Claas telehandlers in the lower and mid-range performance class will in future be powered by a highly efficient twin motor. The familiar, compact drive unit from the Jaguar forage harvesters promises a long service life, improved drive efficiency and reduced noise levels.

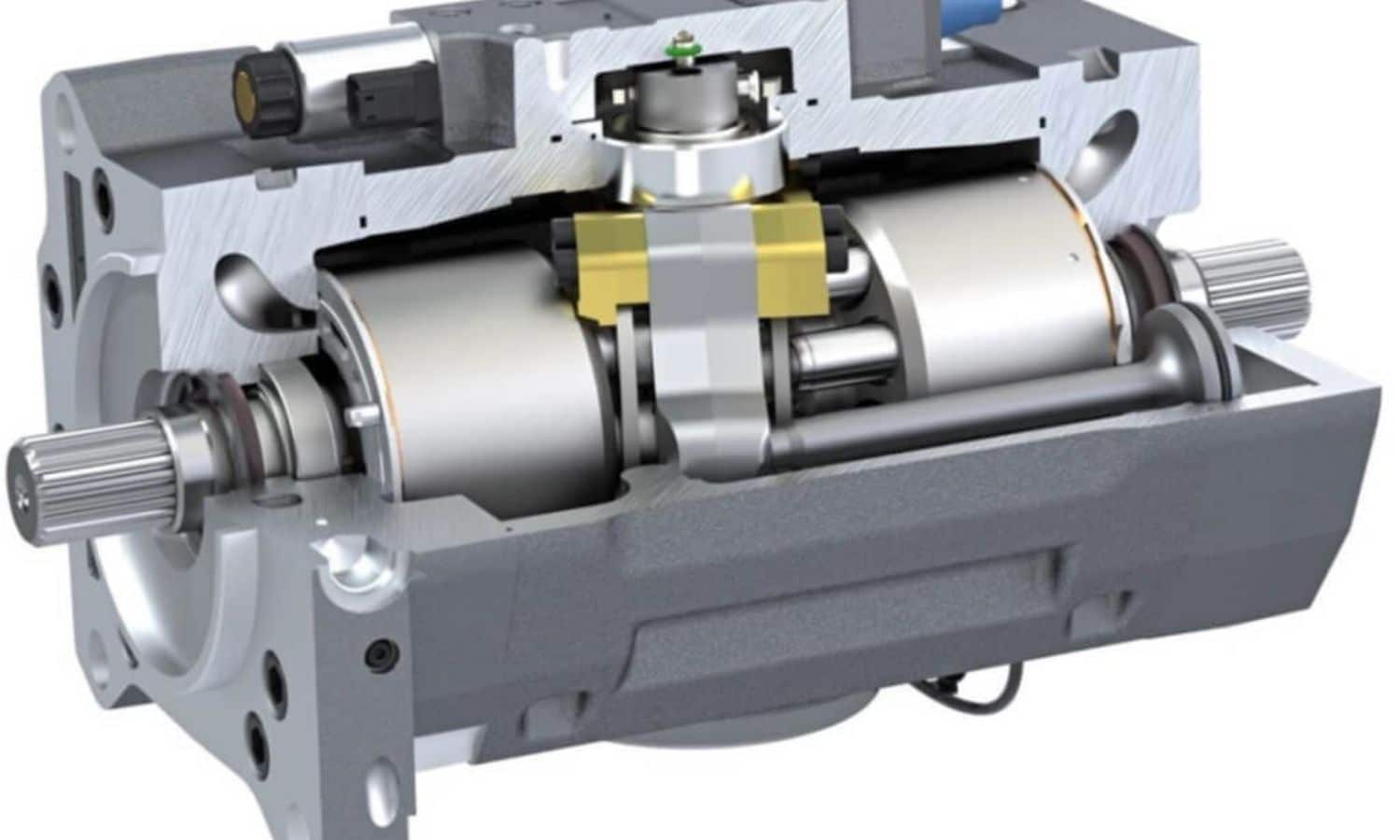

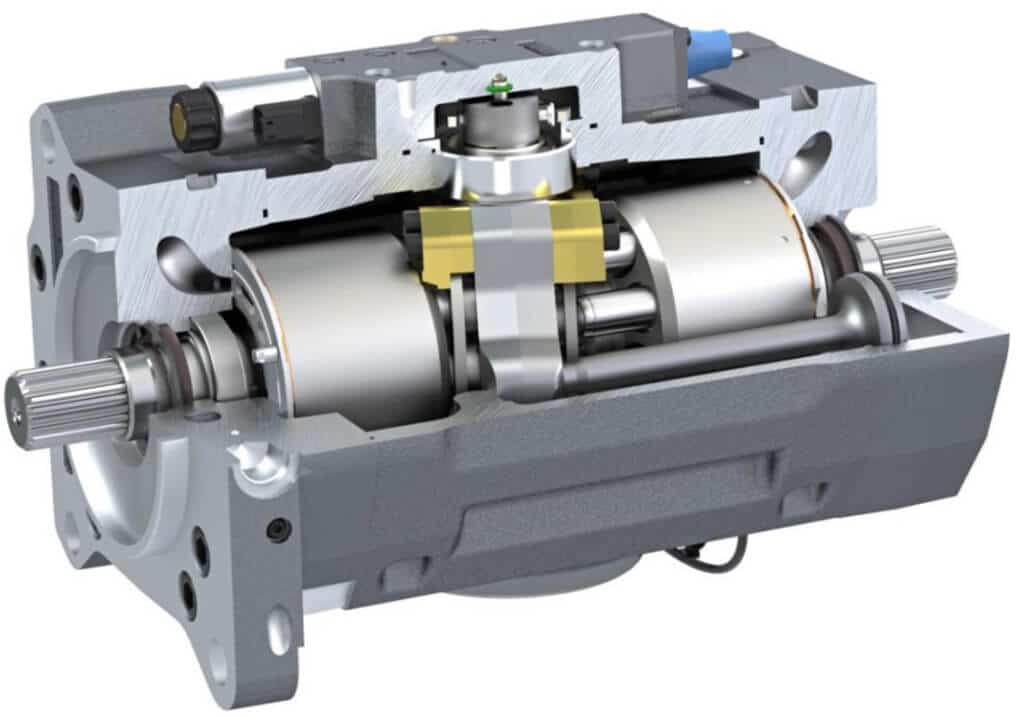

The “Varipower drive” in the Scorpion 741, 736, 635, 1033 and 732 has now been replaced with the “Varipower 2” twin motor, designed and manufactured exclusively for Claas. The drive integrated into these models as standard comprises two hydrostatic motors inside a compact housing which share a common shaft and swash plate and have been used successfully in the Claas forage harvesters for several years. Both motors have a maximum swivel range of 23 degrees, with both traction units controlled by a common distribution unit.

As before, the operator can select three driving ranges – 0 to 15 km/h, 0 to 30 km/h and 0 to 40 km/h – with the simple press of a thumb. A maximum speed of 40 km/h is standard, but there is an option to limit this to 30 km/h or 20 km/h as required. In each case the top speed is reached at a reduced, fuel-saving engine speed.

Varipower 2 transfers just as high torque to the wheels as the previous Varipower drive. The simple, compact design, which dispenses with the need for transfer gears, ensures a high level of wear tolerance and long service life. The new feature is that the housing oil is continuously extracted from the drive housing by a powerful Venturi tube, which significantly reduces churning losses when driving at speed. This ensures maximum efficiency and low fuel consumption even on fast road journeys.

The Scorpion 960, 756 and 746 will continue to work with the Varipower (746) and the high-performance Varipower Plus drive (756, 960) with wide-angle hydrostatic pump and second displacement motor.

New cameras and other features

Two latest generation Claas cameras are optionally available for all Scorpion models. These can be mounted at the rear and on the telescopic arm or hitch frame and are housed inside a new holder for optimum protection. The image is transferred to a separate display in the cab, which switches automatically to the rear camera when reversing. This greatly increases safety and convenience for the operator. Integrated heating inside the camera housing prevents the lens from misting up or freezing when the weather is cold or wet.

A new four-digit counter is available within easy reach of the joystick for manually counting load cycles. Other new features include an LED flashing beacon, self-cancelling indicators and additional tyre options. The rear of the vehicle can now be accessed without tools.

