mounted. The development of hydro pneumatic suspension marked a quantum leap, which distinguished the new Terra Trac generation in 2011 and still provides excellent comfort characteristics to this day. This enabled significantly improved ground tracking, and a driving speed of 40 km/h on the road could be achieved.

“After initial skepticism, we were able to convince farmers and contractors of the advantages of Terra Trac technology,” remembers Dr. Ulf Leinhäuser, CEO of Claas Industrietechnik Paderborn. “Whereas the number of machines fitted with Terra Trac crawler track systems was initially just over 10 percent, today it is more than 50 percent for the Lexion alone. In North America, more than 70 percent of the Lexion are delivered with our crawler track systems, while in Great Britain it’s more than 90 percent.”

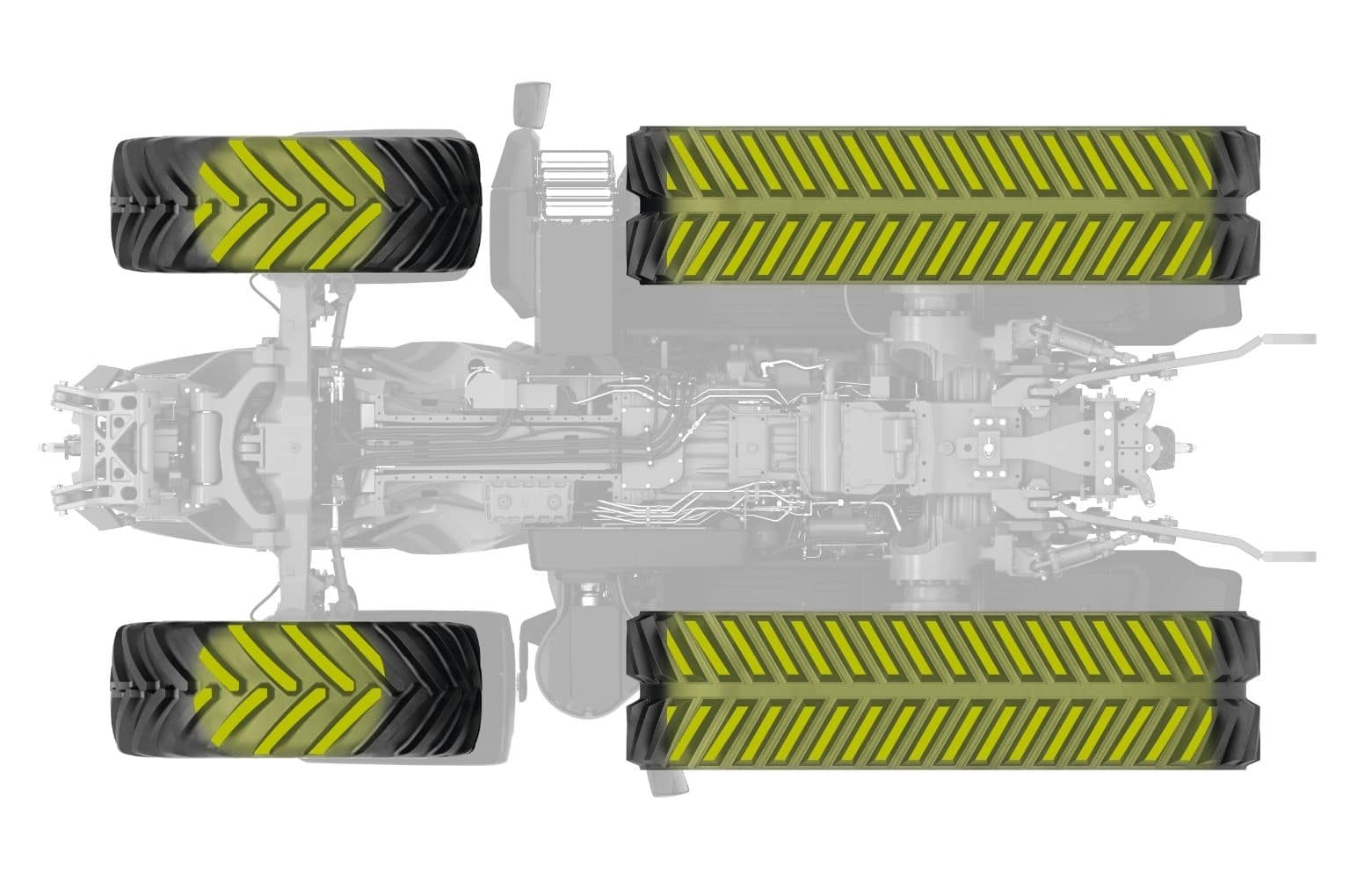

The Terra Trac drives continue to be further developed. In 2019, Claas expanded the range of high-performance combines available with Terra Trac technology with the introduction of the Lexion 5000/6000/7000/8000. In the same year, series production of the Axion Terra Trac, which was shown as a concept at Agritechnica in 2017, began with two models. The Axion is still the only full-suspension half-track tractor on the market. At the end of 2018, Claas also added two Jaguar forage harvesters with integrated crawler track systems to its product portfolio. These are fitted with drives that incorporate a patented headland protection system that allows the contact area of the drives to be reduced when turning at the headland, so bringing the benefits of Terra Trac to grassland and other sensitive areas.

The newest member of the Terra Trac family at Claas is the Trion combine harvester. Launched in 2021, for the first time this includes the option of a medium-sized 5-walker model with Terra Trac, ex works from Paderborn.

35 years of experience

However, Claas’ experience with soil-protecting tracks goes back a further 10 years, to 1987. “At the Farm Progress Show in the USA, Claas showed the Dominator CS with two Caterpillar tracks,” says Robert Obermeier-Hartmann, Senior Manager Product Strategy & Advanced Development. Because its overall width was more than 4.00m, the machines were mainly reserved for the North American market, so only a few were used in Europe – for example in Great Britain. “Looking back, the driving comfort was very poor due to the lack of suspension,” adds Robert Obermeier-Hartmann. “With our current Terra Trac crawler track systems, we are moving to a completely different level. In the field and increasingly also when driving on the road, our bogies are superior to classic wheeled bogies in many respects and also when it comes to driving comfort.”

Technology and experience have also been valued by external customers for many years. Terra Trac crawler track systems from Claas Industrietechnik can be found on self-propelled beet harvesters and vegetable harvesters, but also on self-propelled and towed potato harvesters. Further fields of application are liquid manure spreading tanks with Terra Trac crawler track systems and Active Drive drive axle. Thanks to the additional “boost”, a lighter tractor with less traction is sufficient, the wheel slip of which can also be significantly reduced by the drive axle under the carriage. The interaction of less weight, less wheel slip and the large contact area protects the ground in a previously unknown way.

To date, Claas Industrietechnik in Paderborn has manufactured and marketed 35,000 Terra Trac running gears in Paderborn.

Milestones of Terra Trac technology at a glance

– 1997: Introduction at Claas Lexion combine harvesters

– 2004: Introduction of rubber shock absorbers for increased driving comfort

– 2006: 2nd generation Terre Trac with a reinforced frame cast in one piece for the new Lexion 600

– 2011: Introduction of hydro pneumatic suspension and 40 km/h top speed

– 2017: Axion Terra Trac tractor as a concept at Agritechnica

– 2018: Introduction of two Jaguar Terra Trac models with a unique headland function

– 2019: Start of series production of two Axion Terra Trac models

– 2019: Presentation of the Lexion 5000/6000/7000/8000 with ten Terra Trac models

– 2021: Introduction of the Trion combine harvester series with six Terra Trac models

– February 2022: Jaguar Terra Trac no. 100 rolls off the assembly line in Harsewinkel

– …next stop: Agritechnica 2023

Current Terra Trac undercarriages for the following Claas series:

– Axion 930/960

– Jaguar 960/990

– Lexion 5000/6000/7000/8000

– Trion 500/600/700