Production line in Telfs

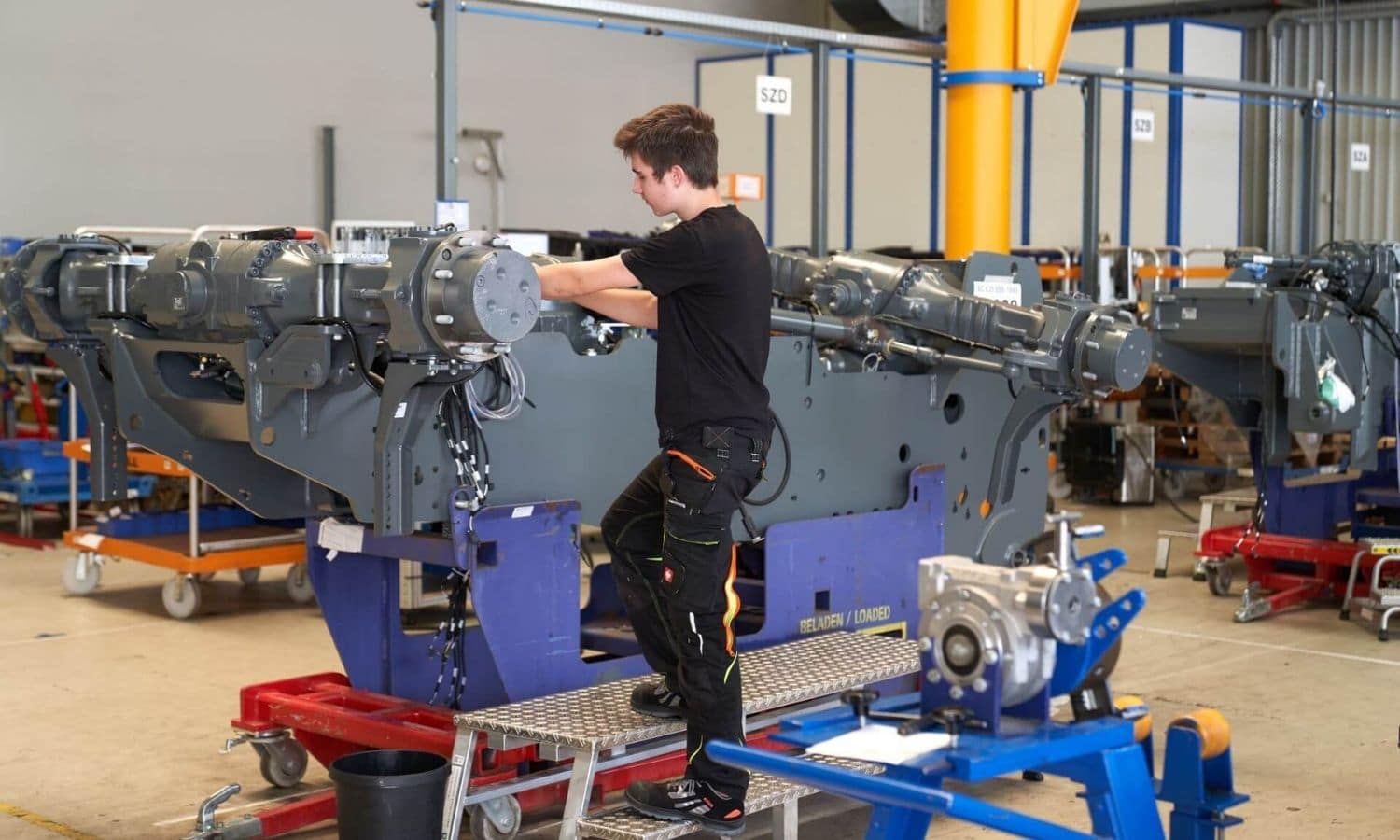

Claas Scorpion telehandlers are manufactured at the Liebherr plant at Telfs in Austria. Continuous investment in the plant has enabled production processes here to be tailored to growing customer requirements and the increasing complexity of the machines. It has been possible to increase capacity, especially in the quality assurance sector, by extending the assembly line and installing a second light tunnel.

Claas telehandlers are assembled on one level without using forklift trucks in accordance with the latest developments in ergonomics. One particular highlight is the frame turning device, which provides 360° access at body height for assembling the axles, for example. In the cab pre-assembly section, every single function of the custom-built cabs is tested in a state-of-the-art cab test rig using an automated testing process.